Method for increasing fragrance of polyurethane foaming product

A polyurethane and product technology, which is applied in the field of increasing the fragrance of polyurethane foam products, can solve problems such as irritation and affecting comfort, and achieve the effects of reducing peculiar smell, eliminating ammonia smell, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

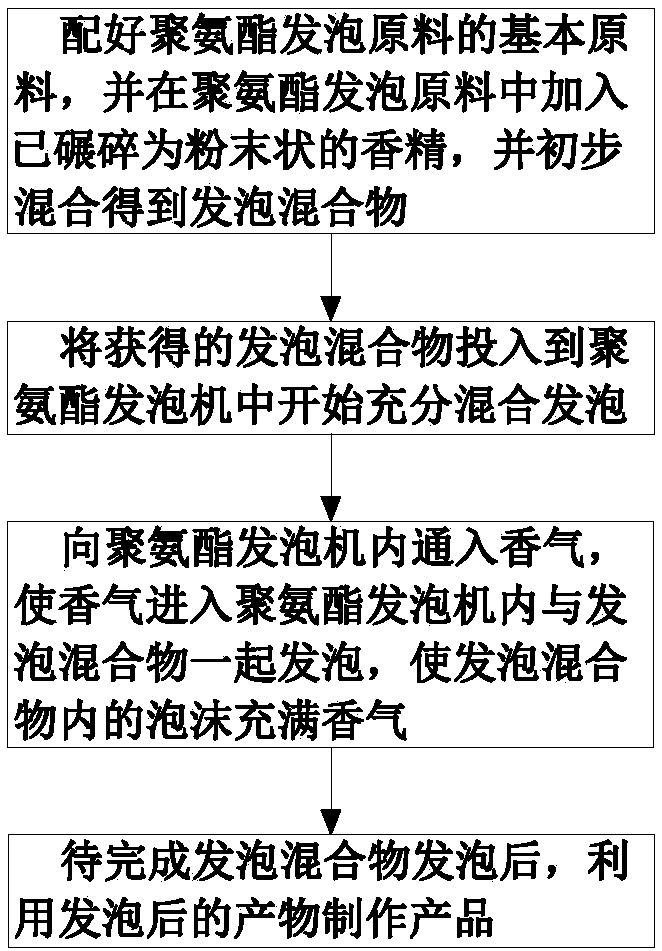

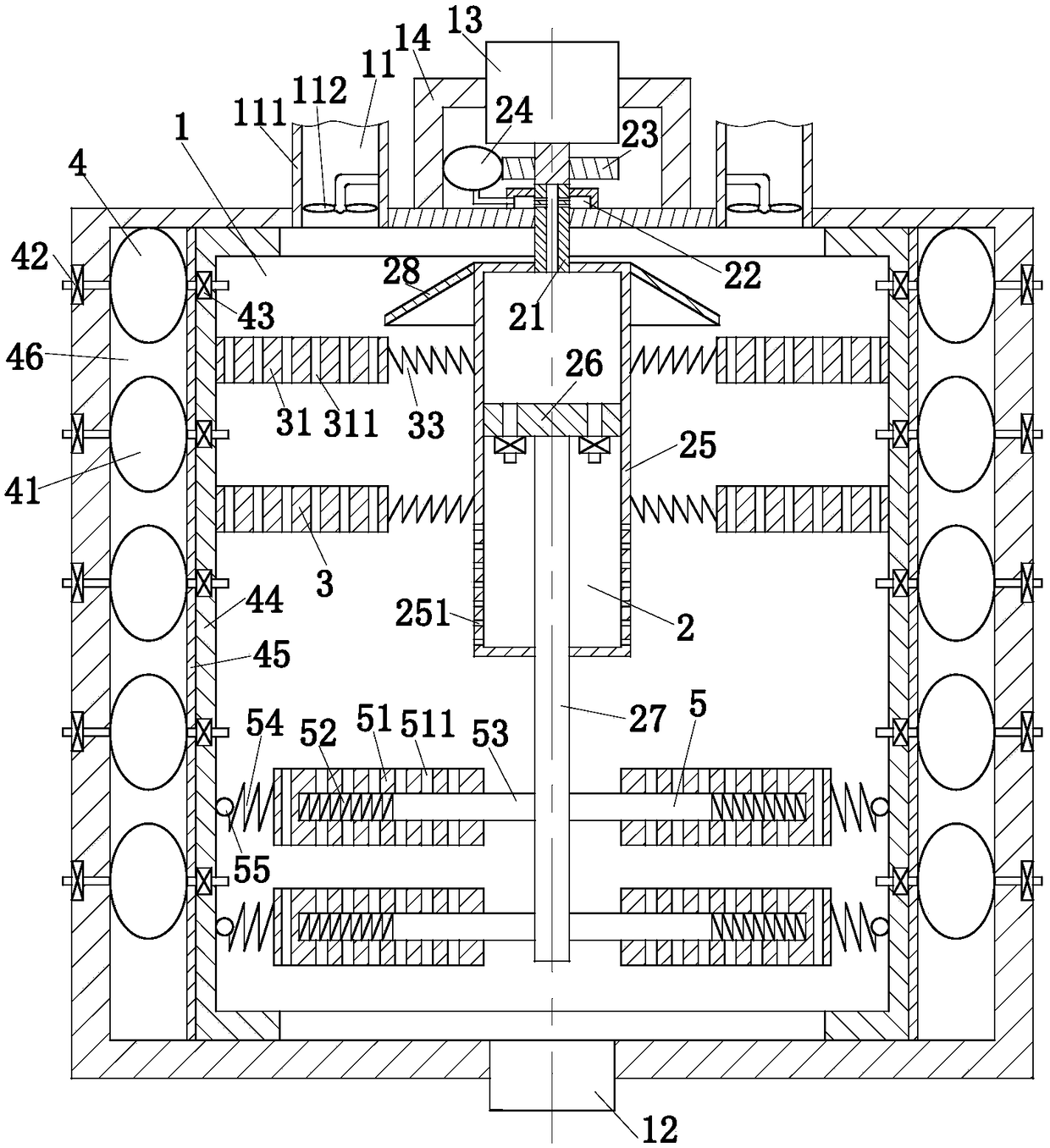

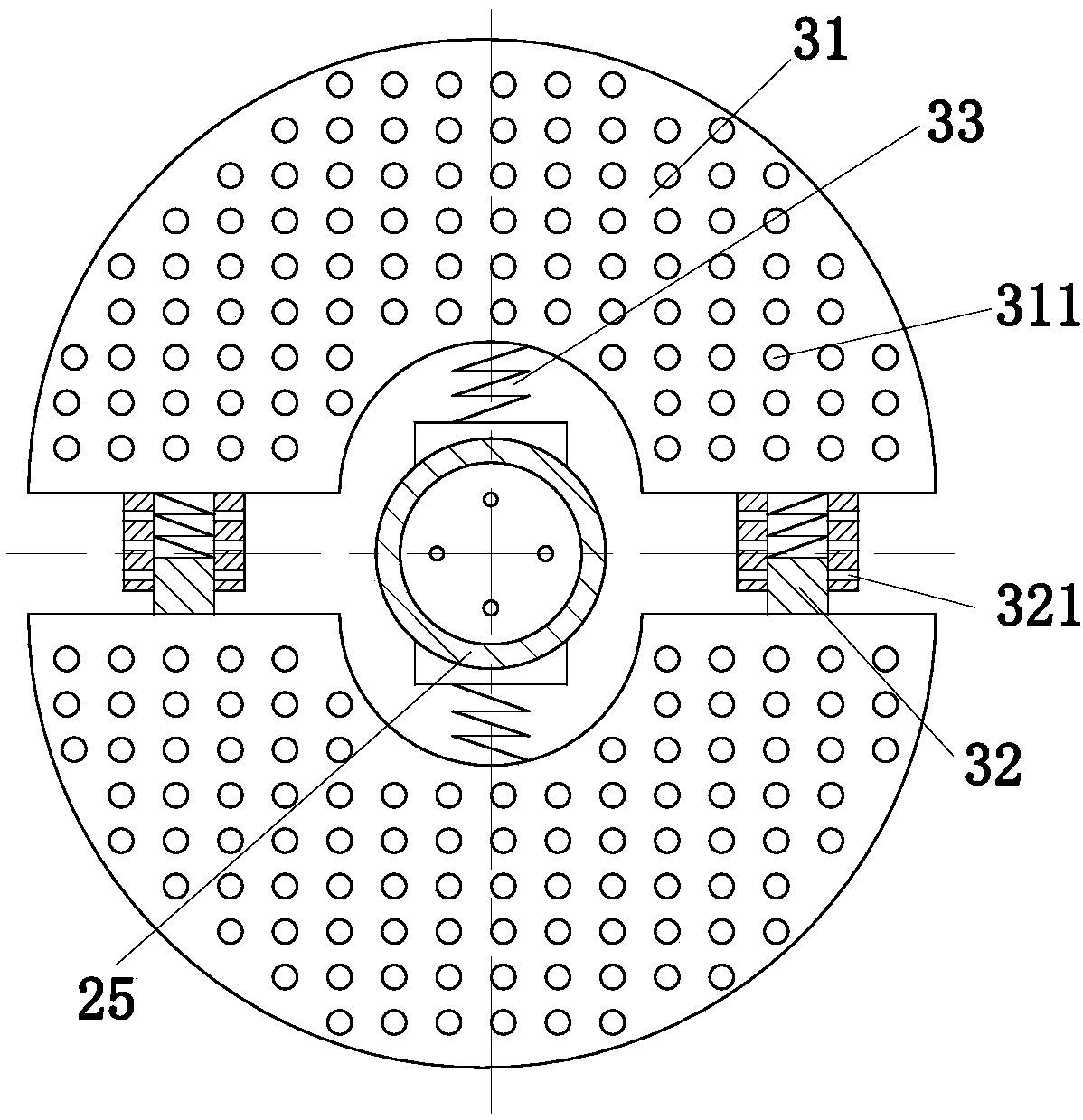

[0027] use Figure 1 to Figure 3 A method for increasing the fragrance of a polyurethane foam product according to an embodiment of the present invention is described as follows.

[0028] Such as Figure 1 to Figure 2 Shown, a kind of method that increases polyurethane foam product fragrance of the present invention, this method comprises the following steps:

[0029] S1: prepare the basic raw materials of polyurethane foam raw materials, and add the essence that has been crushed into powder to the polyurethane foam raw materials, and initially mix to obtain a foam mixture; the aroma is lavender, osmanthus, jasmine, orchid One of , rose, fruit, flower and essential oil flavors;

[0030] S2: Put the foaming mixture obtained in S1 into the polyurethane foaming machine to start fully mixing and foaming;

[0031] S3: When S3 starts to foam the foaming mixture, introduce aroma into the polyurethane foam machine, make the elastic airbag 1 24 and elastic airbag 2 41 inhale the aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com