Hydraulic clamp for positioning and automatically clamping thin-walled steel sleeve through inner hole and using method thereof

A hydraulic, thin-walled technology, applied in the field of mechanical manufacturing and processing, to achieve the effect of replacing human labor, high centering accuracy, and avoiding workpiece deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

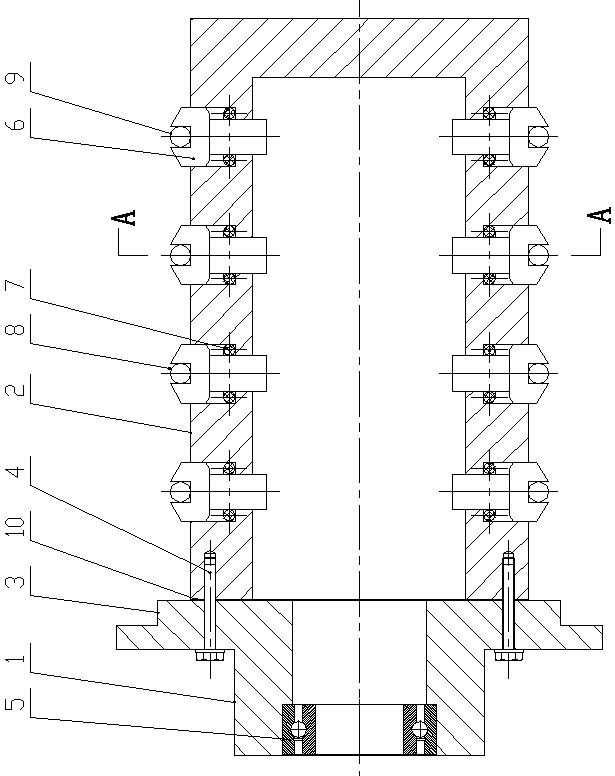

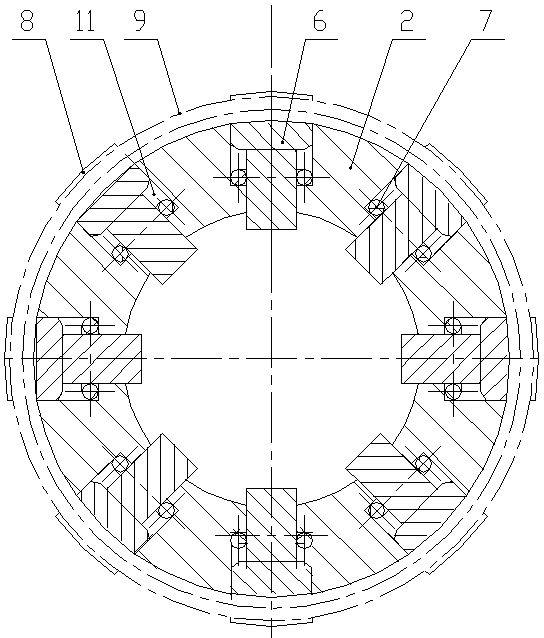

[0019] Such as figure 1 and figure 2 As shown, the hydraulic clamp for automatically clamping the thin-walled steel sleeve with the positioning of the inner hole of the present invention includes a left and right transparent connecting cylinder 1 and a cylinder 2 with an open left end, and the right end of the connecting cylinder 1 is fixedly connected to the coaxial line with a flange 3 , the flange 3 is fixedly connected to the coaxial line at the left end of the cylinder 2 through the bolt 4, the inner wall of the left port of the connecting cylinder 1 is provided with a bearing 5 for connecting the hydraulic oil pipe, and the outer circle of the cylinder 2 is evenly arranged with several groups of structures along the axial direction The same radial telescopic clamping mechanism.

[0020] Each set of radially telescopic clamping mechanisms includes several stepped holes 11 that are thick on the outside and thin on the inside. The stepped holes 11 are evenly arranged alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com