Sedan outer tire patch

A patch and car technology, applied in the field of tire repair, can solve problems such as poor bonding effect, reduced tire service life, waste of resources, etc., and achieve the effect of avoiding secondary cracking, avoiding waste of resources, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

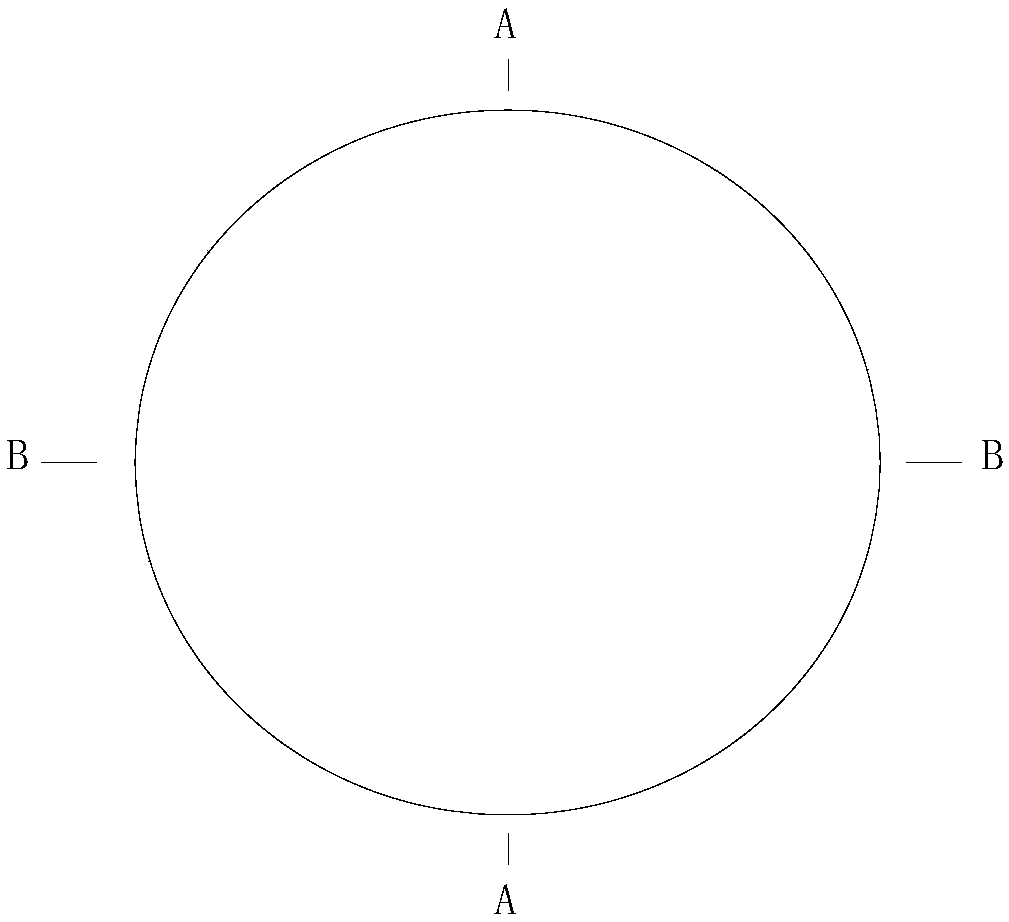

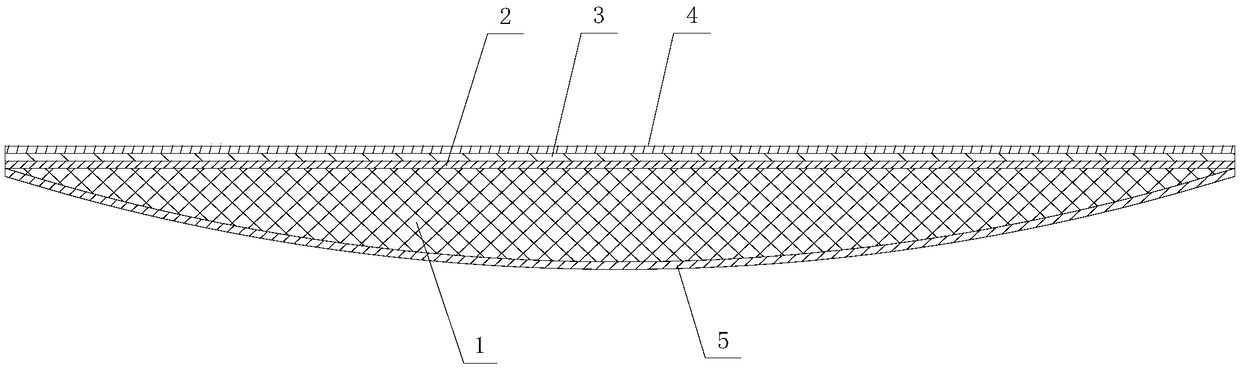

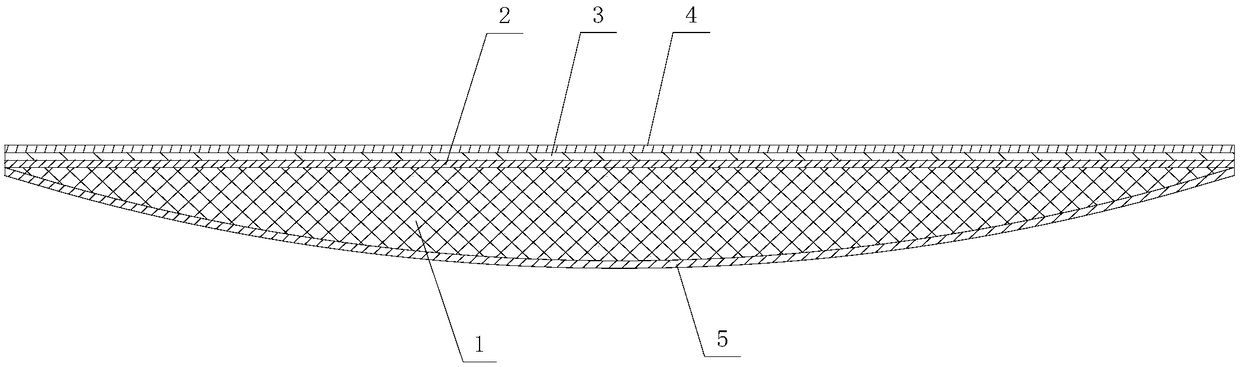

[0018] Such as Figure 1 to Figure 3 Shown, a kind of car tire patch, described patch is circular, and its top surface is plane, and bottom surface is the curved surface that protrudes downwards. That is, the thickness of the patch gradually decreases from the middle to the peripheral edge.

[0019] Further, the patch includes a patch body 1, the top surface of the patch body 1 is provided with a polishing layer 2, an unvulcanized low-temperature vulcanized rubber layer 3 and a protective film 4 sequentially from bottom to top, and a vulcanized layer 5 is provided on the bottom surface. Moreover, the patch body 1 is made of waste tire sidewall rubber. The above-mentioned setting of the grinding layer 2 is beneficial to the tight connection between the low-temperature vulcanized rubber layer 3 and the patch body 1 . In the manufacturing process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com