Novel process flow diagram for the production of benzene from reformate without a toluene column

A xylene and material flow technology, applied in the petroleum industry, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve problems such as stabilization towers not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention relates to changing the process flow of an aromatic compound fractionation complex.

[0051] In the remainder of this text, the notation "A8+" will be used generally to denote all aromatic compounds containing 8 or more carbon atoms. In the same way, "A9+" means all aromatic compounds containing more than 9 carbon atoms, and so on. Hydrocarbon compounds that do not contain aromatic rings are called "aliphatic".

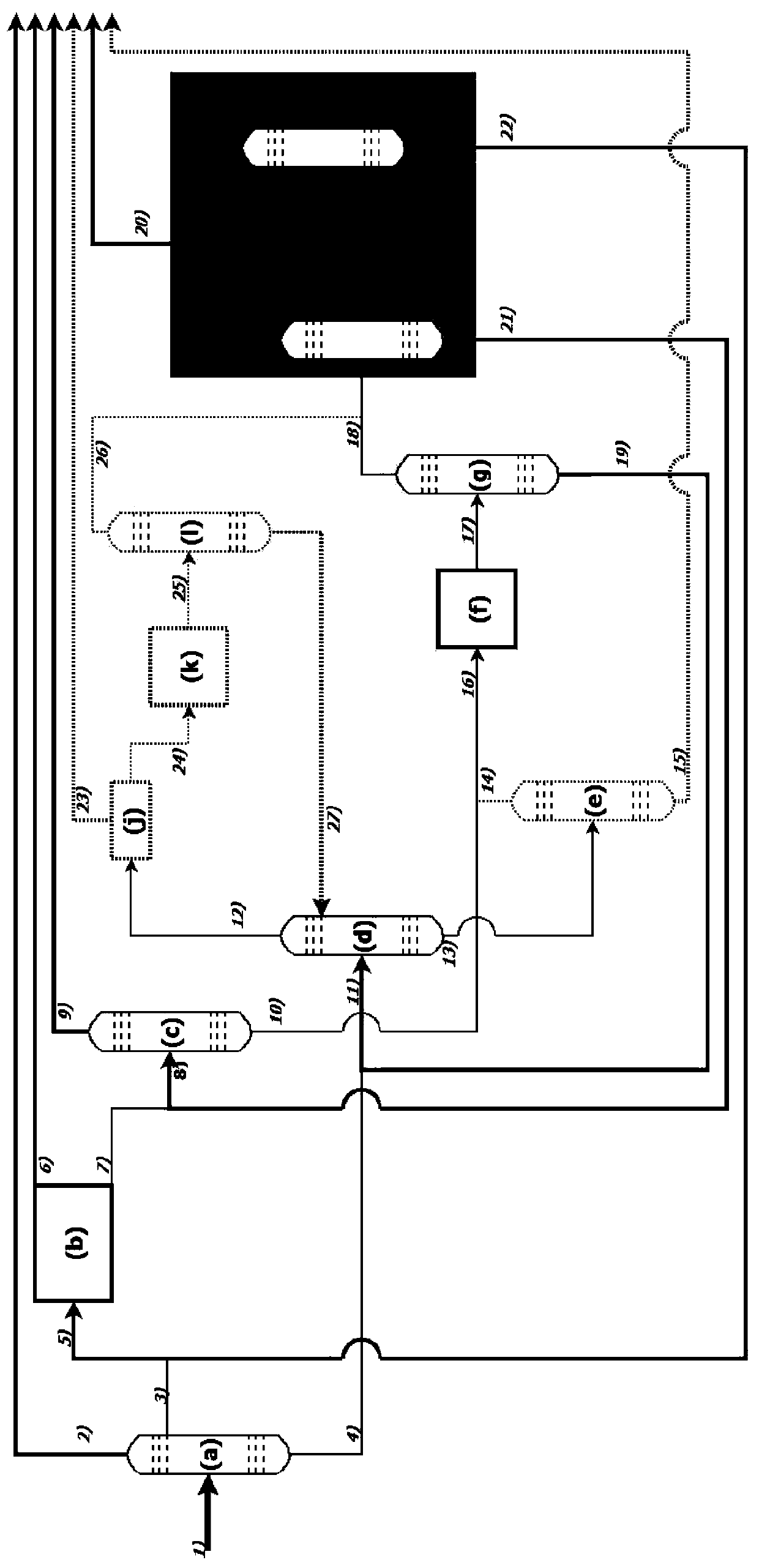

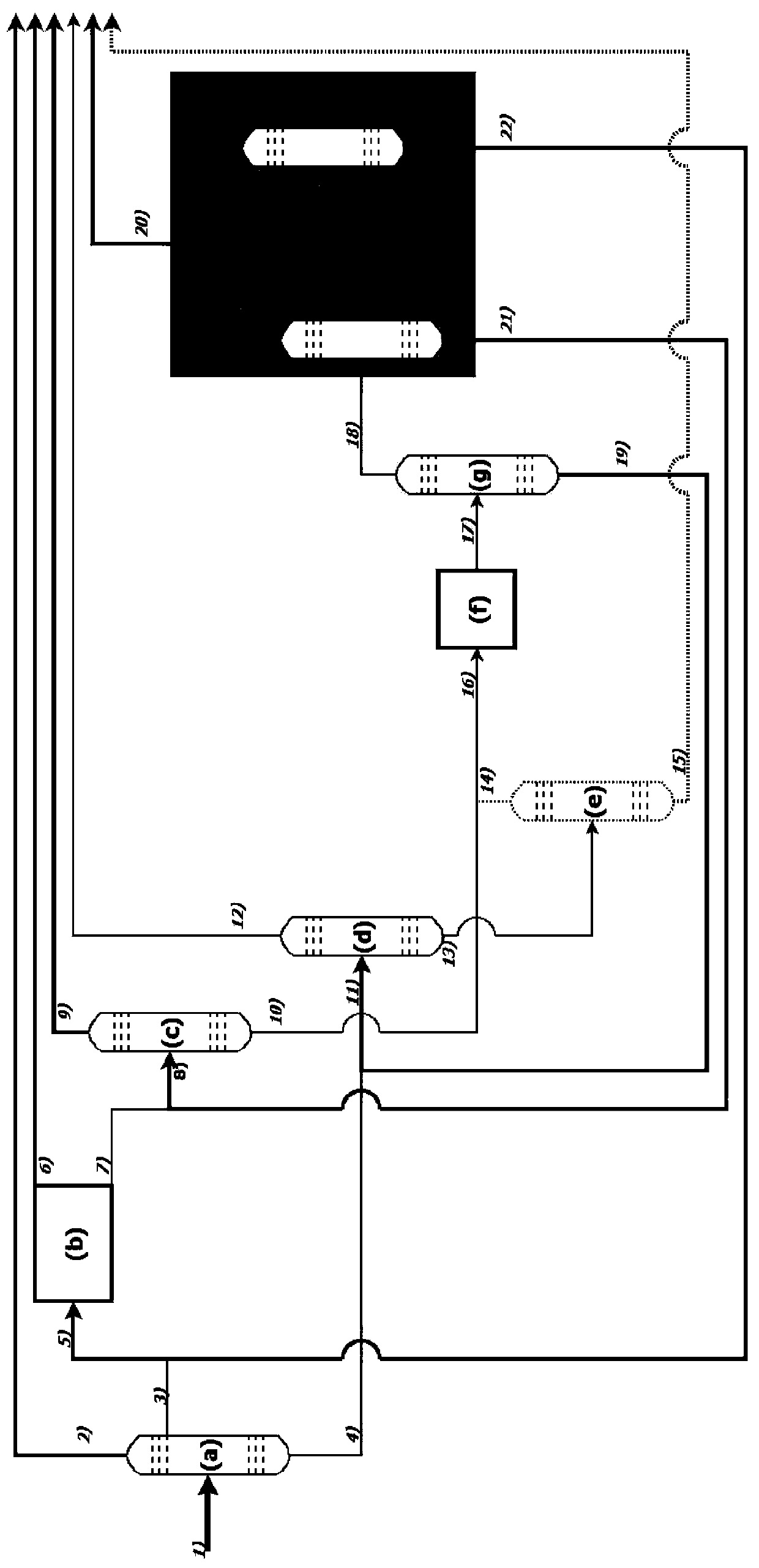

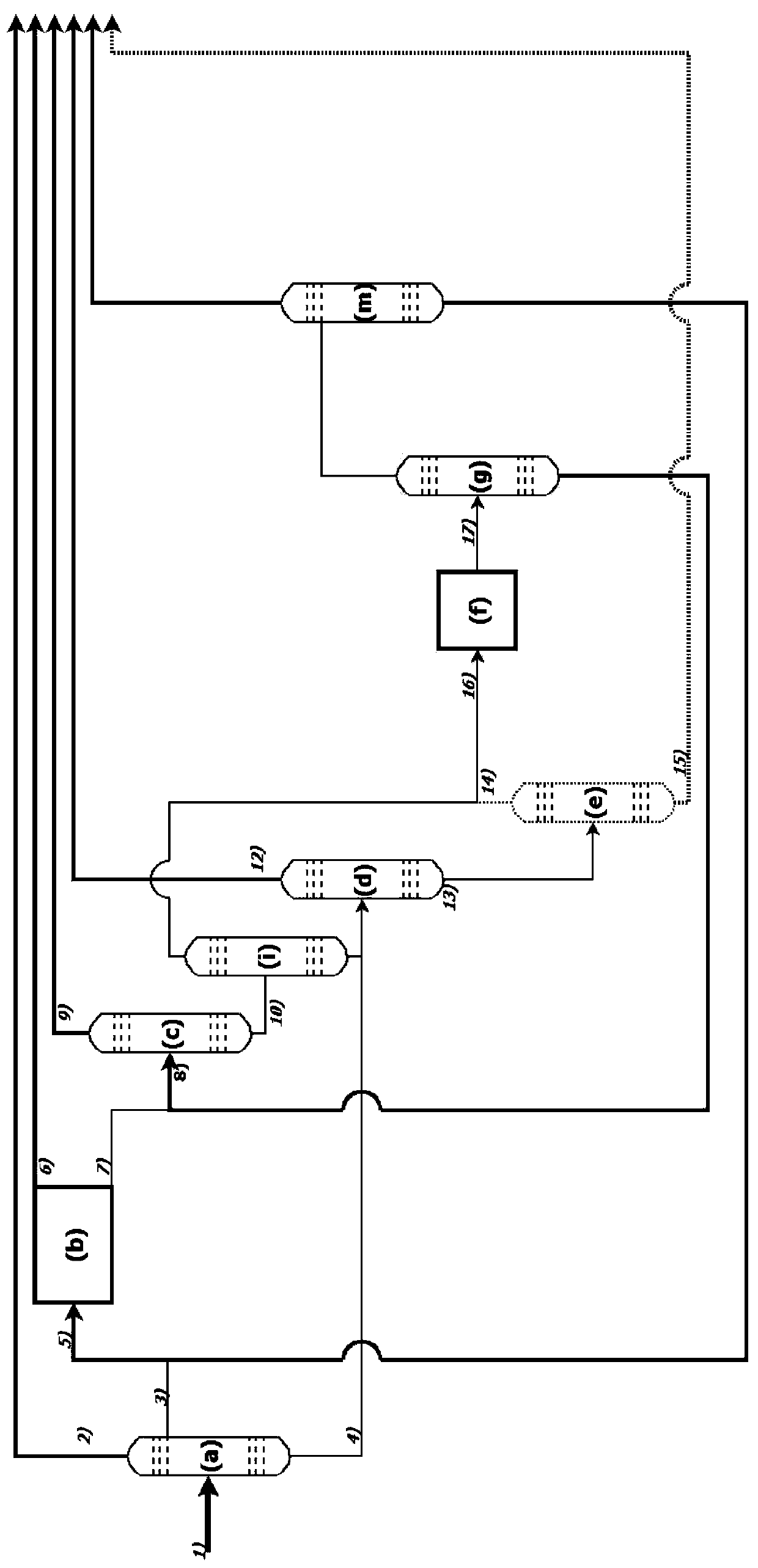

[0052] According to the reference process flow corresponding to the prior art (see figure 1 ), the toluene tower mainly plays the role of separating the A8+ produced from the transalkylation of toluene.

[0053] The present invention describes a fractionation process for an aromatics complex in which the fractionation point of the effluent fractionation column of the transalkylation unit is changed and the toluene column is omitted. A light aromatic fraction (denoted BT) consisting of a benzene / toluene fraction is withdrawn from the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com