Premixing mechanism for food processing

A technology for food processing and mixing barrels, which is used in mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve problems such as the influence of jam filling operations, the influence of jam mixing, and the long consumption of time, so as to avoid deterioration. Corruption, improve its own quality, improve the effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

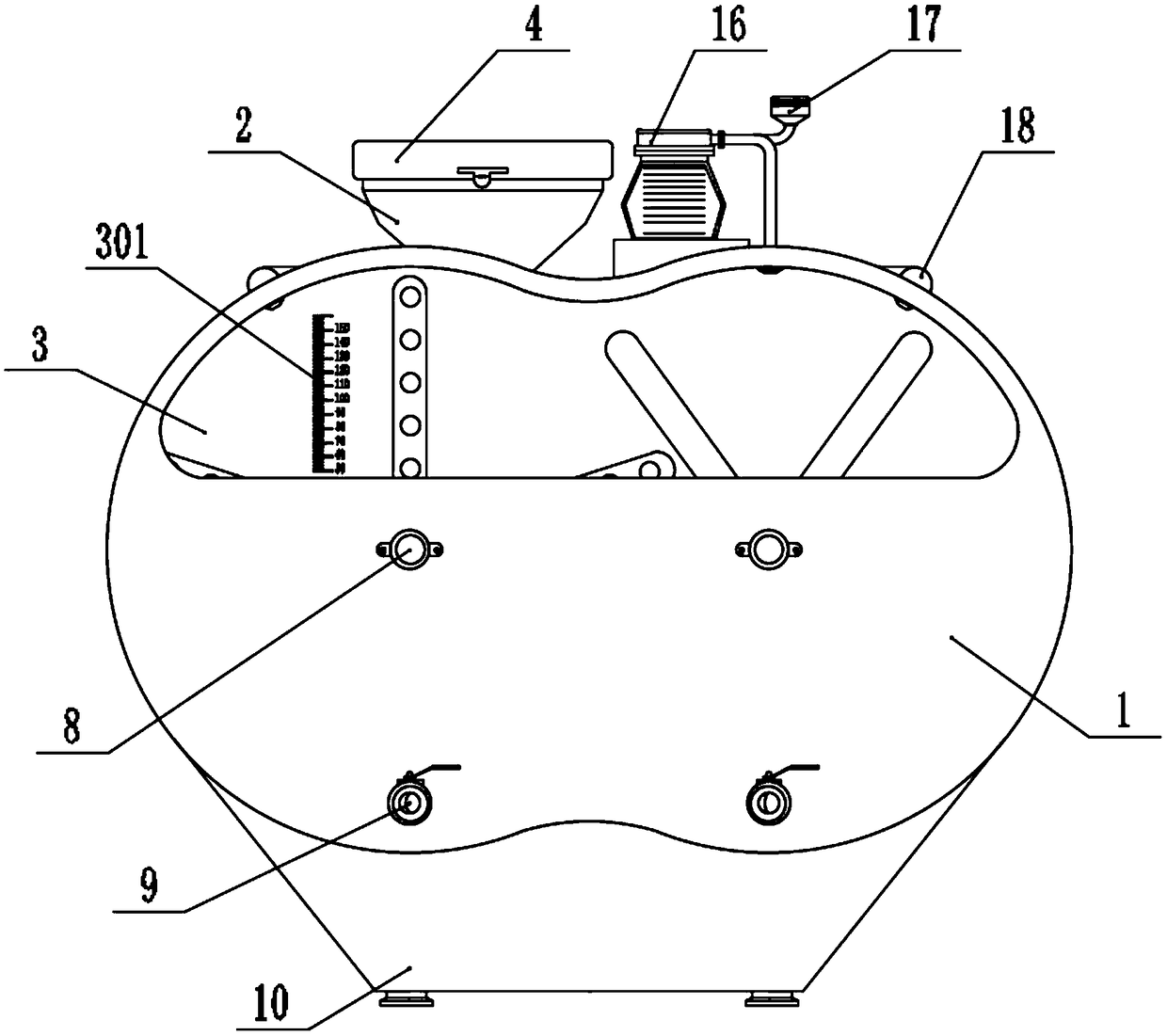

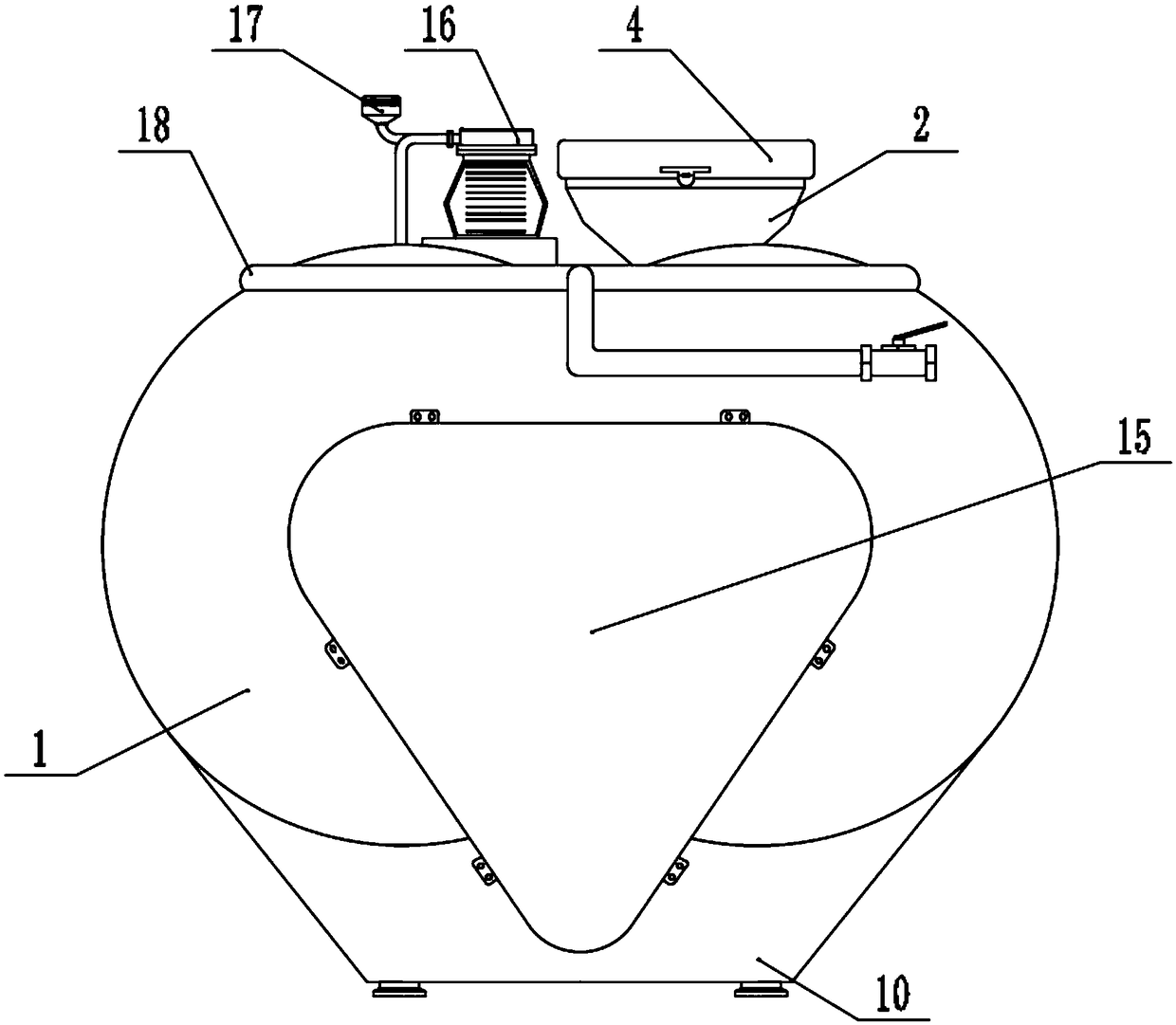

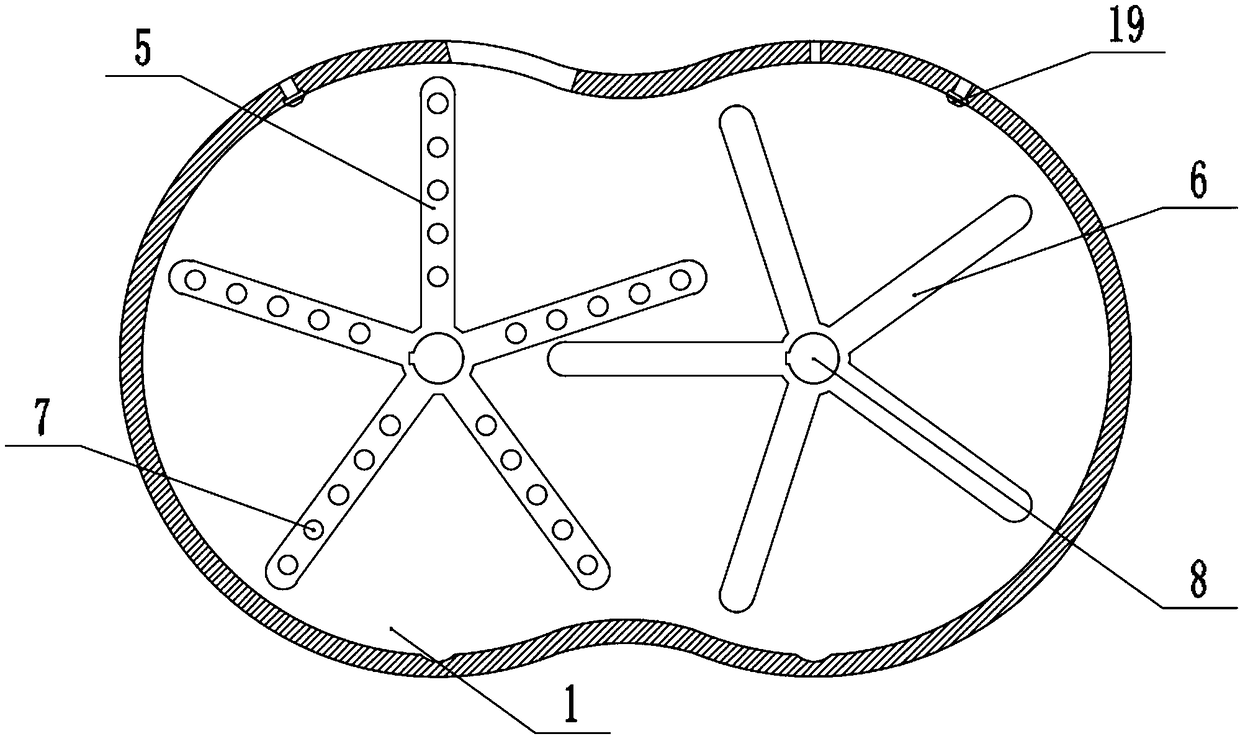

[0036] as attached figure 1 to attach Figure 9 Shown:

[0037]The invention provides a pre-mixing mechanism for food processing, comprising a mixing tank 1, a feeding funnel 2, a glass plate 3, a scale 301, a sealing cover 4, a sealing ring 401, a left mixing blade 5, and a right mixing blade 6 , stirring rod 7, rotating shaft 8, discharge valve 9, base 10, driven wheel 11, driving wheel 12, transmission belt 13, motor 14, protective cover 15, air pump 16, air filter cartridge 17, filter element 1701, water pipe 18, nozzle 19 and water valve 20; the inside of the mixing tank 1 is a hollow structure, and a feeding funnel 2 is installed on the top of the mixing tank 1, and the feeding funnel 2 communicates with the inside of the mixing tank 1; the sealing cover 4 is installed At the top of the feed funnel 2, and the bottom of the sealing cover 4 is attached to the top end surface of the feed funnel 2; the left mixing blade 5 and the right mixing blade 6 are respectively locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com