Production method for polyethylene double-crest reinforced spiral winding pipes

A technology of a spirally wound pipe and a production method, which is applied to the production field of a polyethylene reinforced spirally wound double-wave corrugated pipe for water supply and drainage, and can solve the problems of insufficient strength of bonding seams and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

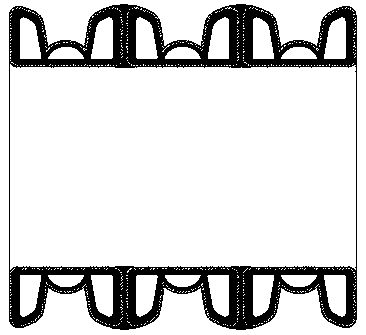

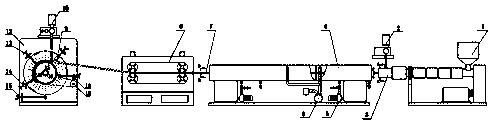

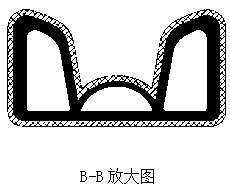

[0039] A production device for polyethylene double-peak reinforced spiral wound pipe, the production device refers to an extrusion winding molding production line, and the extrusion winding production line includes a recycled polyethylene twin-screw extruder 1, a polyethylene double-peak reinforced profile package Covering extruder 2, co-extrusion die for double-wave reinforced profile 3, vacuum setting cooling water tank 4, water pump 5, vacuum pump 6, polyethylene double-peak reinforced profile 7, tractor 8, hot air heating device 9, glue melting extruder 10 , melt glue layer 11, winding frame 12, radial pressure roller 13, axial baffle 14, pipe pitch adjustment device 15, winding roller transmission device 18, chain tensioning wheel 19, winding roller 16, winding machine spindle 17, Mouth 2-1, left high half peak core mold 2-2, right high half peak core mold 2-3, middle low peak core 2-4, molten regenerated polyethylene 2-5, molten coated polyethylene 2 -6; The connection r...

Embodiment 2

[0047] The winding machine is to wind and bond the polyethylene double-peak reinforced spirally wound pipe in a clockwise direction when the inner diameter of the polyethylene double-peak reinforced spirally wound pipe is 200 mm.

Embodiment 3

[0049] The winding machine is to wind and bond the polyethylene double-peak reinforced spirally wound pipe in a counterclockwise direction when the inner diameter of the polyethylene double-peak reinforced spirally wound pipe is 1000 mm.

[0050] The rest is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com