Robot, robot-based trash auto-recycling method and device and storage medium

An automatic recycling and robotic technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of waste of resources, inability to meet the requirements of urban waste recycling, and error-prone, and achieve the effect of avoiding low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a robot for automatically collecting garbage.

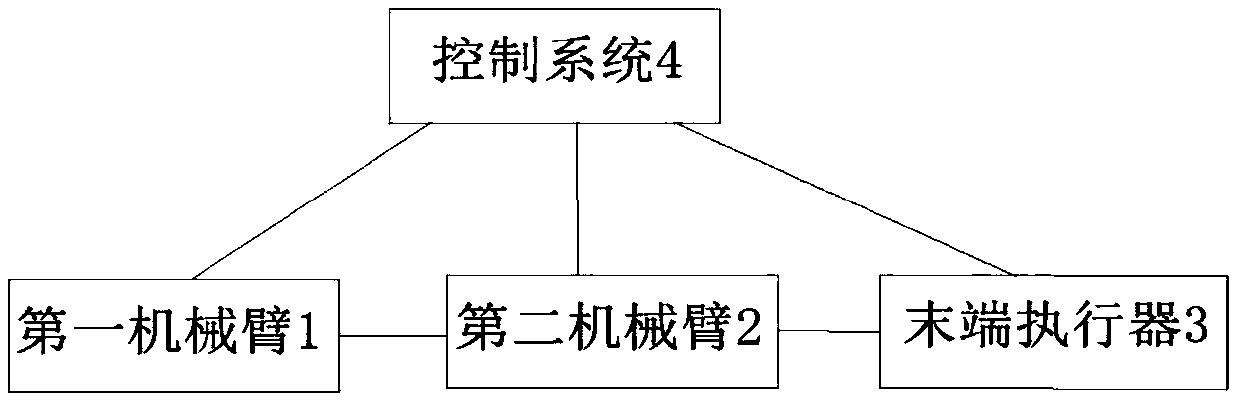

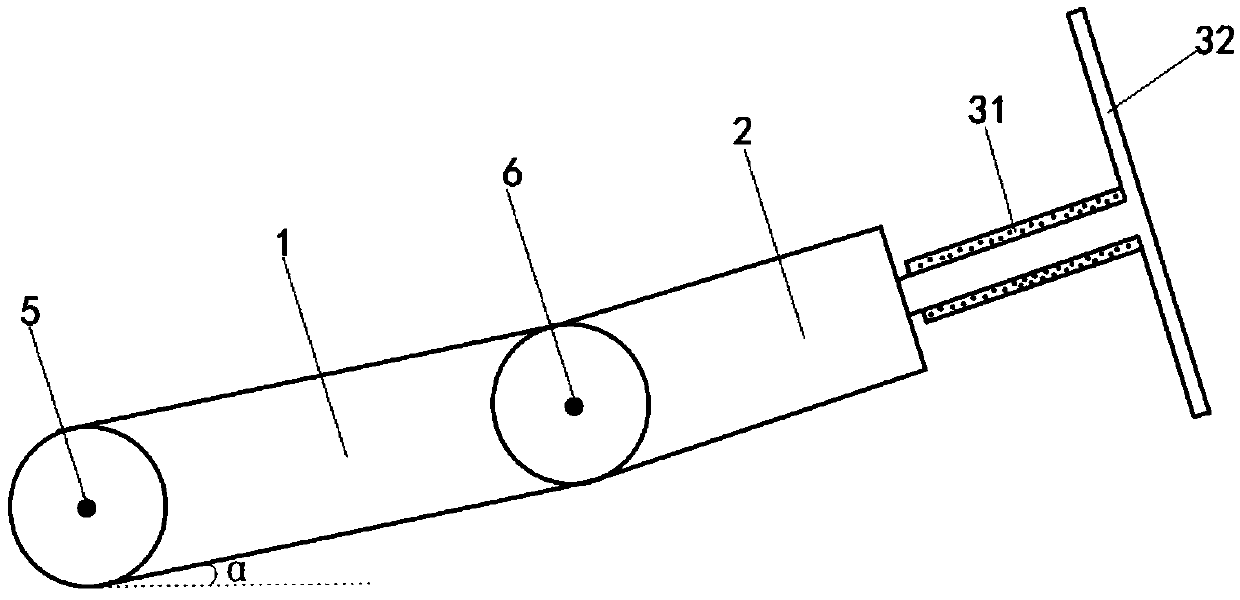

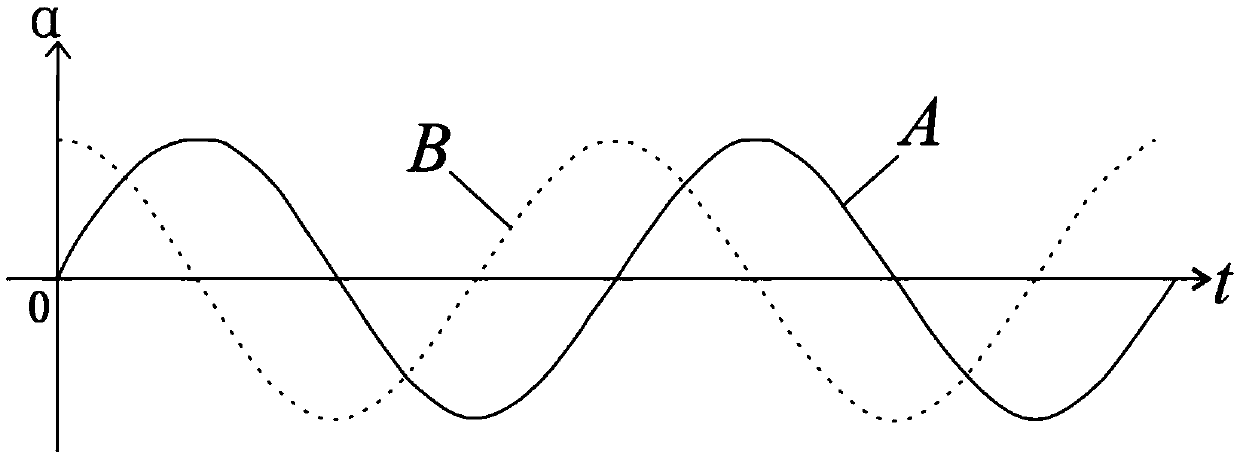

[0029] Please see figure 1 , figure 2 as well as image 3 , the robot includes: the robot is provided with a main body, a first mechanical arm 1 , a second mechanical arm 2 and an end effector 3 . The first mechanical arm 1 is connected to the main body through the movement axis of the shoulder joint 5 , and the first mechanical arm 1 swings around the movement axis of the shoulder joint 5 periodically left and right. The second mechanical arm 2 is connected to the first mechanical arm through the connecting shaft of the elbow joint 6 , and the end effector 3 is arranged at the end of the second mechanical arm 2 . The second mechanical arm 2 is free to rotate around the connection axis of the elbow joint 6 so as to drive the end effector 3 to pick up and place the target garbage.

[0030] In one of the examples, as Figure 4 As shown, the end effector 3 is a T-shaped gripper, and the T-shaped...

Embodiment 2

[0038] This embodiment provides a method for the robot to automatically recycle garbage, please refer to Figure 5 ,details as follows:

[0039] Step S201, acquiring images of the garbage on the conveyor captured by the visual device, wherein the conveyor is set at the entrance of the garbage incineration site, and is used to send the garbage into the incineration port;

[0040] Step S202, segmenting and identifying the garbage image through a neural network to obtain a classification result of the garbage image;

[0041] Step S203, according to the classification result, the control robot acquires the target garbage, and puts the target garbage into the recycling and sorting mechanism.

[0042] Such as Figure 6 As shown, the robot automatic garbage recycling method provided in this embodiment is applied in the recycling scene of the garbage dump, and also includes a recycling and sorting mechanism 8 for loading purpose garbage A; a recycling and sorting mechanism 9 for loa...

Embodiment 3

[0050] This embodiment provides a method for automatically collecting garbage by a robot. This embodiment is based on the second embodiment, and an additional process is added. details as follows:

[0051] Please see Figure 7 , after the control robot acquires the target garbage, it also includes:

[0052] Step S301, obtaining the spectrum of the target garbage through the spectrum analysis instrument, and judging whether the target garbage is metal or recyclable material;

[0053] Step S302, if yes, then control the robot to put the target garbage into the recycling and sorting mechanism;

[0054] Step S303, if not, the robot is controlled to put the target garbage into the mechanism to be determined.

[0055] In this embodiment, the spectrum analysis instrument is arranged between the conveyor and the recycling and sorting mechanism, and is used to analyze the spectrum of the target garbage, and the spectrum analysis instrument is added to analyze the spectrum of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com