A lithium battery bus piece device and a method thereof

A technology for busbars and lithium batteries, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as the inability to reach the same height of the welding surface, the quality of welding cannot be guaranteed, and the quality of the battery module is affected. False soldering, increased contact area, and excellent over-current capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

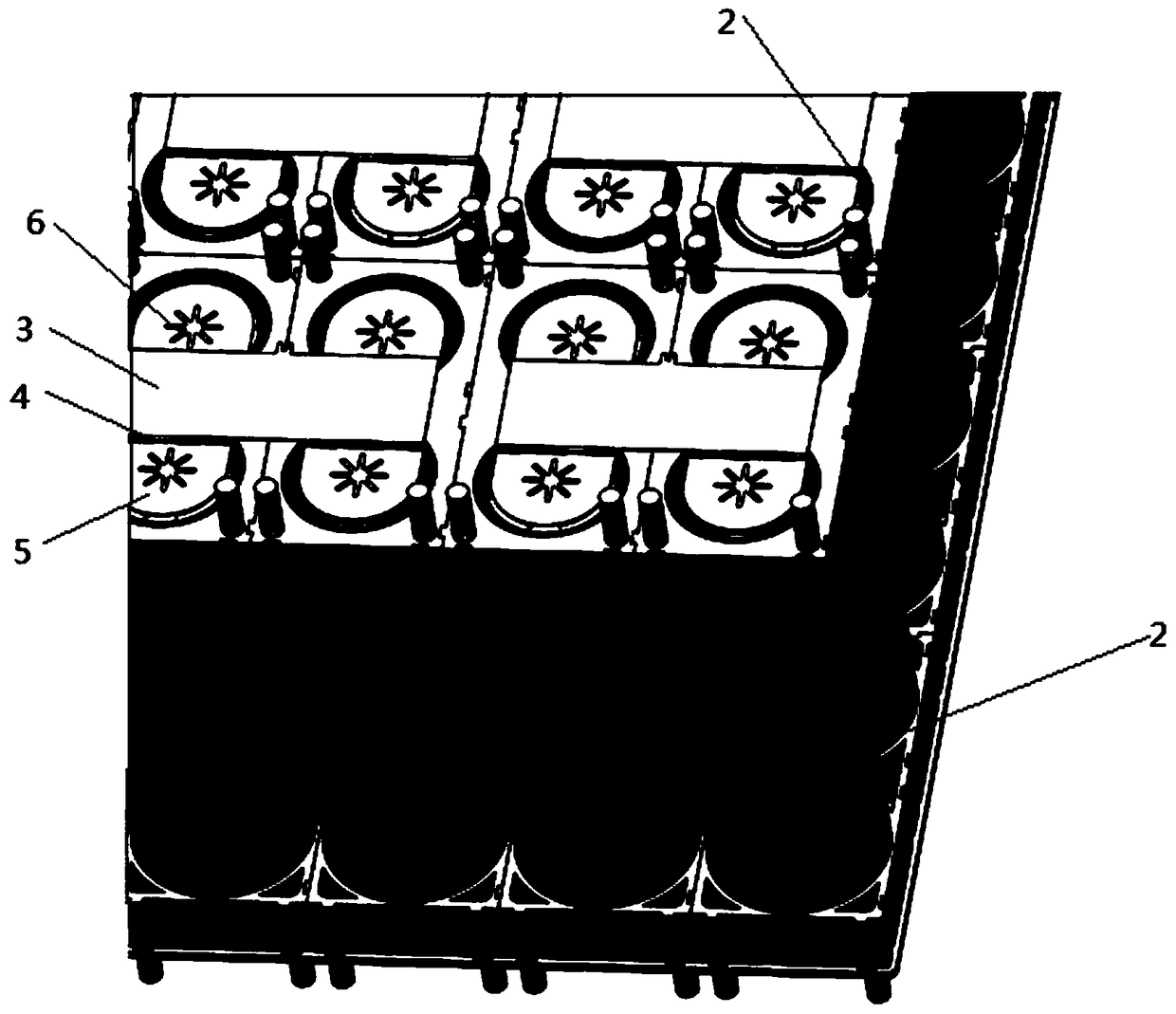

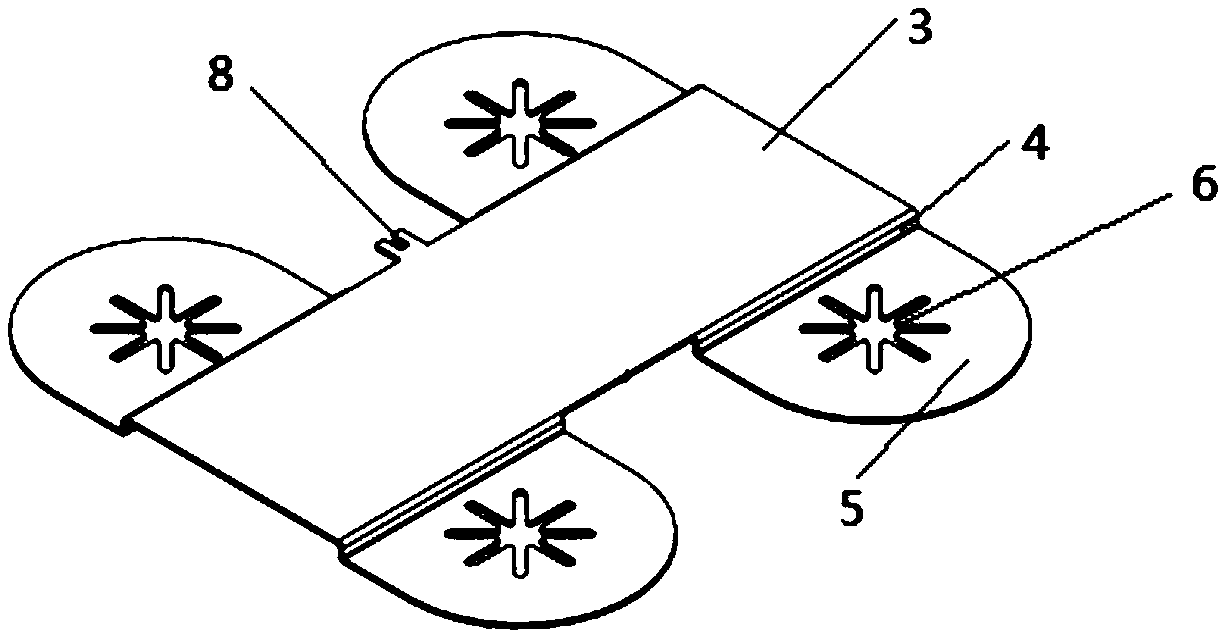

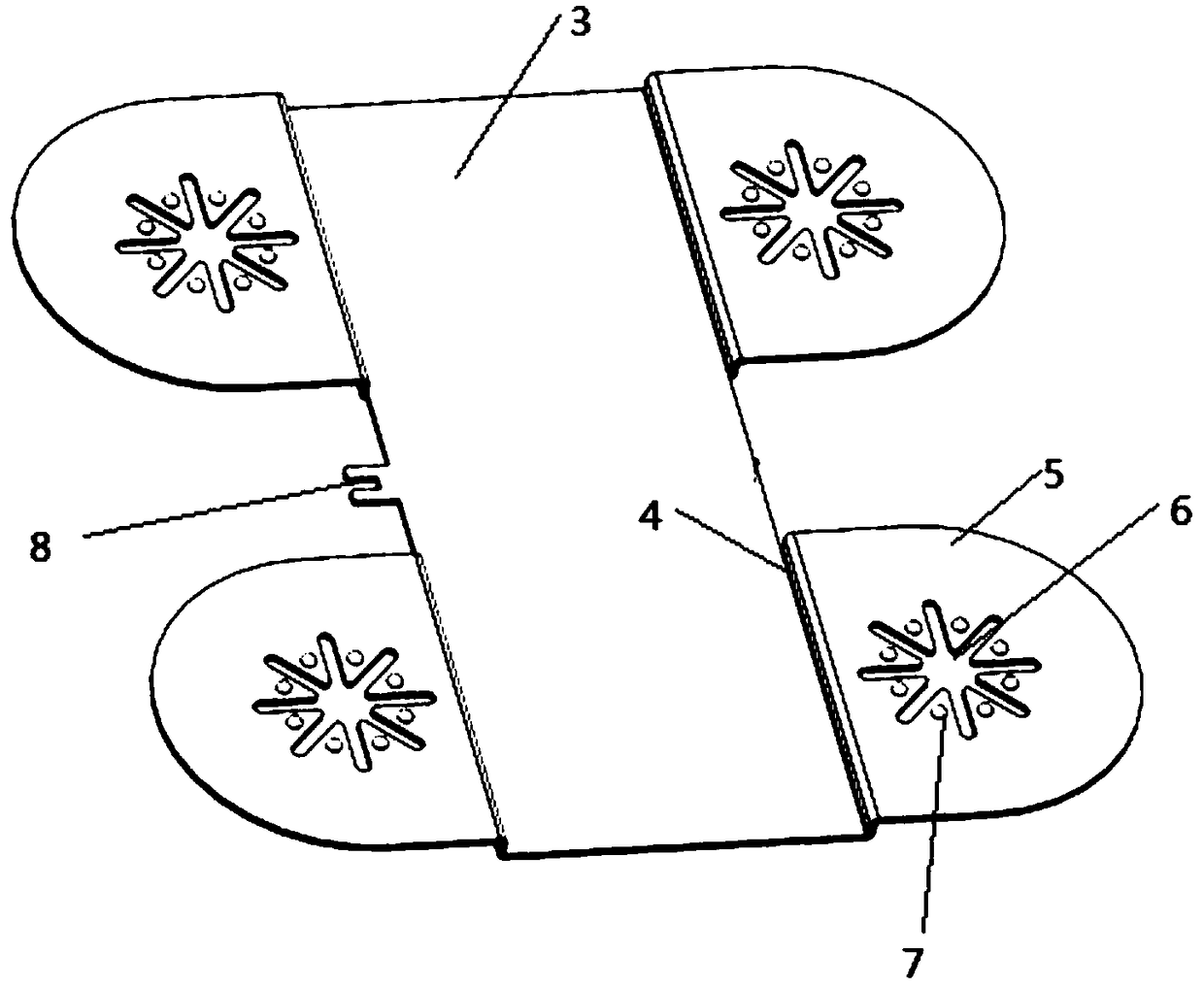

[0040] Such as Figure 1-Figure 6As shown, the lithium battery busbar device includes a sheet-shaped busbar 1, and the busbar 1 forms a contact portion with the battery cell 2 of the lithium battery through a bent structure for better contact. The busbar 1 includes a sheet-like middle section 3 with a rectangular parallelepiped structure, and the opposite sides of the sheet-like middle section 3 are integrally connected with an even number of downward-turning bending structures mirrored on the two sides, and each bending The structures all include a sheet-like horizontal section 5 and a sheet-like vertical section 4 of a rectangular parallelepiped structure. One end of section 5 is integrally connected; flaky horizontal section 5 is exactly the contact part, and the other end of flaky horizontal section 5 is round head shape, removes the other end of flaky horizontal section 5 round head shape, the rest of flaky horizontal section 5 Some are cuboid structures. The top wall o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com