Test device and test method for platform formation performance under ultralow temperature

A sheet metal forming and testing device technology, applied in the direction of measuring devices, analyzing materials, strength properties, etc., can solve the problems of inability to obtain deformation information and mechanical properties of metal sheets, and achieve in-situ and dynamic real-time, accurate test data, and material parameters. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

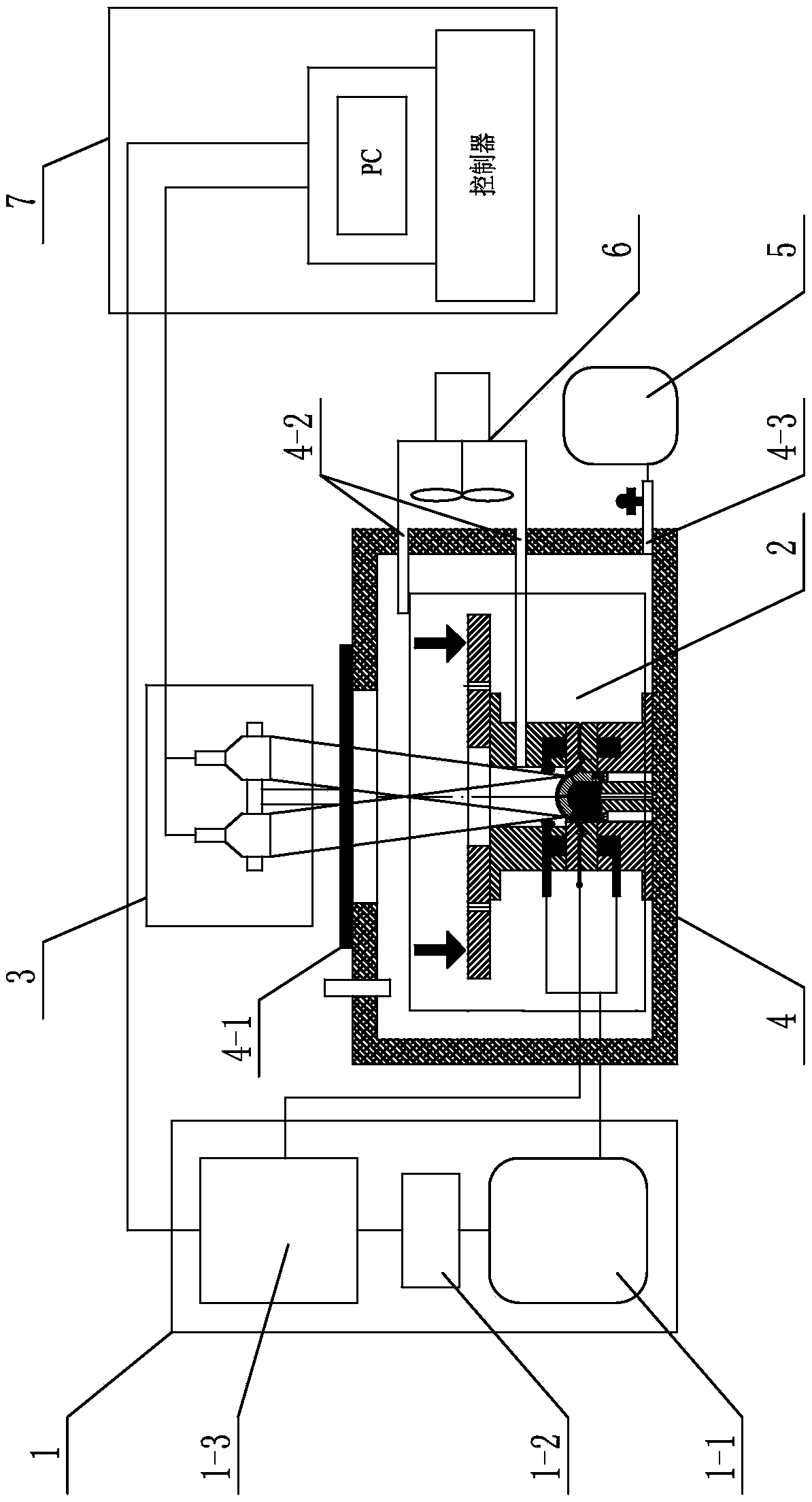

[0034] Specific implementation mode one: as figure 1 As shown: the test device for sheet metal formability described in this embodiment includes an ultra-low temperature cooling system 1, a deformation test system 2, an incubator 4, a coolant recovery device 5 and an exhaust device 6;

[0035] The deformation testing system 2 is arranged in the incubator 4; the ultra-low temperature cooling system 1, the coolant recovery device 5 and the exhaust device 6 are arranged outside the incubator 4;

[0036] The incubator 4 is provided with a transparent observation window 4-1, two exhaust holes 4-2, a liquid inlet hole and a liquid discharge hole 4-3; the transparent observation window 4-1 is used for monitoring the metal plate Deformation information under a complex stress state, the exhaust device 6 communicates with the casing of the incubator through an exhaust hole 4-2, communicates with the deformation testing system 2 through another exhaust hole 4-2, and The mist in the incu...

specific Embodiment approach 2

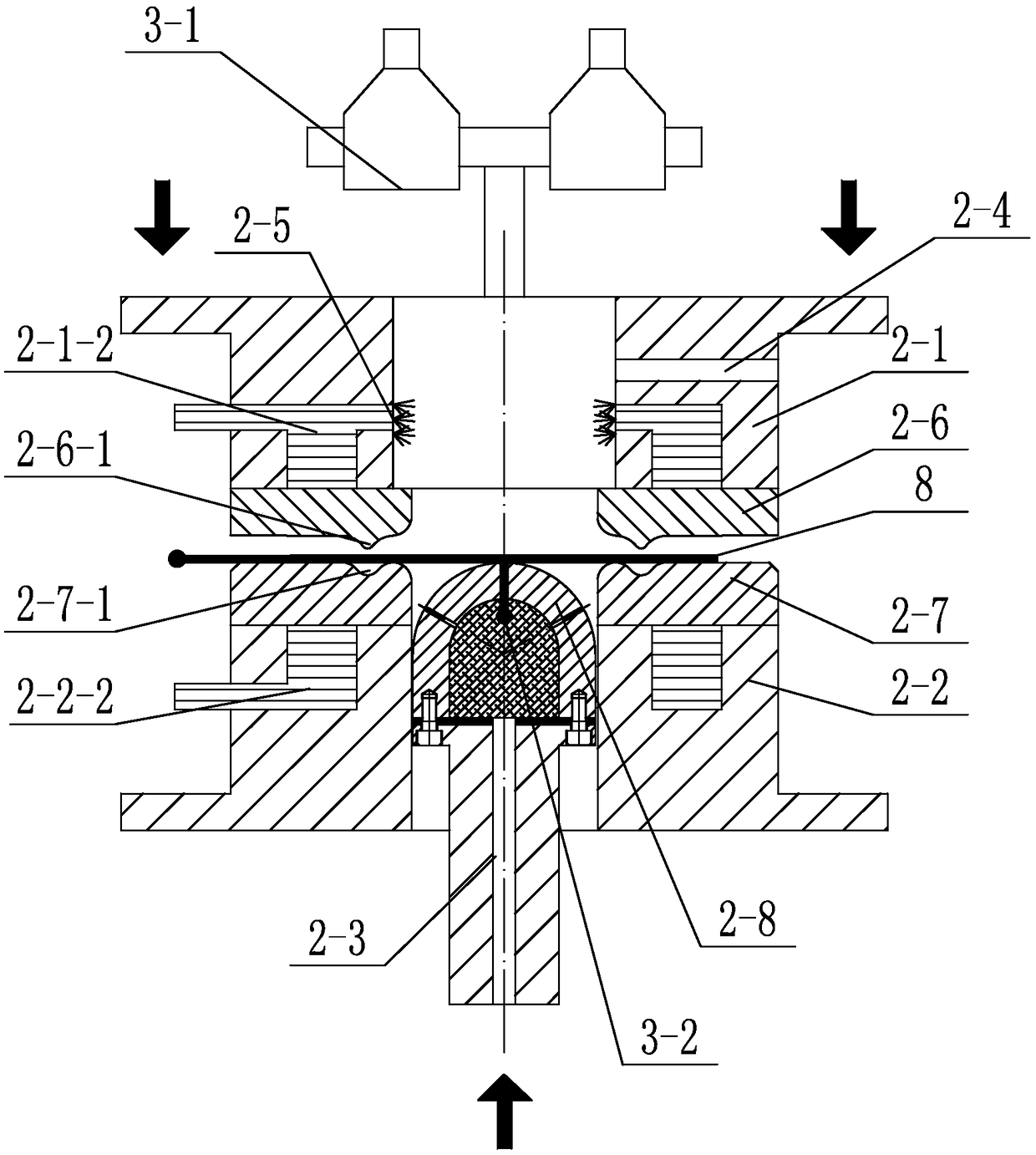

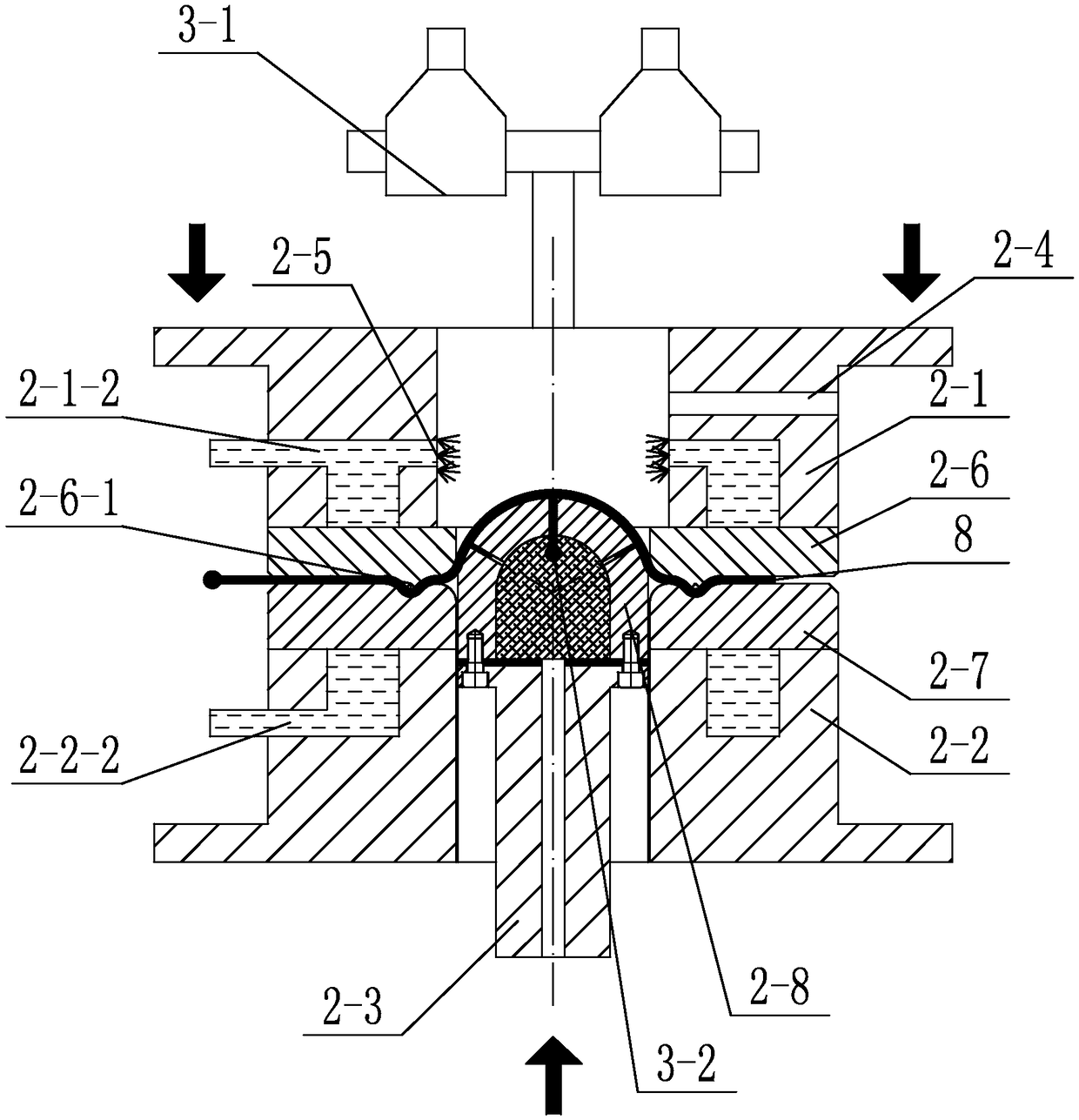

[0041] Specific implementation mode two: as Figure 1-7 As shown, the deformation testing system 2 described in this embodiment also includes an upper binder ring 2-6 and a lower binder ring 2-7; the upper binder ring 2-6 and the lower binder ring 2-7 are both It is a circular ring and is arranged coaxially with the upper and lower clamps; the upper binder ring 2-6 is located under the upper clamp 2-1, and the lower binder ring 2-7 is located under the lower clamp 2- 2, sheet metal 8 is installed between the upper blank holder 2-6 and the lower blank holder 2-7.

[0042] Other composition and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0043] Specific implementation mode three: as image 3 with 7 As shown: the lower surface of the upper binder ring 2-6 described in this embodiment has a raised portion 2-6-1, and the upper surface of the lower binder ring 2-7 has a groove 2-7-1, The raised portion 2-6-1 and the groove 2-7-1 are vertically opposite to each other, and the raised portion 2-6-1 coincides with the groove 2-7-1.

[0044] Other composition and connection methods are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com