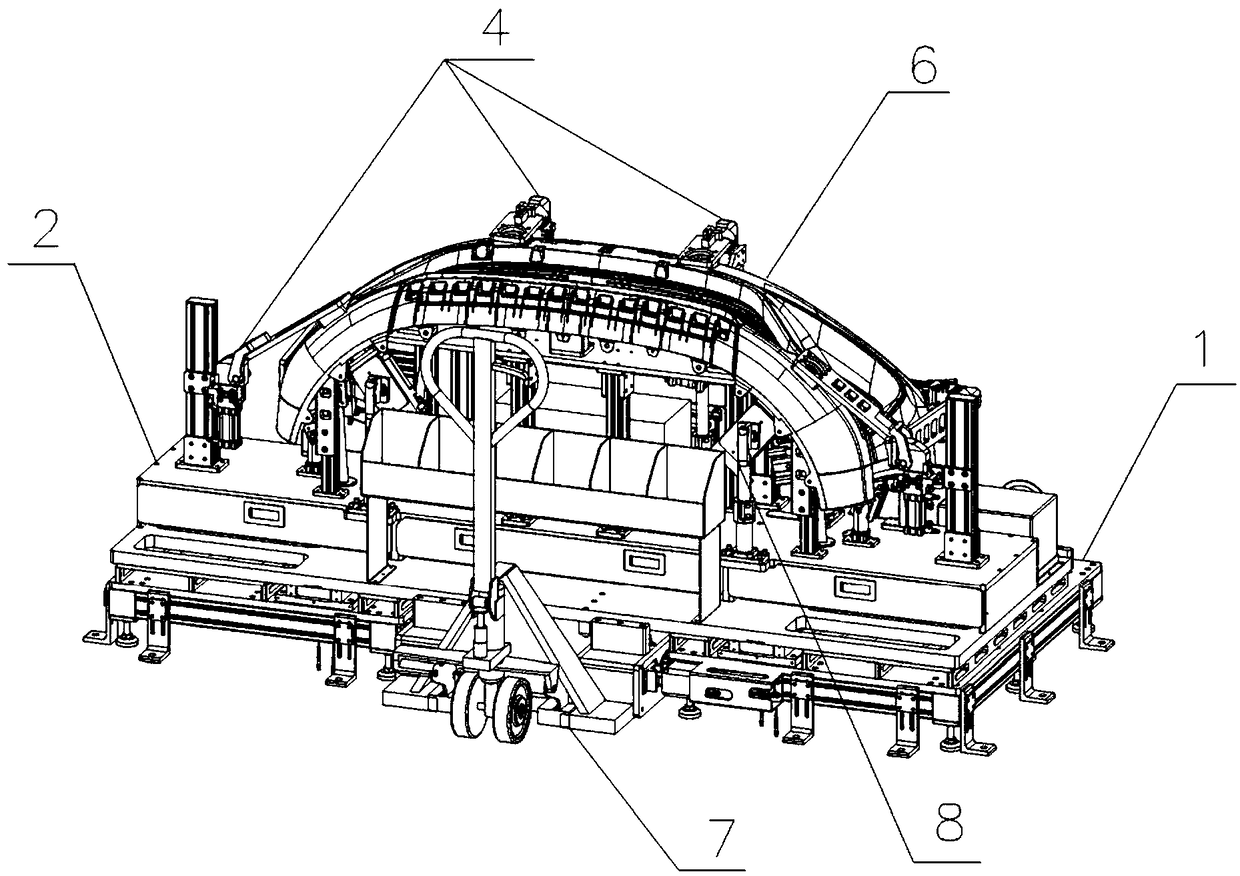

Intelligent clamp and control method thereof

A fixture and intelligent technology, applied in the field of intelligent fixture and its control, can solve the problems of large working space, poor dust removal effect, affecting equipment performance and production environment, etc., and achieve good effect of dust removal and waste removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

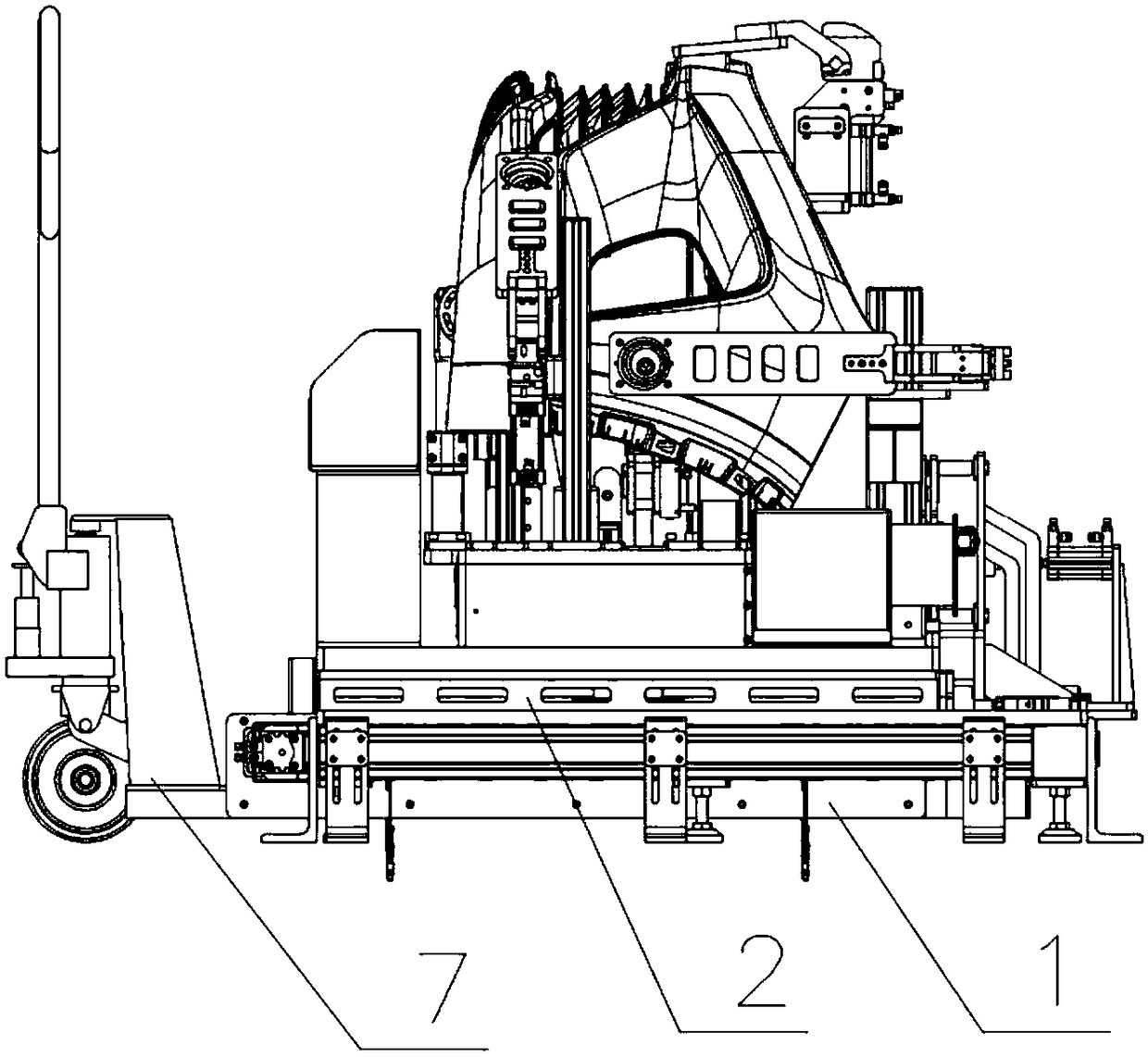

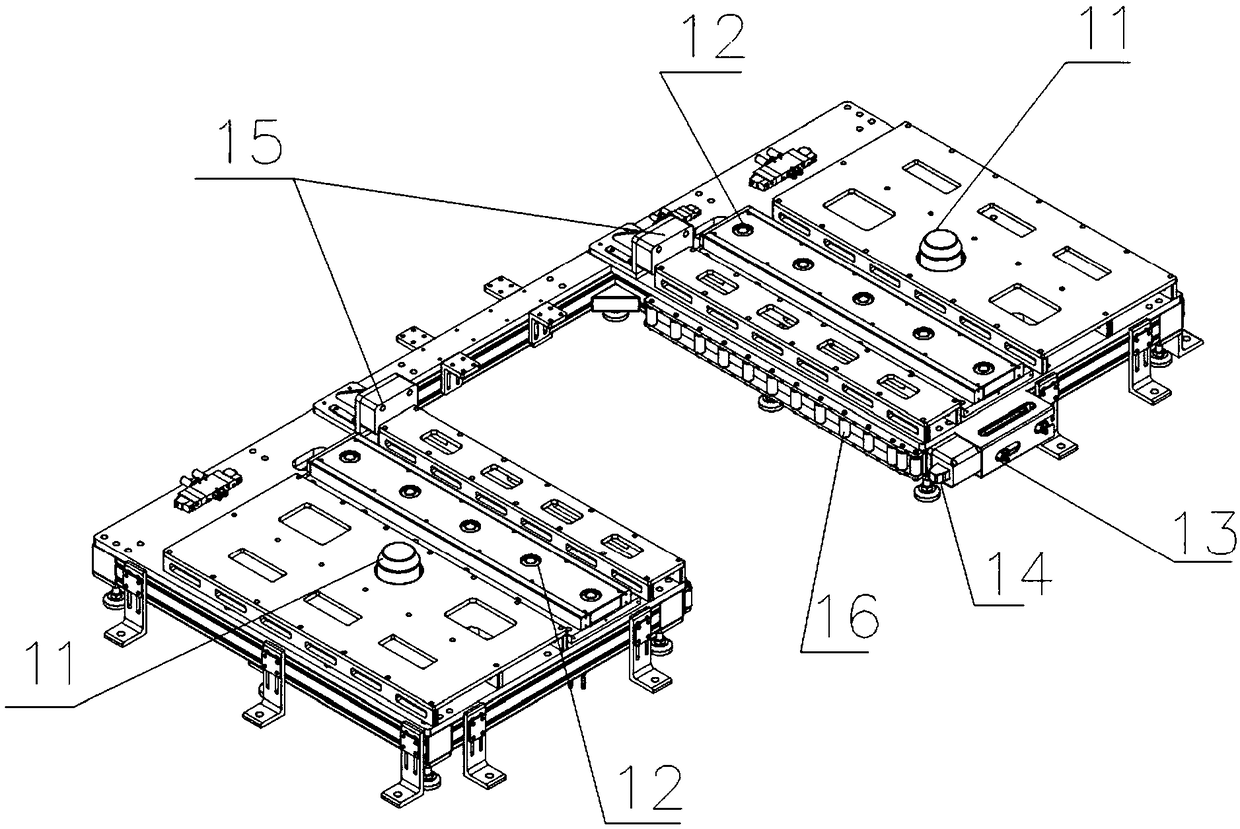

Embodiment 1

[0056] 1) The fixture body is in place: first call the corresponding fixture body 2 according to the number of the workpiece 6, manually use the special forklift 7 to transport the fixture body 2 to the base 1, and the special forklift 7 enters the position between the two rectangular bases, When the front side of the clamp body 2 touches the anti-collision block 15 on the base 1, the special forklift 7 stops moving forward. During this period, the positioning mechanism 13 on one side of the base 1 cooperates with the positioning groove 71 on the special forklift to complete the locked positioning of the special forklift 7, and thus completes the initial positioning between the clamp body 2 and the base 1; then the central control system Control the rise of the universal ball 12 on the base 1, stop rising when the apex of the universal ball 12 touches the bottom of the fixture body 2, then manually control the special forklift 7 to descend, and the weight of the fixture body 2 ...

Embodiment 2

[0062] Application example of the intelligent fixture of the present invention in the radar hole cutting and radar bracket installation process of the automobile bumper: in the prior art, the radar hole cutting and the radar bracket installation on the automobile bumper are usually completed by two processes successively , in the embodiment of the smart fixture of the present invention, only a simple improvement to the fixture body 2 is needed to combine the cutting of the radar hole and the installation of the radar bracket into one process, which can improve work efficiency. The improvement scheme is as follows: the above-mentioned improvement can be completed by adding a radar support push assembly on the existing fixture body 2. The radar support push assembly 8 is composed of a support seat 81, a sensor 82, a push mechanism 83 and a radar support column 84. The radar support pushes Component 8 is fixedly installed on the upper surface of waste material collection chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com