A corrugated substrate-porous metal self-heating methanol reforming hydrogen production reactor

A porous metal, reforming hydrogen production technology, applied in the direction of non-metallic elements, hydrogen, chemical instruments and methods, etc., can solve the problem of reducing the dynamic response speed and mass power density of the system, without considering the reaction rate and catalyst requirements, reactors The thickness of the substrate and other issues can be reduced to reduce the start-up and response time, reduce structural redundancy, and reduce thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

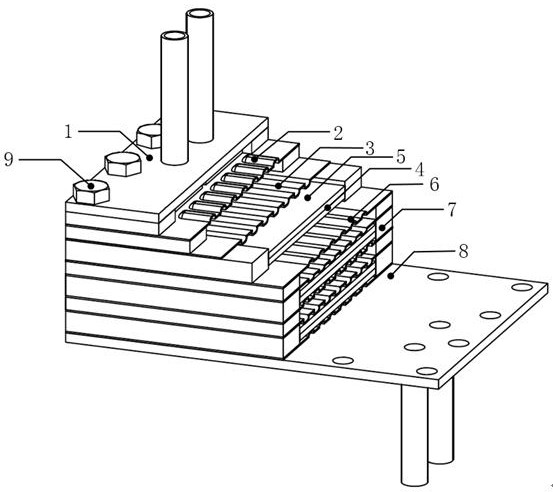

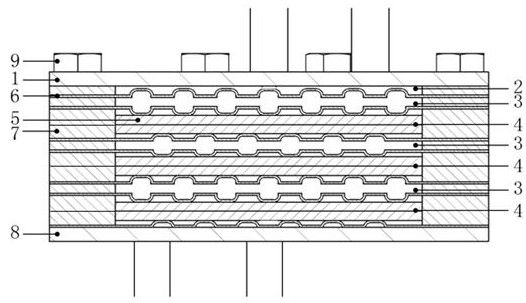

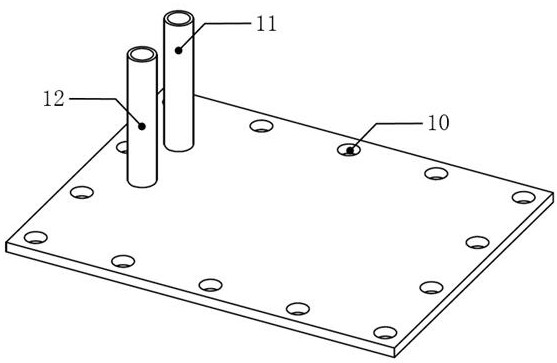

[0036] Such as figure 1 , figure 2 As shown, the reactor of the present invention includes an upper cover plate 1 sequentially from top to bottom, a corrugated substrate with multiple sets of convex arrays with the same structure stacked upwards and convex arrays downwards, and two stacked porous metal plates. Structural unit, the lower cover plate 8, graphite gaskets 7 are placed around the adjacent plates, and the bolt holes 10 around each plate are connected into a whole with fastening bolts 9; The evaporation chamber 2 is formed between the cover plates 1, and the first methanol catalytic combustion chamber is formed in the corrugated substrate with the convex array upward and the convex array downward, and the corrugated substrate with the convex downward and the convex upward is welded on it The first methanol water vapor reforming chamber is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com