Electromagnetic geomembrane welding device

A technology of welding equipment and geomembrane, which is applied in the field of high-efficiency electromagnetic geomembrane welding equipment, can solve problems such as water leakage, unreliable crimping, and uneven ground of the geomembrane, and achieve simple switching methods, reduced friction, and heating high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

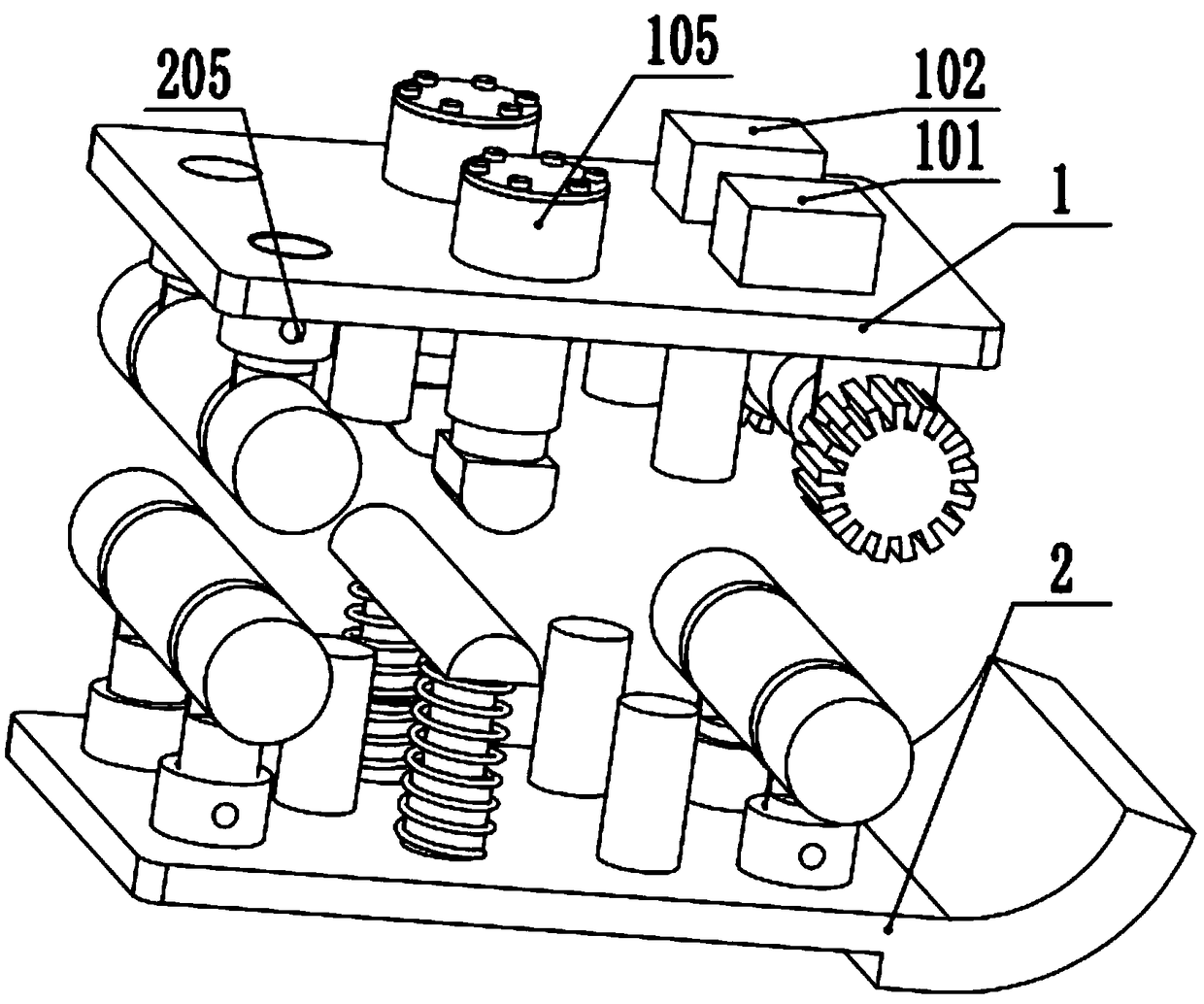

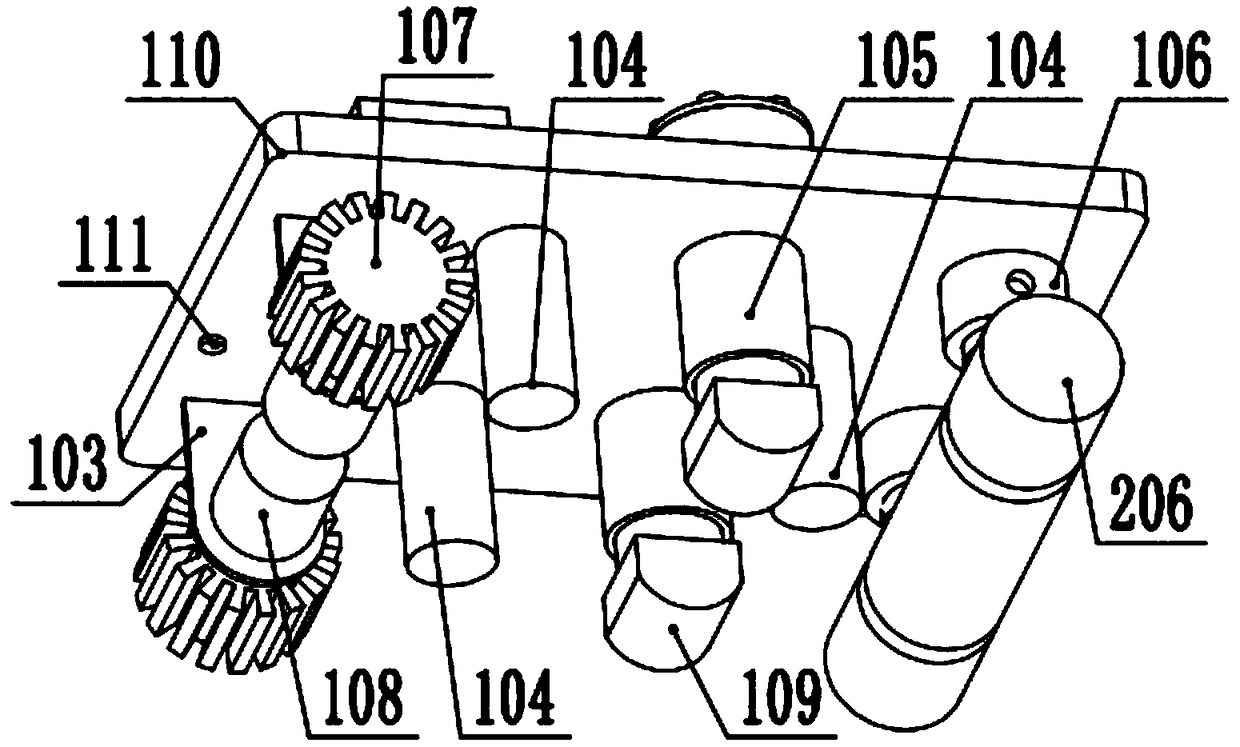

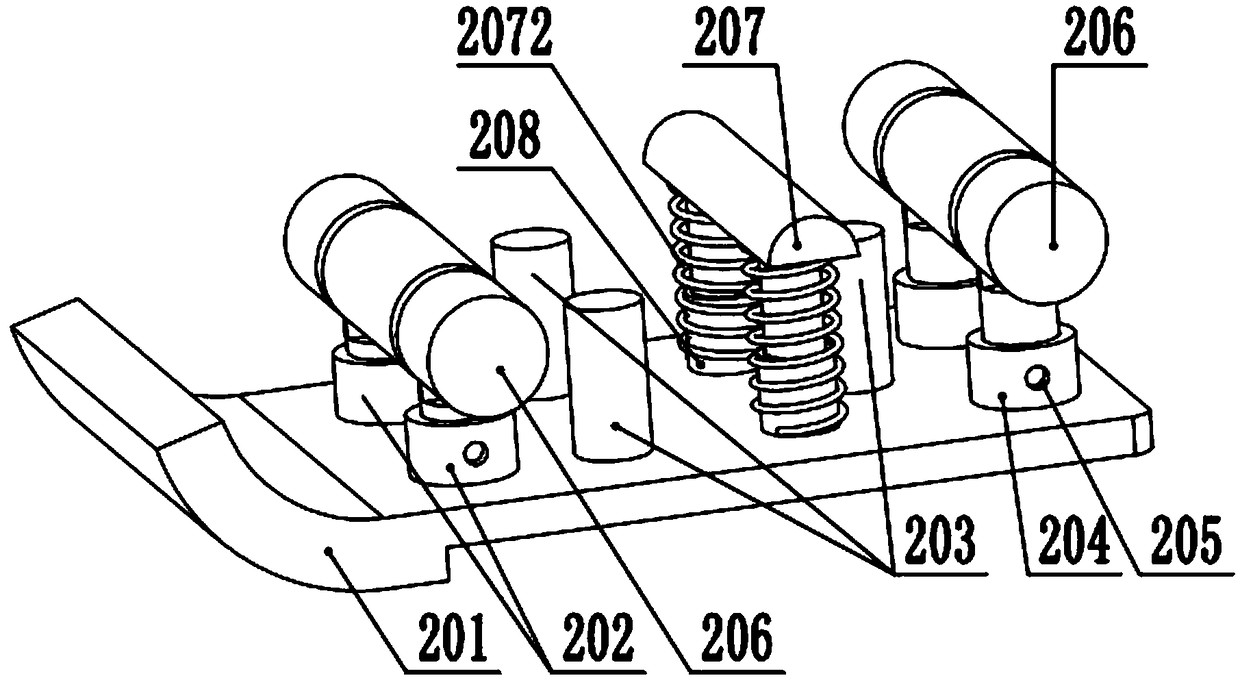

[0036] An electromagnetic geomembrane welding equipment, comprising an upper traveling mechanism 1 and a lower traveling mechanism 2, the upper traveling mechanism 1 includes an upper plate 110, and the lower plane of the upper plate 110 is provided with a drive wheel 107 for controlling the walking direction Controller 101, eddy current heater 109, magnetic part 104; the quantity of magnetic part 104 is determined according to the total weight of lower plate 201 and its components, generally selects 2-5, and the shape of magnetic part 104 generally adopts cylindrical shape. The overlapping layers of the geomembrane that need to be welded or crimped are sandwiched between the upper traveling mechanism 1 and the lower traveling mechanism 2 .

[0037] The lower traveling mechanism 1 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com