Heating control detection equipment and detection control method of multistrand insulation self-heating wire

A technology for controlling detection and insulated wires, applied in measuring devices, measuring only voltage, measuring electrical variables, etc., can solve problems such as no precise control method for current, poor control of voltage difference, and high insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

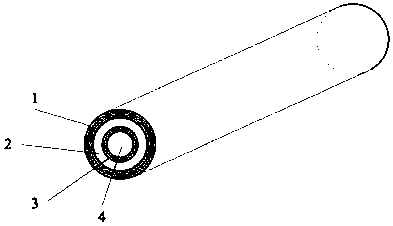

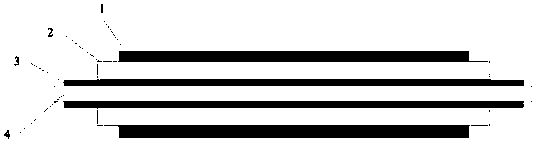

[0134] The multi-strand insulated self-made heating wire is composed of an outer conductor 1, a protective metal ring 2, an insulating heat-conducting ring 3 and an inner heating ring 4 from outside to inside. The two ends of the multi-strand insulated self-made heating wire are called A terminal and B terminal. Wire connecting end A 14 is set at the end, and wire connecting end B 15 is set at the B end, the wire connecting end A is at the self-made heating wire A end; the wire connecting end B is at the self-made heating wire B end. The connecting ends of the wires at both ends are connected to the same phase transmission line at both ends; a control system with the same structure is respectively set at the connecting ends of the two wires to control the power transmission, heating and self-inspection of the wires.

[0135] See attached figure 1 , 2 .

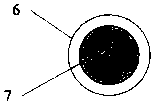

[0136] When the inner heating ring 4 of the multi-strand self-made heating wire is an insulating structure or an insulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com