A self-heating circular methanol reforming reactor for hydrogen production

A technology of reforming reaction and reforming hydrogen production, which is applied in the fields of hydrogen, chemical instruments and methods, hydrogen/synthesis gas production, etc., and can solve problems such as difficult sealing and different reaction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

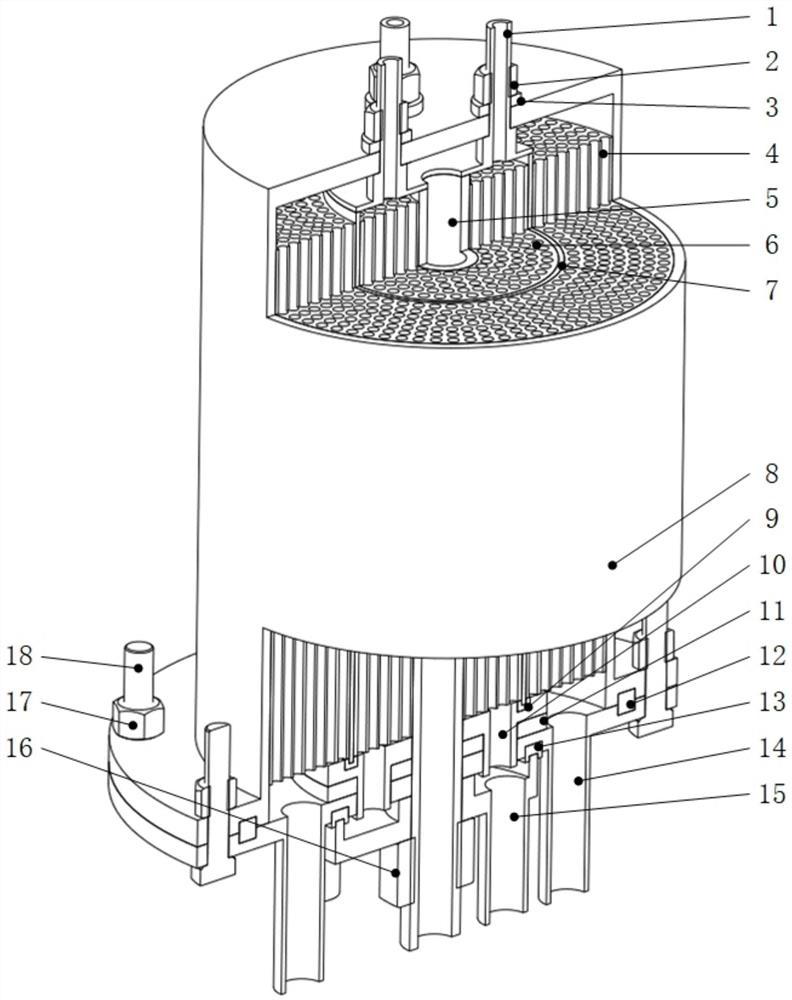

[0054] Such as Figure 9 As shown, there are two gas paths in the reactor: methanol catalytic combustion and methanol steam reforming.

[0055] The first gas path is the catalytic combustion of methanol. Methanol and air enter the gas buffer chamber from the gas buffer chamber inlet pipe 31 of the gas buffer chamber cover 15, and then enter the combustion chamber evenly through the combustion reactant inlet pipe 26, and the reactants flow in the combustion chamber. When passing through the honeycomb silicon carbide, the catalytic combustion reaction occurs under the action of the methanol catalytic combustion catalyst, and the released heat provides heat for the endothermic reaction in the reactor and maintains the required working temperature of the reactor.

[0056] The second gas path is methanol water vapor reforming, methanol aqueous solution enters from the bottom of the evaporation chamber tube 5, and completes the vaporization and preheating of the reactants surrounded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com