New vehicle battery dissipation preheating and collision avoidance system

An anti-collision system and vehicle technology, applied in secondary batteries, battery temperature control, battery pack components, etc., can solve the problems of high temperature flammability, low low temperature charge and discharge efficiency, weak protection strength, etc. Life, improve charge and discharge efficiency and protection level, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

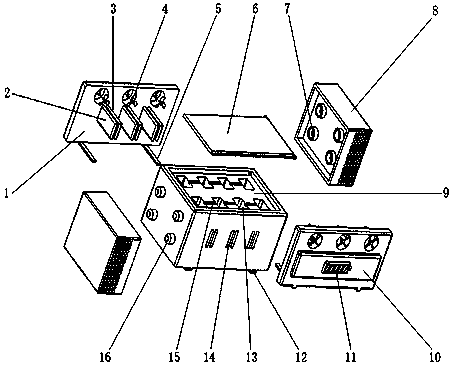

[0019] Such as figure 1 As shown, it is characterized in that: the heat dissipation unit, the preheating unit and the control unit are arranged on the same side plate 1, and are all symmetrically installed on the lateral sides of the foam aluminum box 9, and the anti-collision unit Symmetry is installed on the longitudinal both sides of foamed aluminum casing 9. The box cover 6 is installed on the upper surface of the foamed aluminum box 9; the side plate 1 is symmetrically installed on the lateral sides of the foamed aluminum box 9 through the positioning rod 5 and the positioning groove 12; the three fans of the heat dissipation unit 4. Three heat dissipation heat pipes 2, three heating heat pipes 3 of the preheating unit, a controller 10, and an auxiliary power supply 11 are sequentially installed on the side plate 1; one end of the spring damper 16 is installed on a longitudinal surface of the aluminum foam box 9, The other end is installed on the damper mounting base 7; ...

example 2

[0024] The working process of a new type of vehicle battery cooling and preheating and anti-collision system of the present invention is as follows:

[0025] 1. The heat dissipation unit and preheating unit of this system start to work when they get the command to unlock the central control door, and stop working 5 minutes after they get the command to lock the door from the central control

[0026] 2. When the temperature sensor set in the aluminum foam box 9 senses that the box temperature is 30°C~40°C (the temperature at both ends of the interval only includes 30°C), the foamed aluminum box and the phase change material set in the foamed aluminum box will and the two fans 4 installed on the side plate 1 for primary heat dissipation; when the temperature is between 40°C and 50°C (the temperature at both ends of the range only includes 40°C), four fans 4 are turned on on the basis of the primary heat dissipation for heat dissipation. Two-level heat dissipation; when the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com