A kind of quinoa peptide and its preparation method and application

A technology of quinoa peptide and quinoa, which is applied in the field of quinoa peptide and its preparation, can solve the problems of failing to reflect the degree of proteolysis or peptide yield, affecting the efficiency of enzymatic hydrolysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

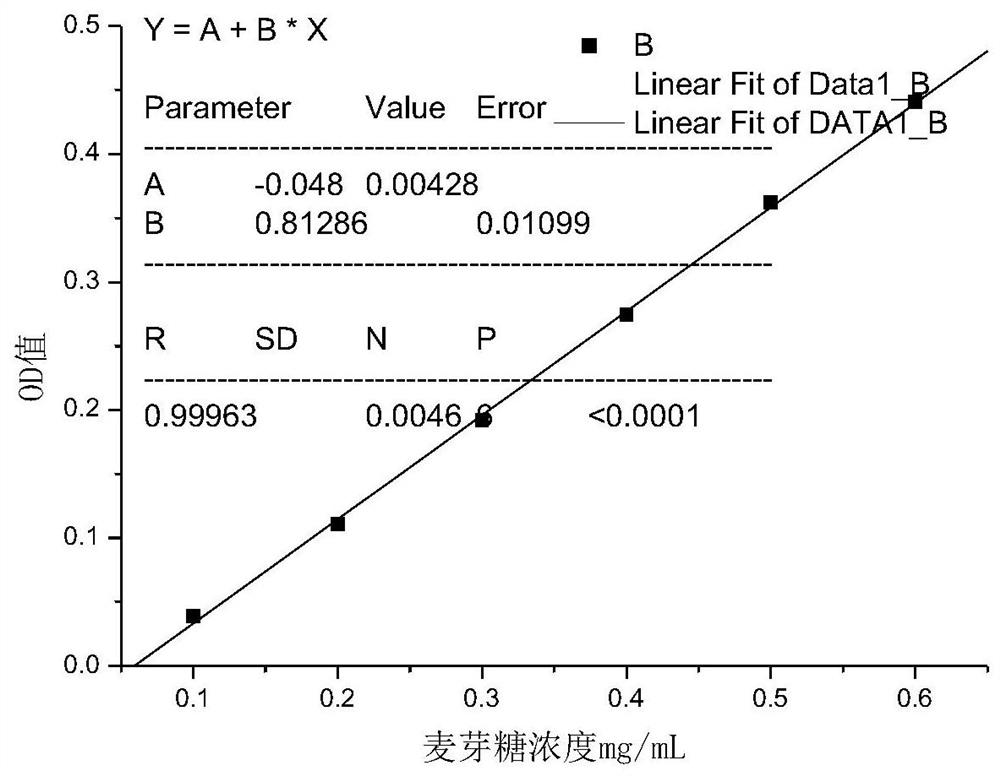

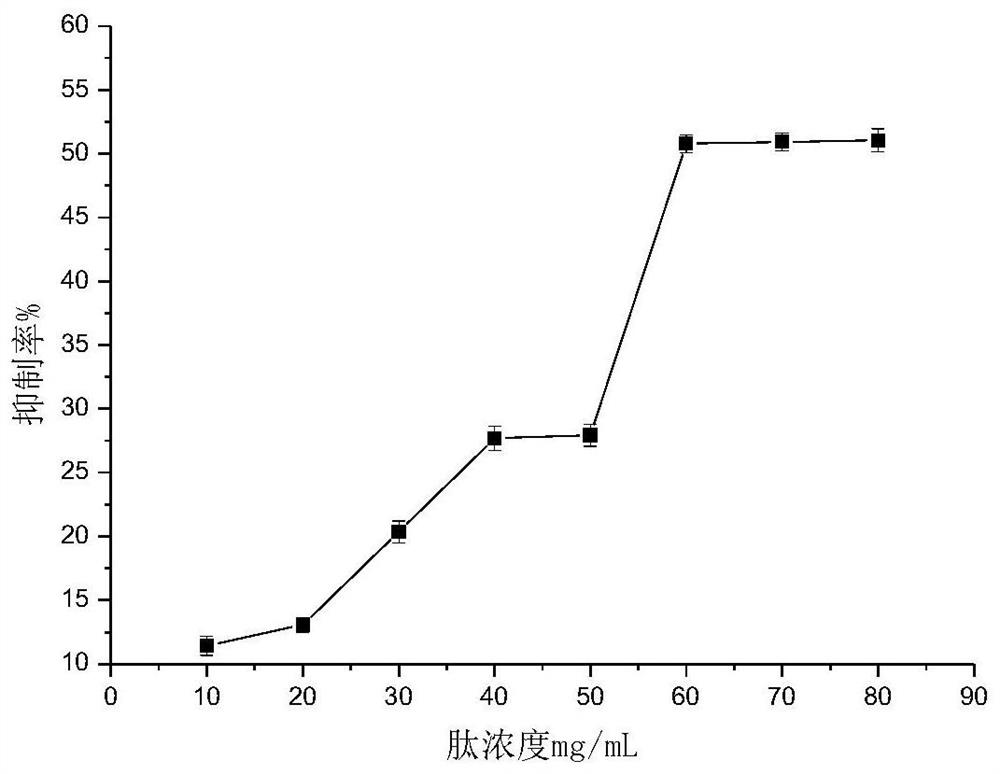

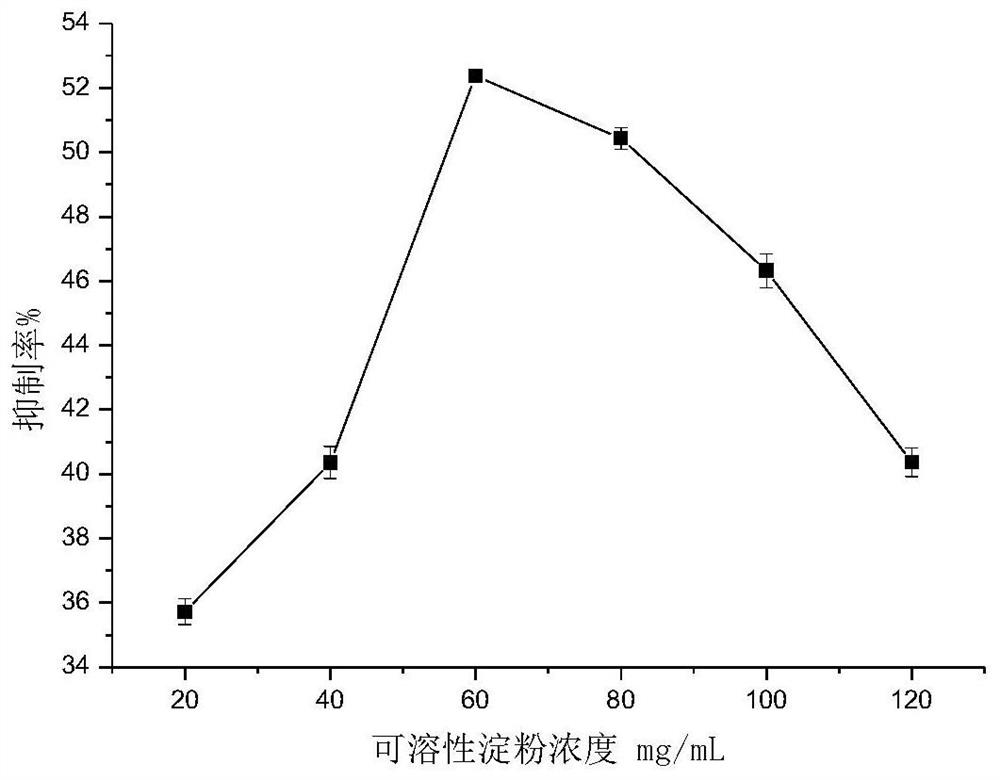

[0037] A preparation method of quinoa peptide, comprising the following preparation steps:

[0038] (1) Extraction of quinoa protein

[0039] Take 15g of quinoa grains, wash them with purified water for 3 times, dry them, add 50ml of petroleum ether at 90°C and grind them evenly, let them soak for 3 hours, evaporate the petroleum ether, grind them into 80-mesh fine powder, and obtain defatted quinoa flour; Then use α-amylase to hydrolyze to remove the starch in quinoa flour, wherein, the ratio of solid to liquid during α-amylase hydrolysis is 1:6 (w / v), pH is 8, enzyme amount is 200u / g, enzyme The hydrolysis temperature was 60°C, the enzymatic hydrolysis time was 150min, and the extraction rate of quinoa protein was 73.9%.

[0040] (2) Purification of quinoa protein

[0041] The quinoa protein was concentrated and purified by an ultrafiltration device with a 20KD membrane pore size, and the extraction rate of the obtained quinoa protein was 80.2%;

[0042] (3) Hydrolysis of...

Embodiment 2

[0112] A preparation method of quinoa peptide, comprising the following preparation steps:

[0113] (1) Extraction of quinoa protein

[0114] Take 15g of quinoa grains, wash them with purified water for 4 times, dry them, add 50ml of petroleum ether at 65°C and grind them evenly, let them soak for 3.5 hours, evaporate the petroleum ether, and grind them into a 60-mesh fine powder to obtain defatted quinoa flour; Then use α-amylase to hydrolyze to remove the starch in quinoa flour, wherein, the ratio of solid to liquid during α-amylase hydrolysis is 1:6 (w / v), pH is 8, enzyme amount is 200u / g, enzyme The hydrolysis temperature was 60°C, the enzymolysis time was 150min, and the extraction rate of quinoa protein was 74.0%.

[0115] (2) Purification of quinoa protein

[0116] The quinoa protein was concentrated and purified by an ultrafiltration device with a membrane pore size of 20KD, and the extraction rate of the obtained quinoa protein was 81.2%.

[0117] (3) Hydrolysis of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com