Supporting assembly with high adaptability

A support component and adaptable technology, which is applied in the direction of construction and building construction, can solve the problems of poor mechanical performance of fastening turnbuckle screws, heavy welding workload, complicated processing and manufacturing, and achieve economical fastening turnbuckles The screw and welding workload is small and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

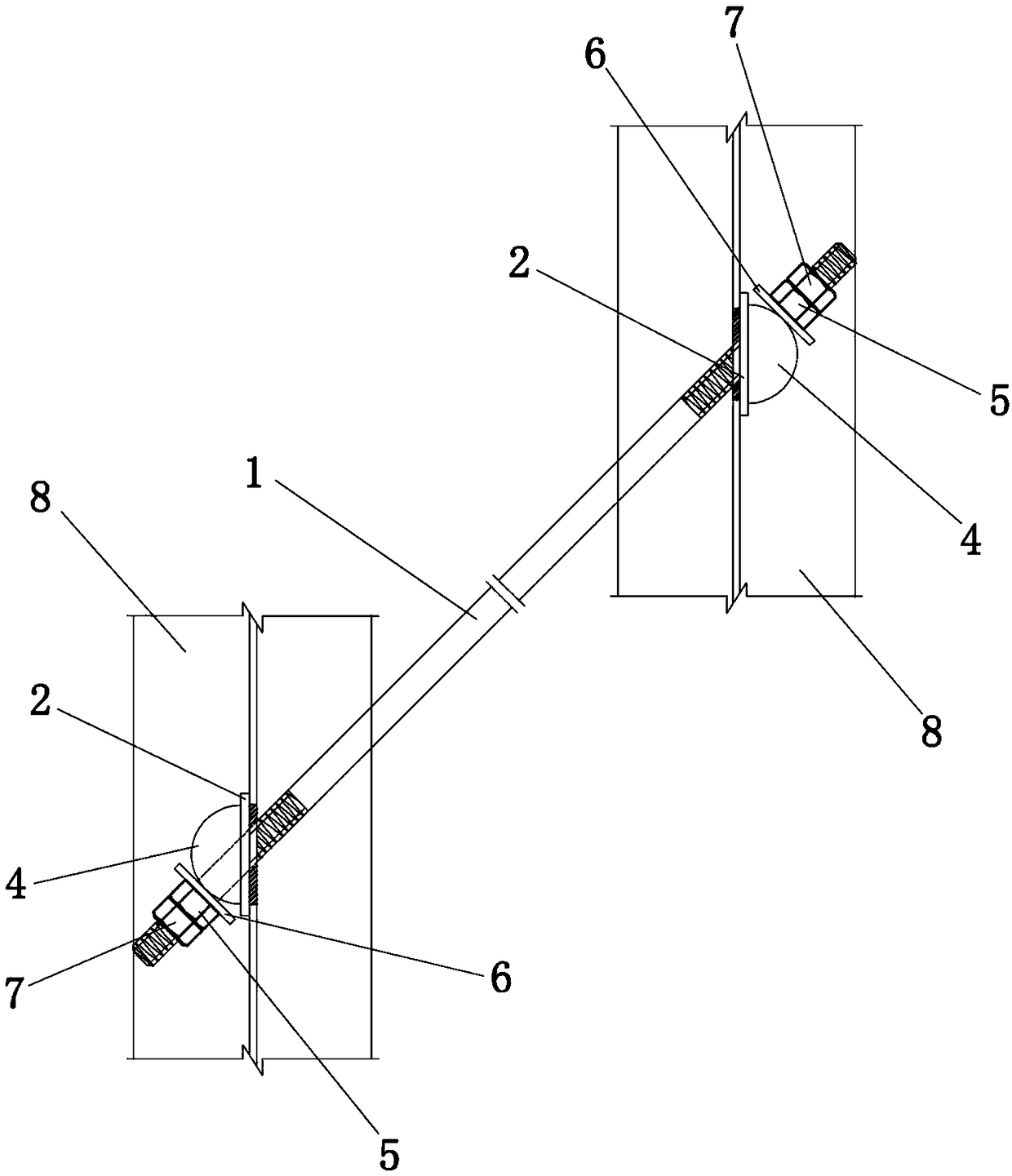

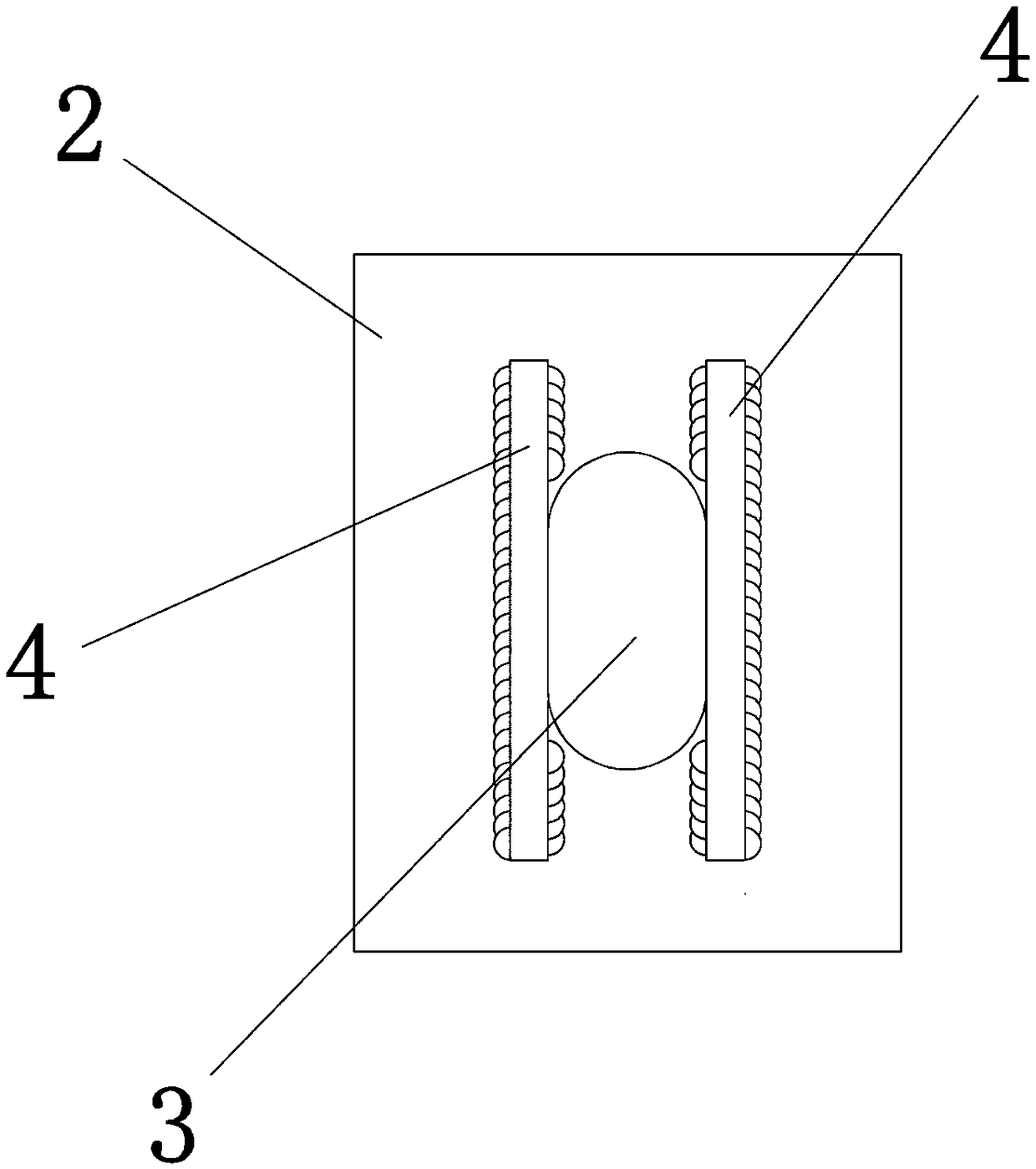

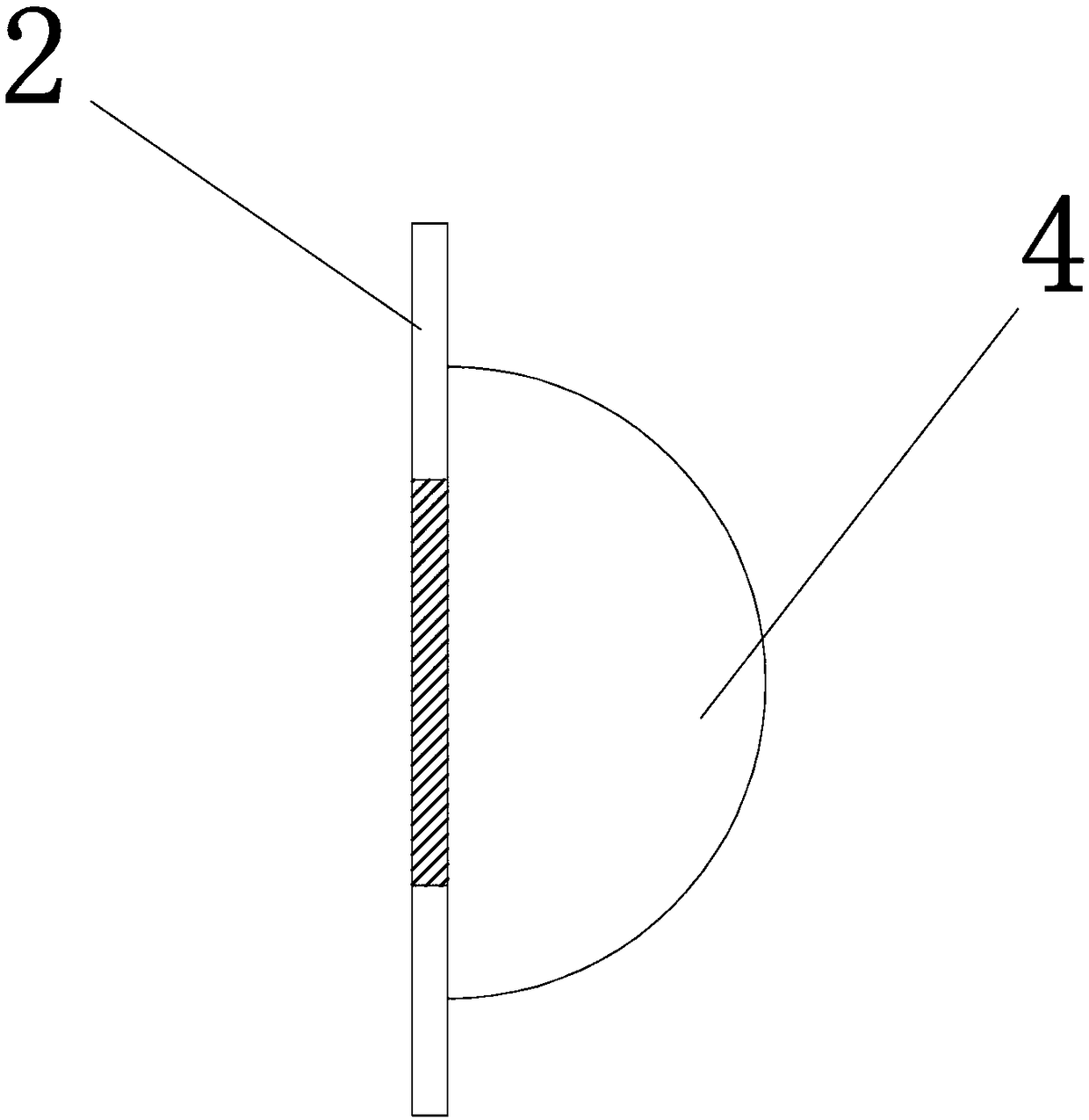

[0017] An adaptable support assembly such as figure 1 , figure 2 , image 3 As shown, including a support rod 1, the two ends of the support rod 1 are respectively threaded with a left support assembly and a right support assembly, and the structure of the right support assembly is symmetrical to that of the left support assembly; the left support assembly includes a reinforcement plate 2, a tight Fixing device 5, the reinforcing plate 2 is provided with oblong holes 3; the oblong holes 3 are pierced on the support rod 1; the reinforcing plate 2 is provided with a number of pads 4 arranged at intervals; the fastening device 5 is connected to the supporting rod 1, and the fastening device 5 is located on the outside of the spacer 4.

[0018] In this embodiment, the pad 4 is semicircular, and there are two pads 4, and the two pads 4 are evenly arranged on both sides of the oblong hole 3, and the force is uniform.

[0019] In this embodiment, the supporting rod 1 is pierced w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com