Underground device for reaming while drilling

A reamer and drilling-while-drilling technology, which is applied to drill bits, earthwork drilling, drilling equipment, etc., can solve problems such as low reaming efficiency, poor work safety, and high service costs of reamers, so as to ensure system stability and work High stability, the effect of preventing falling to the bottom of the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

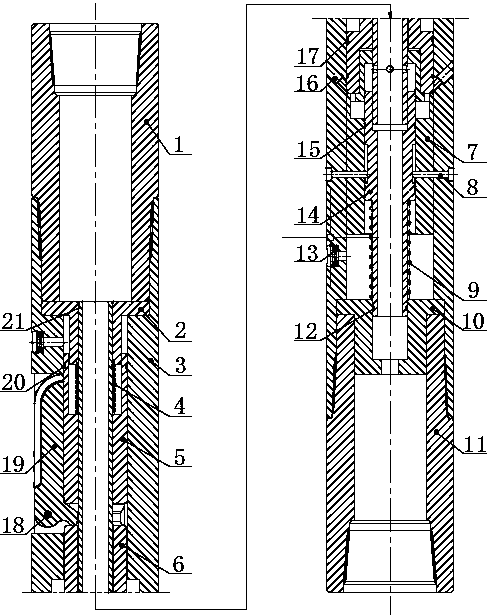

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] See attached figure 1 , a downhole reamer while drilling includes an upper joint 1, a body, and a lower joint 11. The upper joint 1 is connected to the upper end of the body through threads, and the lower end of the body is connected with a lower joint 11 through threads. The upper end of the outer cylinder 3 and the lower end of the upper joint 1 An upper anti-drop ring 2 is installed between them, and a lower anti-drop ring 10 is installed between the lower end of the outer cylinder 3 and the upper end of the lower joint 11; the body includes an outer cylinder 3, an upper end spring 4, an upper piston 5, a lower piston a6, Lower piston b7, pin a8, lower end spring 9, lower anti-drop ring 10, O-ring a12, bypass valve 13, indexing mechanism 14, O-ring b15, nozzle 16, O-ring c17, pin b18 , knife wing 19, O-shaped seal ring d20 and central tube 21, on the central tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com