A dynamic engine deactivation reforming control method and control system thereof

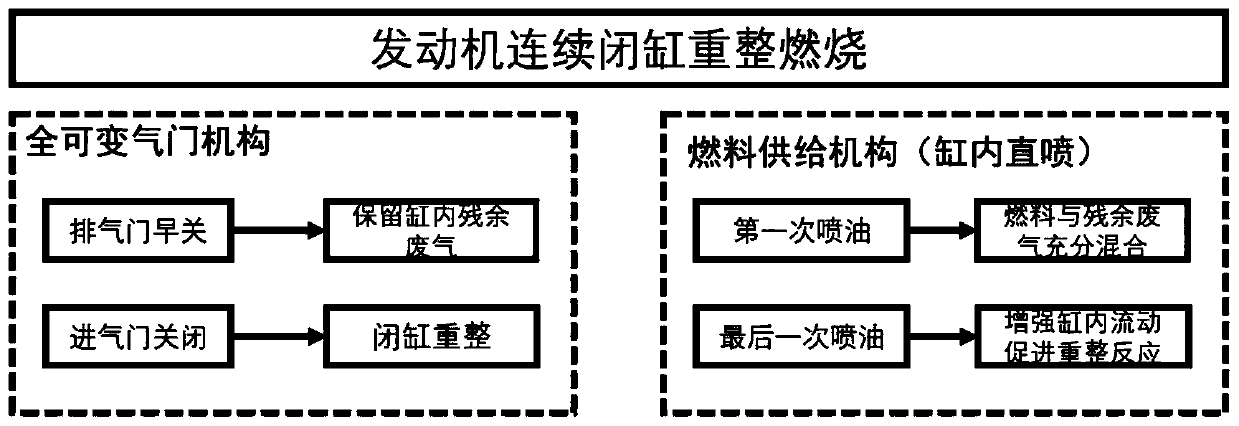

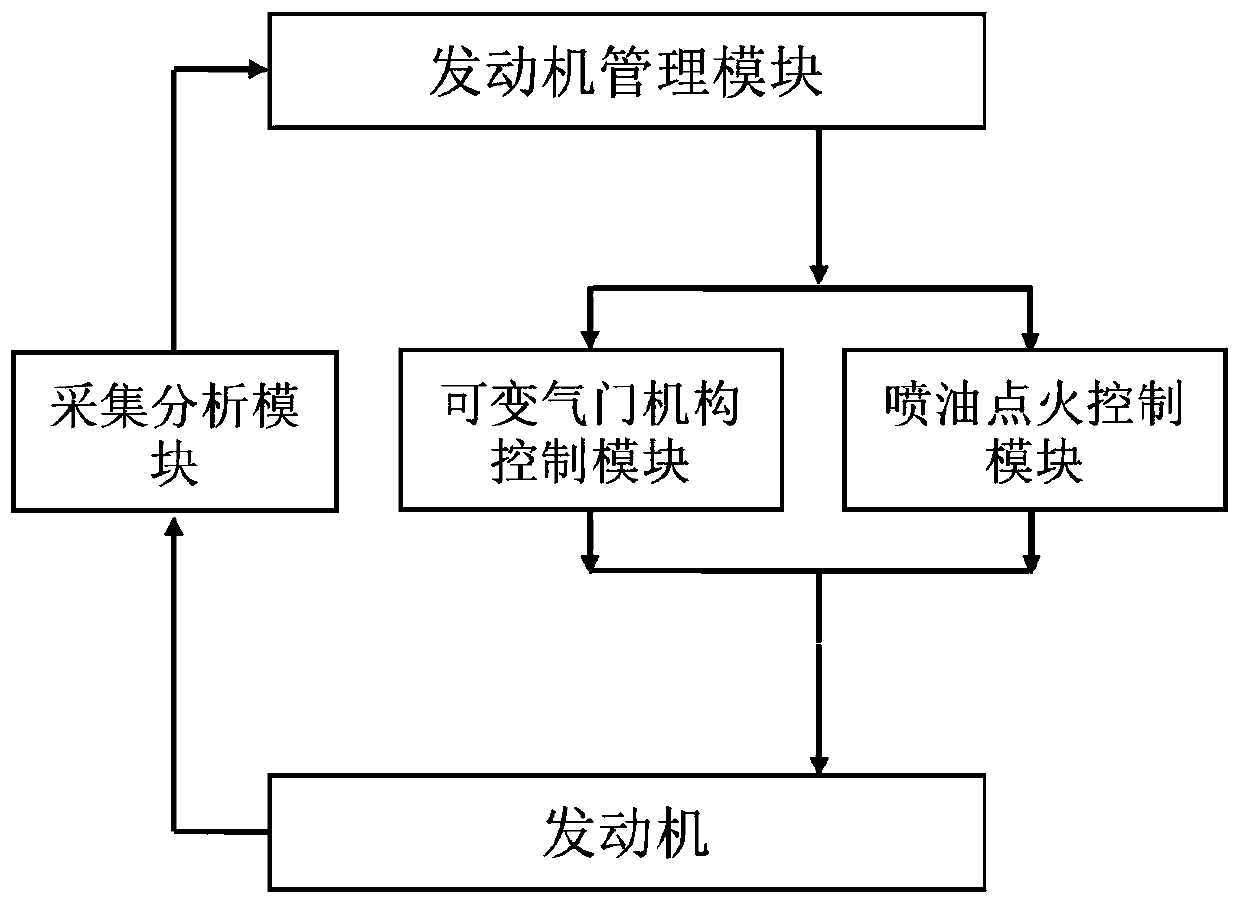

A control method and engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of difficult ignition and combustion, unstable combustion, etc., to stabilize the combustion process in the cylinder, avoid poor economy, reduce less economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

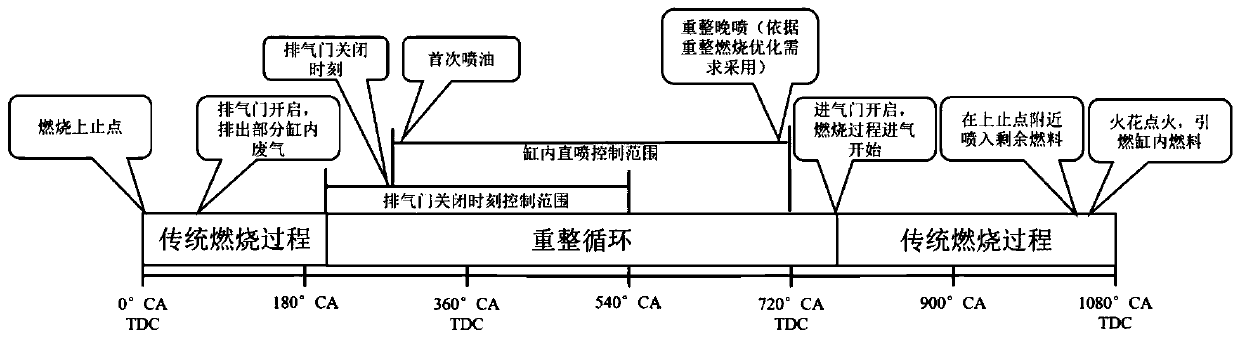

[0053] 1. With the combustion top dead center as 0°CA, the exhaust valve is closed at 240°CA after top dead center, and the residual exhaust gas in the cylinder is used to retain part of the residual exhaust gas in cylinder 1;

[0054] 2. Inject 25% gasoline (2.552mg) into the cylinder at 360°CA, and expand and compress together with the residual exhaust gas in the cylinder, and the valve does not open during this process;

[0055] 3. Spray 25% gasoline (2.552mg) into the cylinder at 700°CA to enhance the flow in the cylinder and the contact area between exhaust gas and fuel, and promote the reforming reaction;

[0056] 4. The piston descends, the intake valve opens at 743°CA, the cylinder begins to intake air, and enters the combustion stage;

[0057] 5. The intake valve is closed at 874°CA, and the remaining 50% gasoline (5.100mg) is injected into the cylinder at 1040°CA, and then the spark plug is ignited at 1060°CA to ignite the mixture and complete the combustion process;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com