A simulation calculation method for temperature rise characteristics of transformer windings

A technology of transformer winding and simulation calculation, applied in the field of simulation, can solve the problems of ignoring the influence of temperature rise characteristics, unfavorable practical application, and many factors of heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

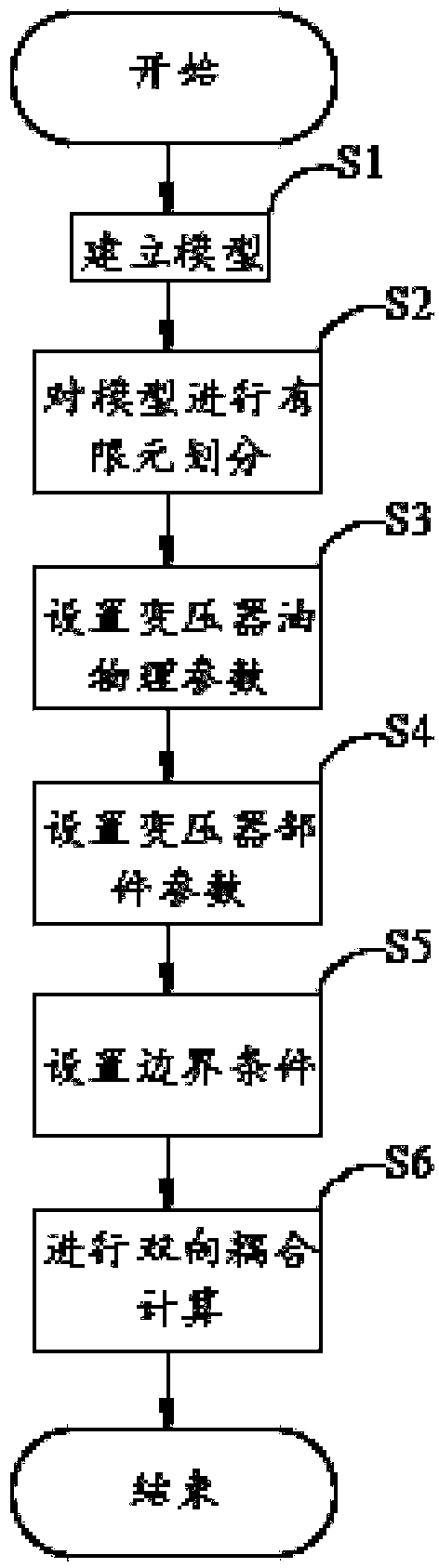

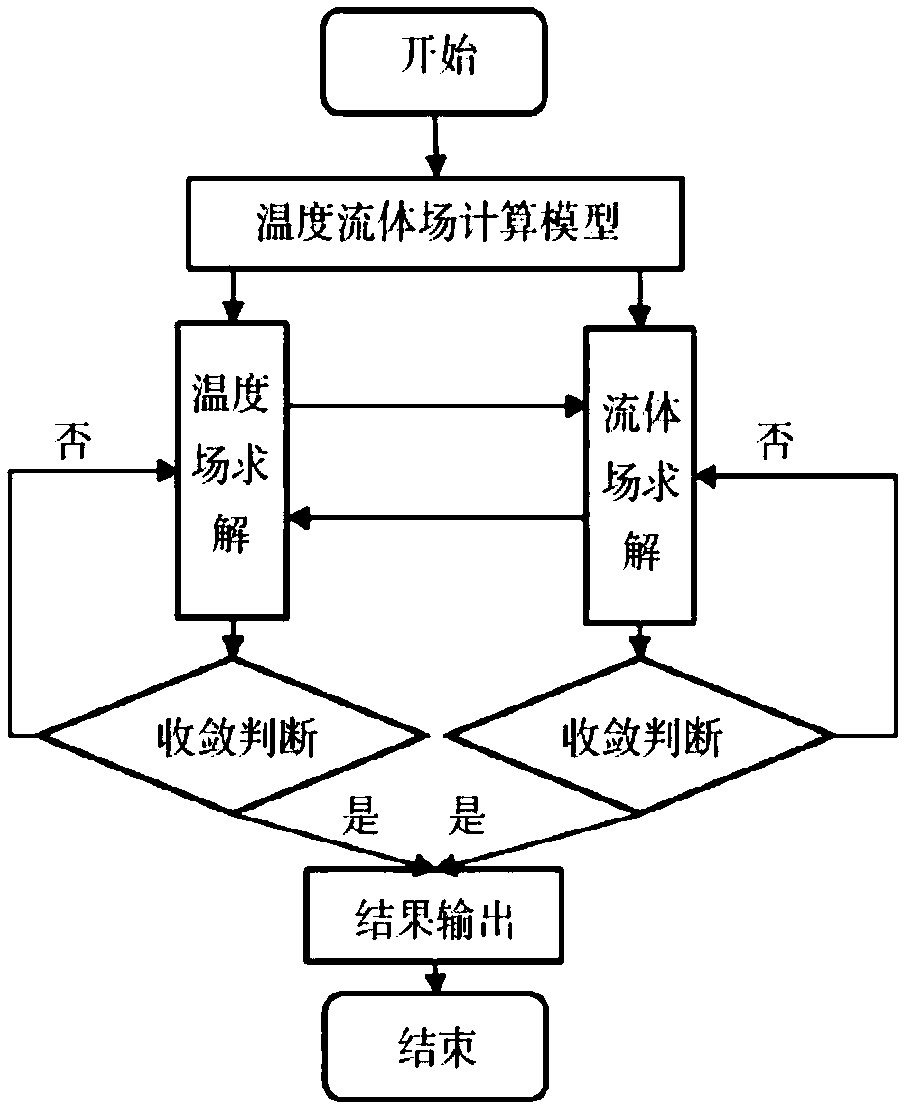

[0035] Such as figure 1 Shown is a simulation calculation method for the temperature rise characteristics of a transformer winding according to the present invention, including the following steps:

[0036] S1: Build a model: build a model in the finite element simulation software according to the actual size of the transformer's oil tank, high-voltage winding, low-voltage winding and iron core;

[0037] Specifically: in the process of building the model, select the single item analysis of the transformer, establish a two-dimensional axisymmetric model, set the core center as the symmetrical axis; set the winding parameters of the low-voltage side of the power transformer, the winding parameters of the high-voltage side, the oil channel parameters, the core parameters and The parameters of the oil tank; the heat source only considers the iron core and the high and low voltage windings; the temperature of the high and low voltage windings of the transformer along the circumfere...

Embodiment 2

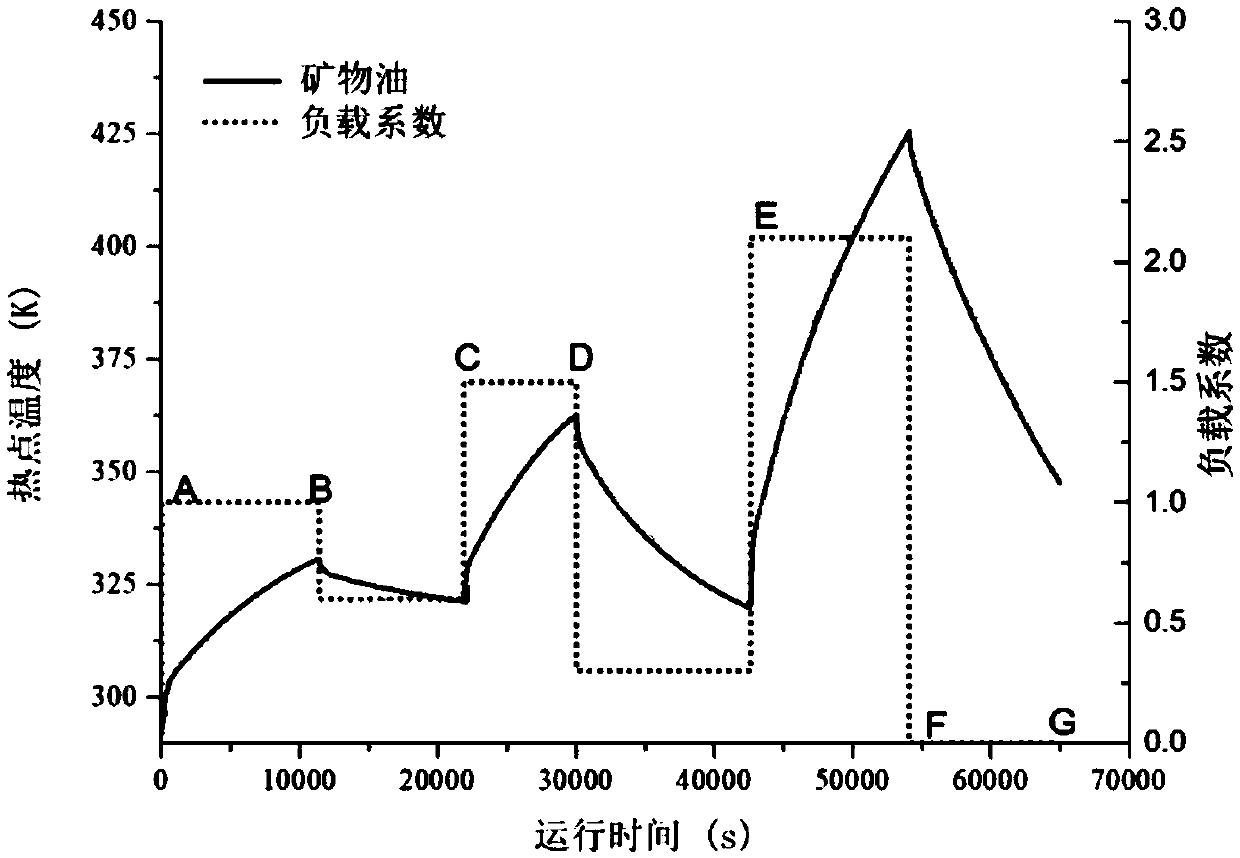

[0061] The model used in this embodiment is a 35kV / 315kVA oil-immersed transformer. The transformer is simulated based on the simulation method of transformer temperature rise characteristics under dynamic load of ANSYS Fluent. The specific steps are as follows:

[0062] S1, build a model: build a model in finite element simulation software (ANSYS) according to the actual size of transformer oil tank, winding and iron core;

[0063] Specifically, in this embodiment, the height of the oil tank is set to 1070mm, and the width is 255mm; the height of the iron core is 840mm, and the width is 87.5mm; The gap width is 5mm; the height of the high-voltage winding is 378mm, and the width is 40mm; the width of the oil gap between the iron core and the low-voltage winding is 6.5mm, the width of the oil gap between the low-voltage and high-voltage winding is 20mm, and the width of the oil gap between the high-voltage winding and the tank wall is 75mm; The bottom of the fuel tank is 12mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com