Defoaming composition

A composition and defoaming technology, applied in the direction of liquid degassing, foam dispersion/prevention, chemical instruments and methods, etc., can solve the problems that the removal of internal bubbles cannot meet the production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 84 parts of 26# white oil, 5 parts of hydrophobic white carbon black (specific surface area 200m2 / g, chlorosilane hydrophobic treatment, hydrophobic value M= 70%) and 5 parts of lauryl polyoxyethylene (10) ether, keep the temperature at 80 ° C, stir at 1000 rpm for 4 hours, and turn on the emulsification circulation pump while stirring Circulation, so that the particle size distribution of hydrophobic particles in the carrier oil reaches 900nm; then add 1 part of SS-2, keep the above speed, and further stir and circulate for 1h; the temperature drops to 50 ° C, turn off the circulation pump, reduce the speed to 300rpm, add 5 Parts of isooctyl alcohol polyoxyethylene (8) ether, stirred for 10 minutes, the patented defoaming composition DA1 was obtained.

Embodiment 2

[0048] Add 75.5 parts of alkylbenzene, 9 parts of hydrophobic white carbon black (specific surface area 100m 2 / g, simethicone hydrophobic treatment, hydrophobic value M= 60%) and 9 parts of NP-10, keep the temperature at 140°C, stir at 2800rpm for 0.5h, while stirring, turn on the emulsification circulation pump to circulate, so that the hydrophobic The particle size distribution of the particles in the carrier oil reaches 600nm; then add 4.5 parts of SS-1, keep the above speed, further stir and circulate for 0.6h; the temperature drops to 60°C, turn off the circulation pump, reduce the speed to 500rpm, add 2 parts of octyl Phenol polyoxyethylene (10) ether, stirred for 30 minutes to obtain the patented defoaming composition DA2.

Embodiment 3

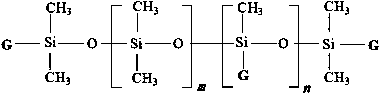

[0050] Add 89.8 parts of naphthenic oil, 1.5 parts of hydrophobic white carbon black (specific surface area 380m 2 / g, silazane hydrophobic treatment, hydrophobic value M= 65%) and 2.5 parts of D4425 (provided by AkzoNobel) and 3 parts of wetting agent Silwet-4, keep the temperature at 100 ° C, stir at 2500 rpm for 2.5 hours, While stirring, turn on the circulation of the emulsification circulation pump, so that the particle size distribution of the hydrophobic particles in the carrier oil reaches 800nm; then add 0.2 parts of SS-3, keep the above speed, and further stir and circulate for 2 hours; the temperature drops to 40 ° C, close the circulation Pump, reduce the rotation speed to 800rpm, add 3 parts of oleic acid polyoxyethylene (10) polyoxypropylene (2) ether, stir for 20 minutes, and obtain the patented defoaming composition DA3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com