Motor housing and motor

A technology for motor shells and casings, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., which can solve the problems of thinning spiral channel wall thickness, decreased safety factor, water leakage, etc., to reduce processing costs, Improve stability and avoid structural impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

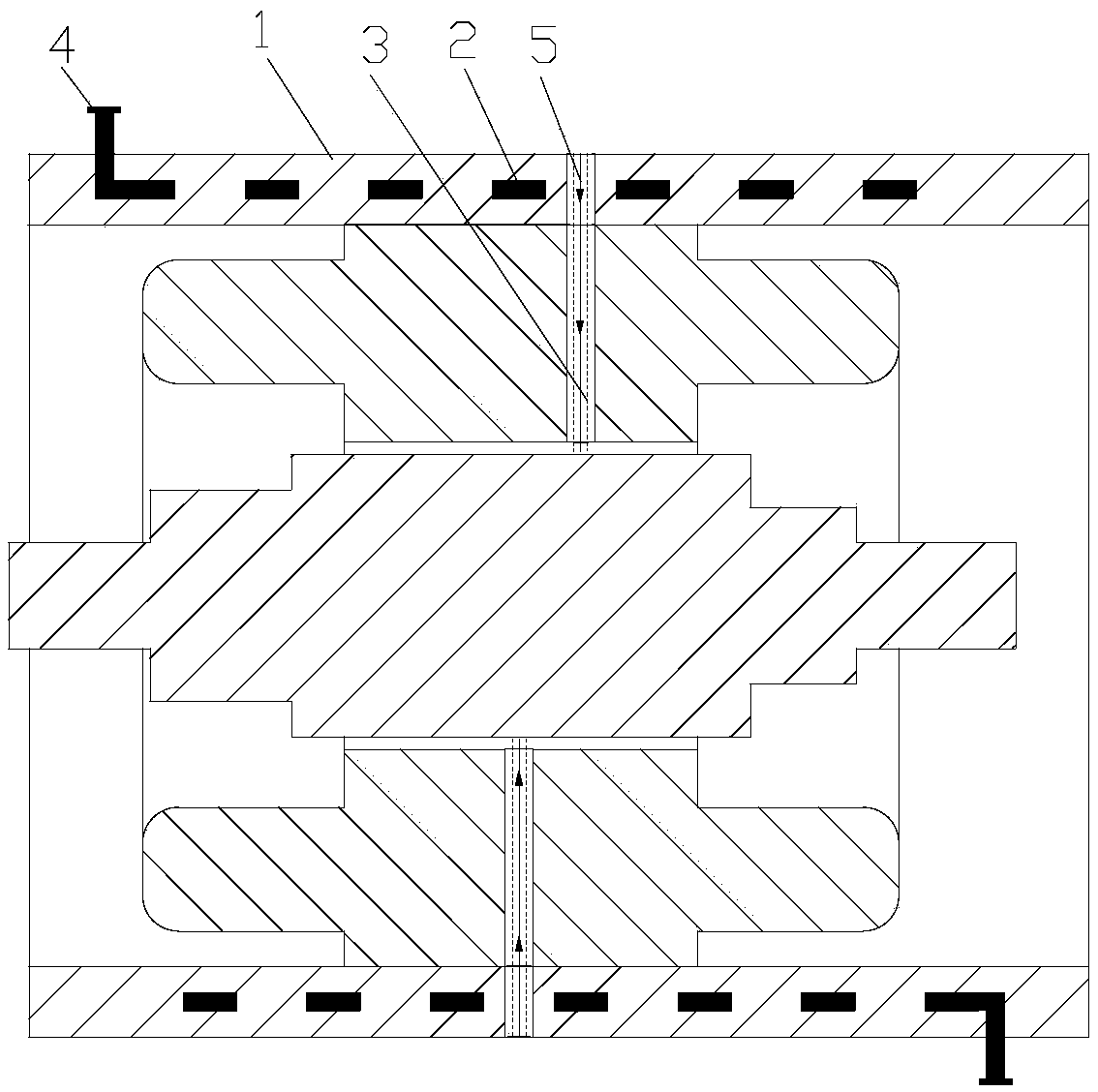

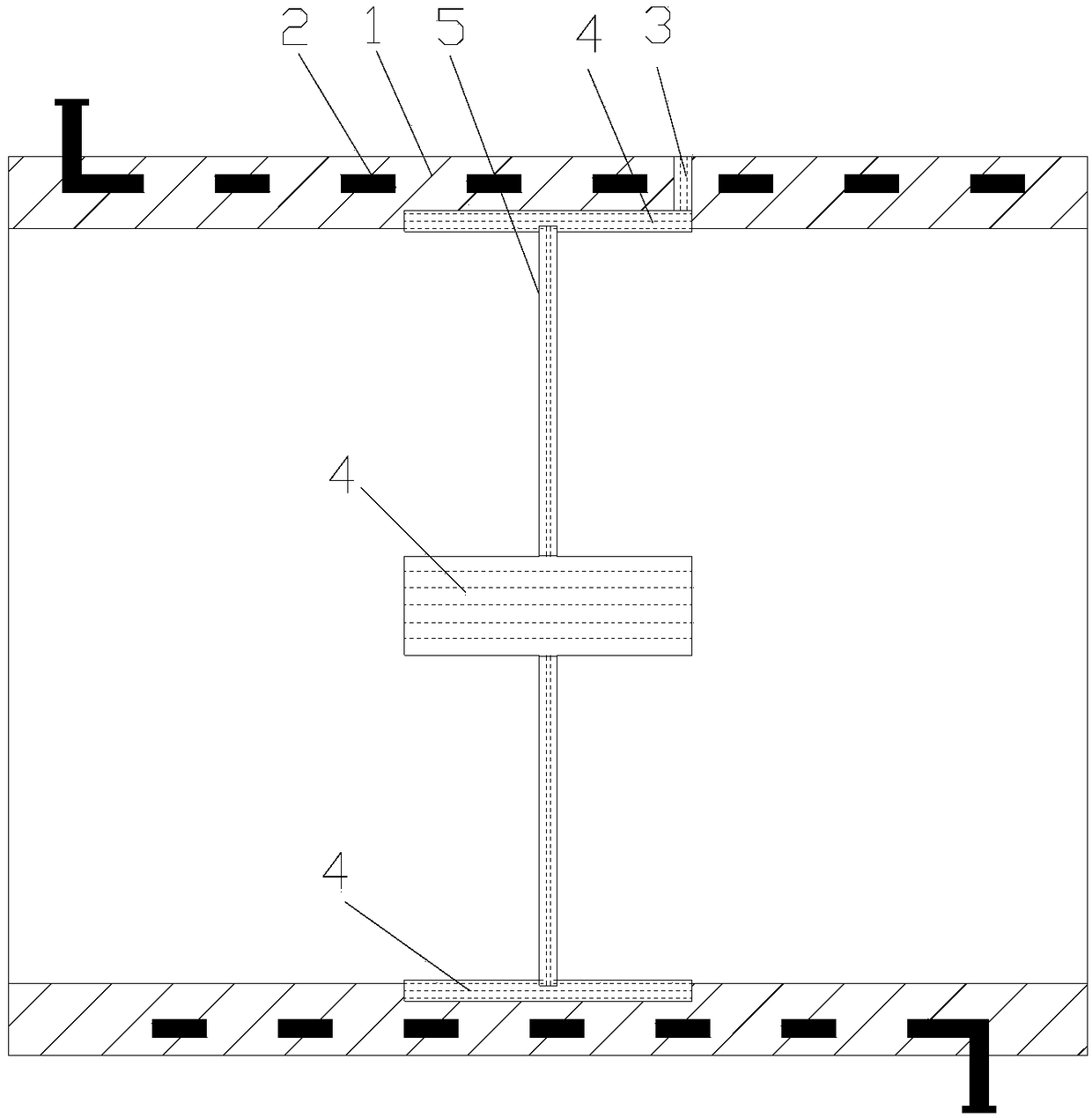

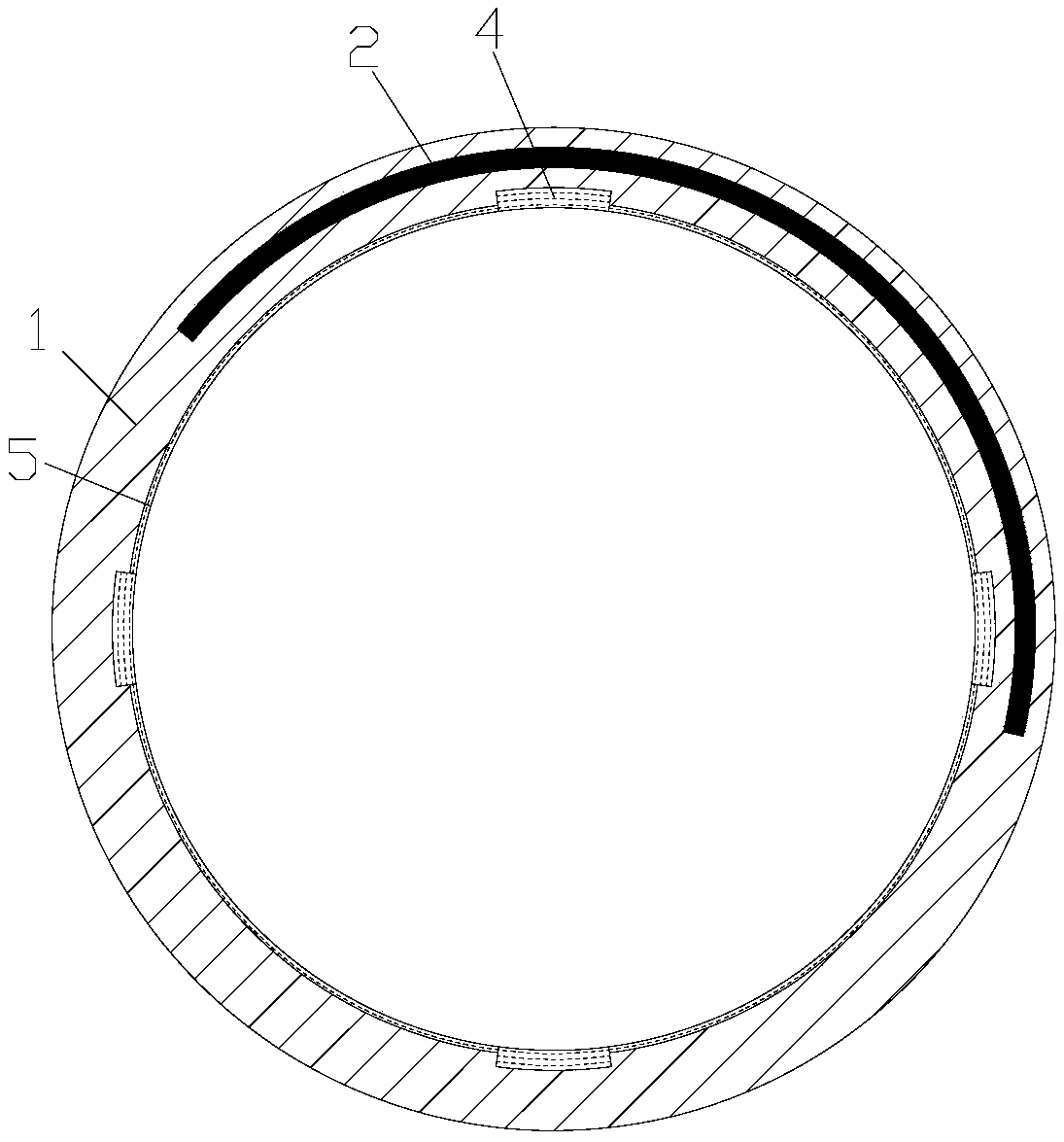

[0023] see in conjunction Figure 2 to Figure 4 As shown, according to the embodiment of the present invention, the motor casing includes a casing 1, and the casing 1 is provided with a spiral water channel 2, an air inlet 3 and a communication channel 4, and the spiral water channel 2 spirally extends along the axial direction of the casing 1, and further The air hole 3 is arranged on the outer surface of the casing 1 and extends radially of the casing 1 . The communication channel 4 is arranged on the inner peripheral side of the spiral water channel 2 and communicates with the air inlet 3 .

[0024] By setting the air intake channel on the casing 1 as a combination of the air intake hole 3 and the communication channel 4, and setting the communication channel 4 on the radial inner side of the spiral water channel 2, the airflow can be conveniently delivered to the The communication channel 4, since the communication channel 4 is arranged on the radial inner side of the spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com