A kind of continuous preparation method of 1,1,1,2,3-pentachloropropane

A technology of pentachloropropane and trichloropropene, which is applied in the field of preparation of chlorinated alkanes, can solve the problems of unfavorable environmental protection and industrial production application, low reaction selectivity, short catalyst life, etc., to avoid uneven heat exchange effect, The effect of high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

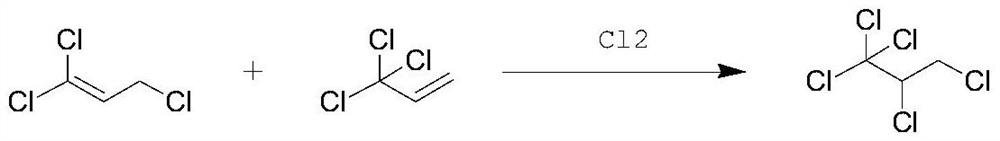

Image

Examples

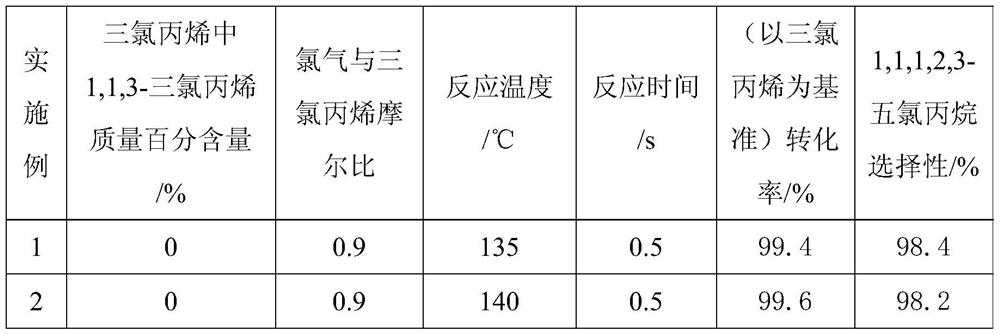

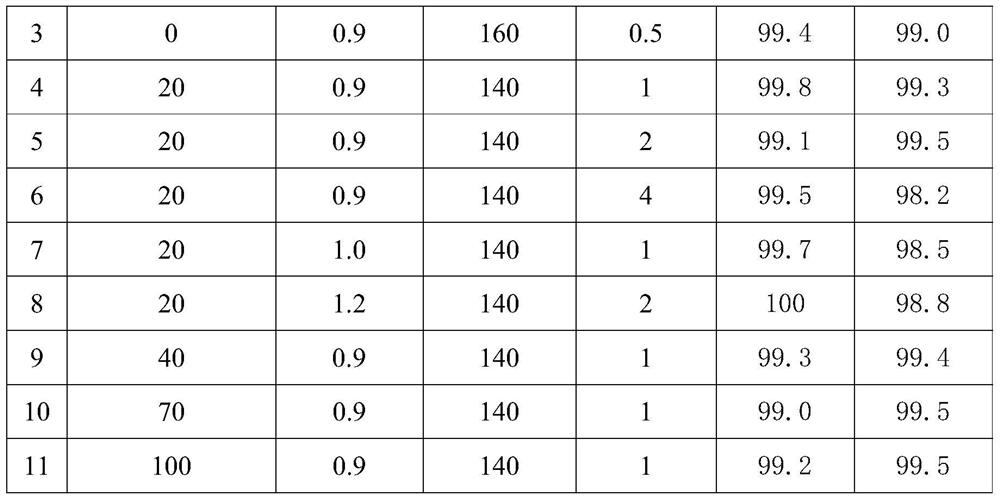

Embodiment 1~11

[0031] According to the required reaction molar ratio and residence time, set the flow rate of trichloropropene (1,1,3-trichloropropene or 3,3,3-trichloropropene or their mixture) and chlorine, and flow them to Input trichloropropene and chlorine gas into trichloropropene preheater and chlorine gas preheater, the temperature of trichloropropene preheater and chlorine gas preheater is set at 135~140 ℃, the preheated trichloropropene and chlorine gas enter micro The reaction is carried out in the channel reactor, and the reaction product is collected, cooled and rectified under reduced pressure (vacuum degree 0.099MPa), and the fraction at 76-78°C is collected to obtain 1,1,1,2,3-pentachloropropane product (purity 99.8%) . Sampling and analysis were taken from the outlet of the microchannel reactor. The experimental results of different reaction conditions are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com