A mold structure and its manufacturing process

A production process and mold technology, applied in the field of mold structure and its production process, can solve the problems of unstable sand core fixation, easy eccentric core, low yield, etc., to prevent defects in processing, improve strength and yield improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

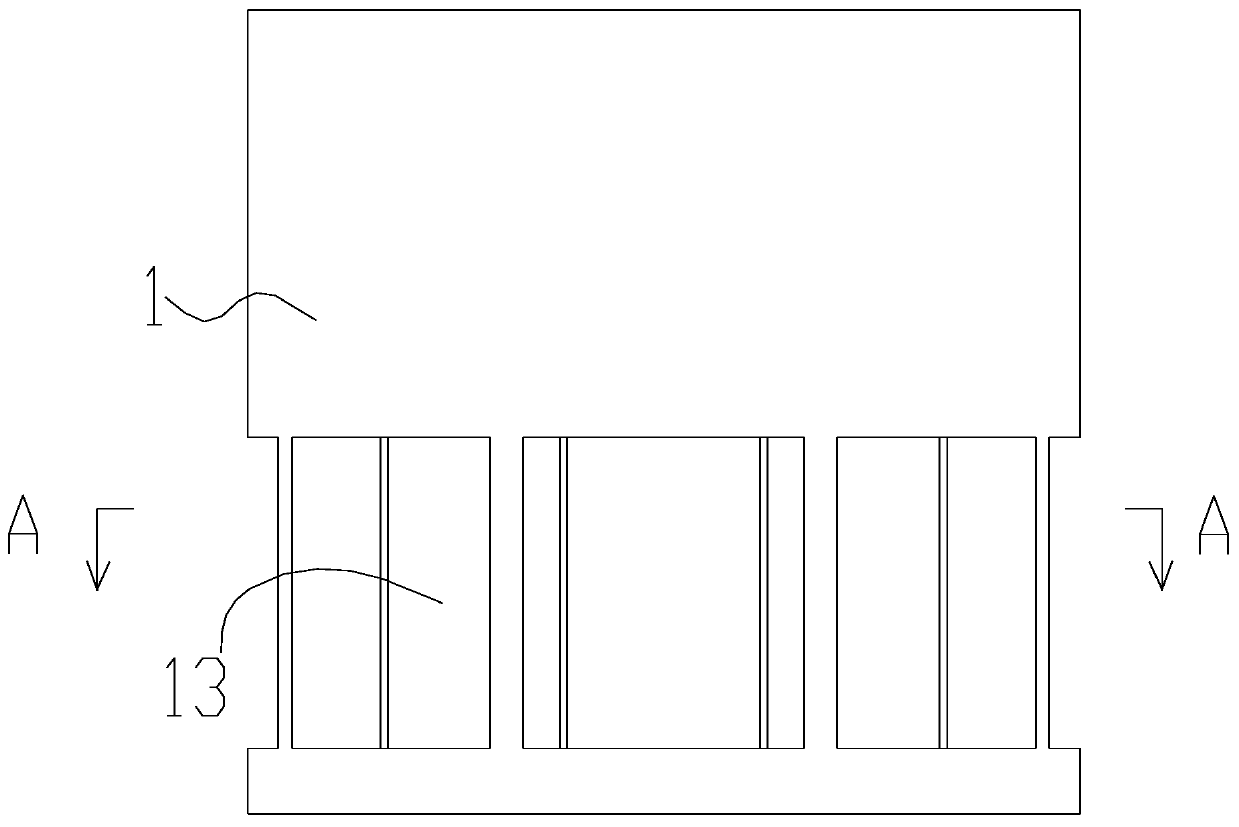

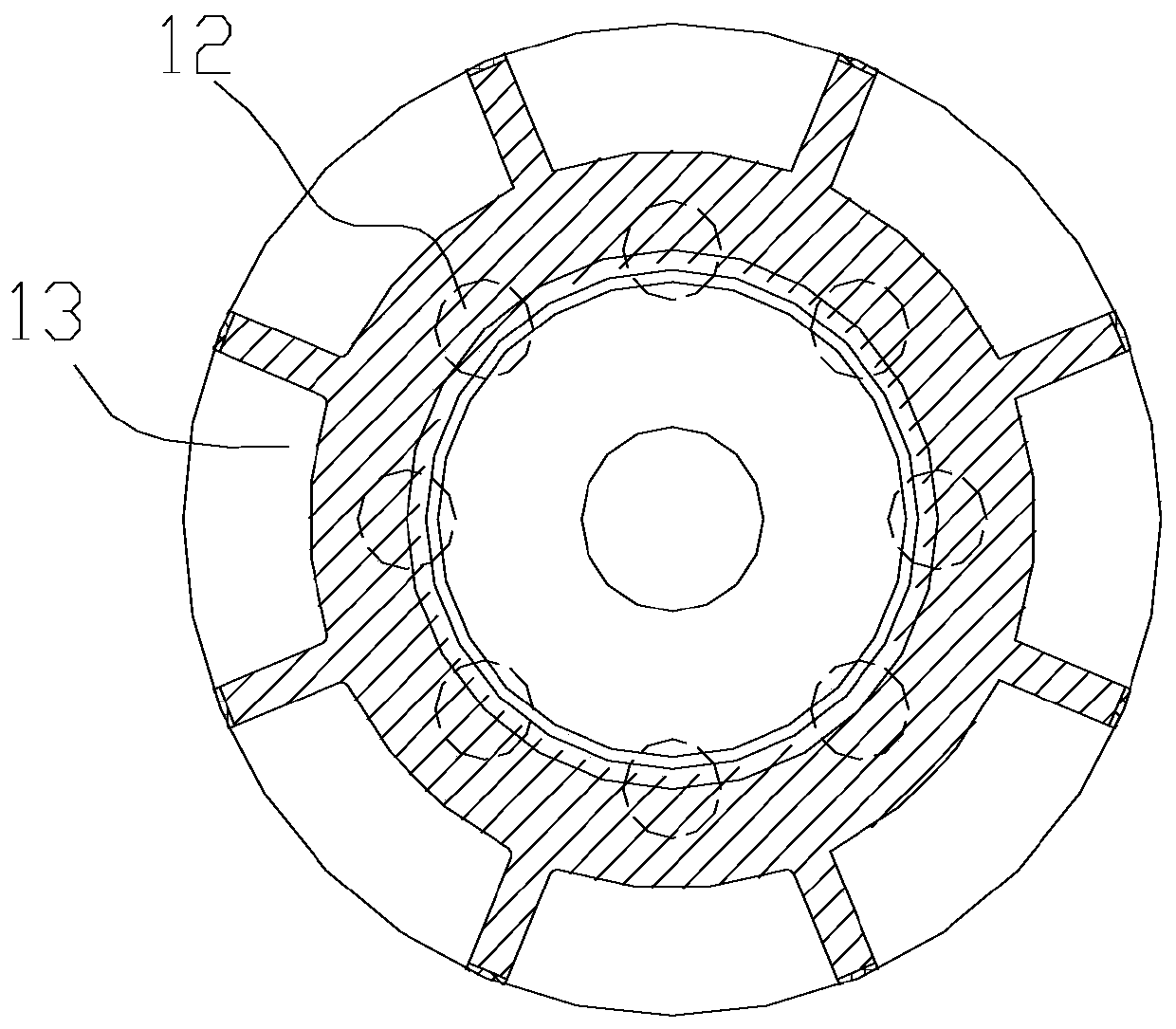

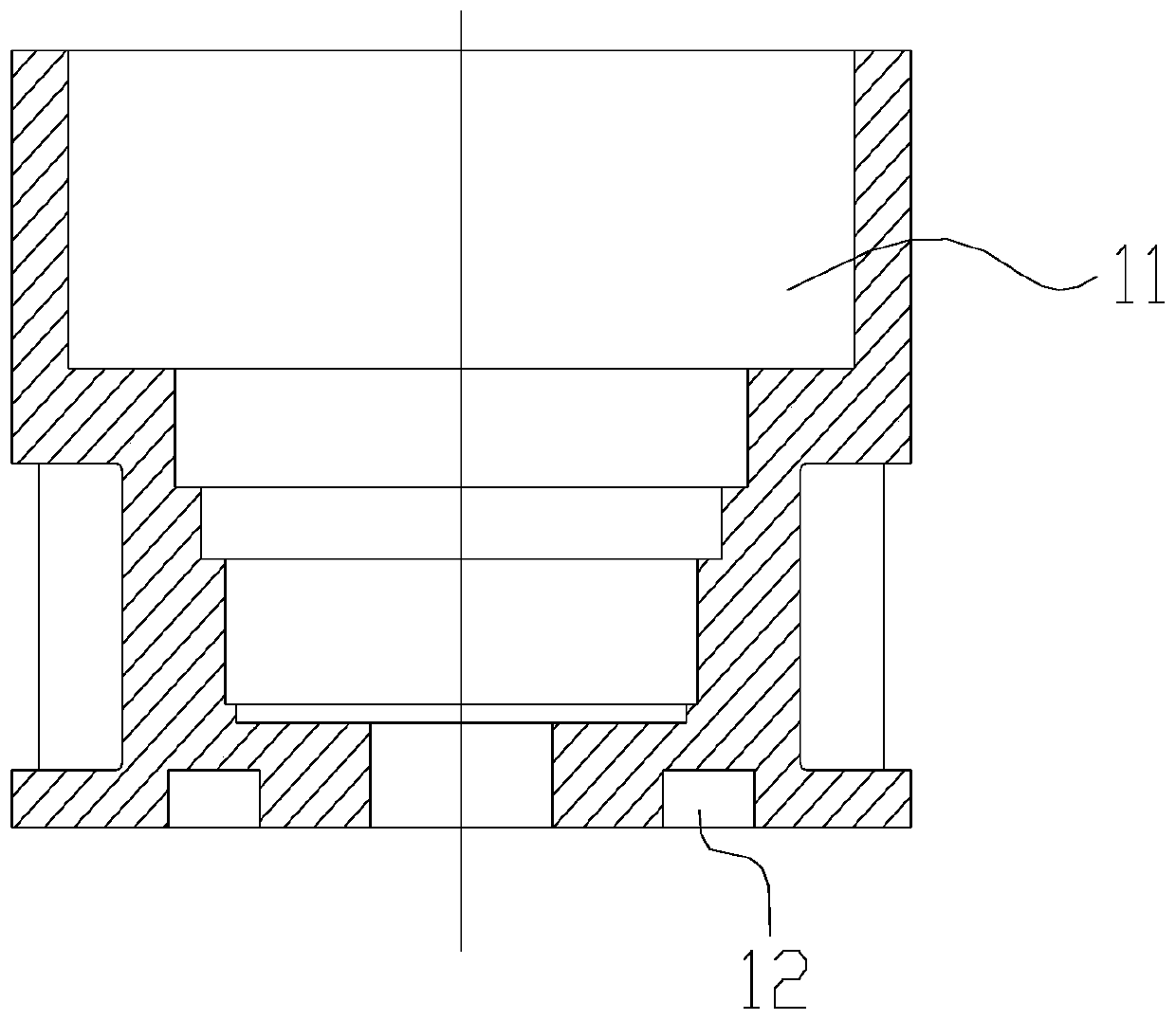

[0035] Such as Figure 1-7 , a mold structure, characterized in that: the main body of the casting 1 is a centrally symmetrical structure, the center of the casting 1 has a stepped through hole 11, the bottom of the casting 1 has a plurality of first grooves 12, and the side wall of the casting 1 near the bottom has a second The groove 13, the diameter of the stepped through hole 11 at the end away from the bottom of the casting 1 is larger than the diameter of the end of the casting 1 near the bottom;

[0036] The mold structure includes an upper box 2 and a lower box 3, the parting surfaces of the upper box 2 and the lower box 3 are arranged along the top surface of the second groove 13 of the casting 1, and the mold structure includes a stepped through hole 11 with the casting 1 The first sand core 4 whose shape matches, the lower box 3 has the second sand core 5 that matches the shape of the second groove 13, the side of the cavity inside the upper box 2 matches the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com