Double-hearth lime kiln with gas and coal mixed combustion

A double-chamber lime kiln and co-firing technology, applied in the field of lime kiln, can solve the problems of low utilization rate of lime kiln, low utilization rate of low calorific value gas, and large coal consumption, so as to improve the utilization rate and scope of application, and save coal The use of powder and the effect of saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

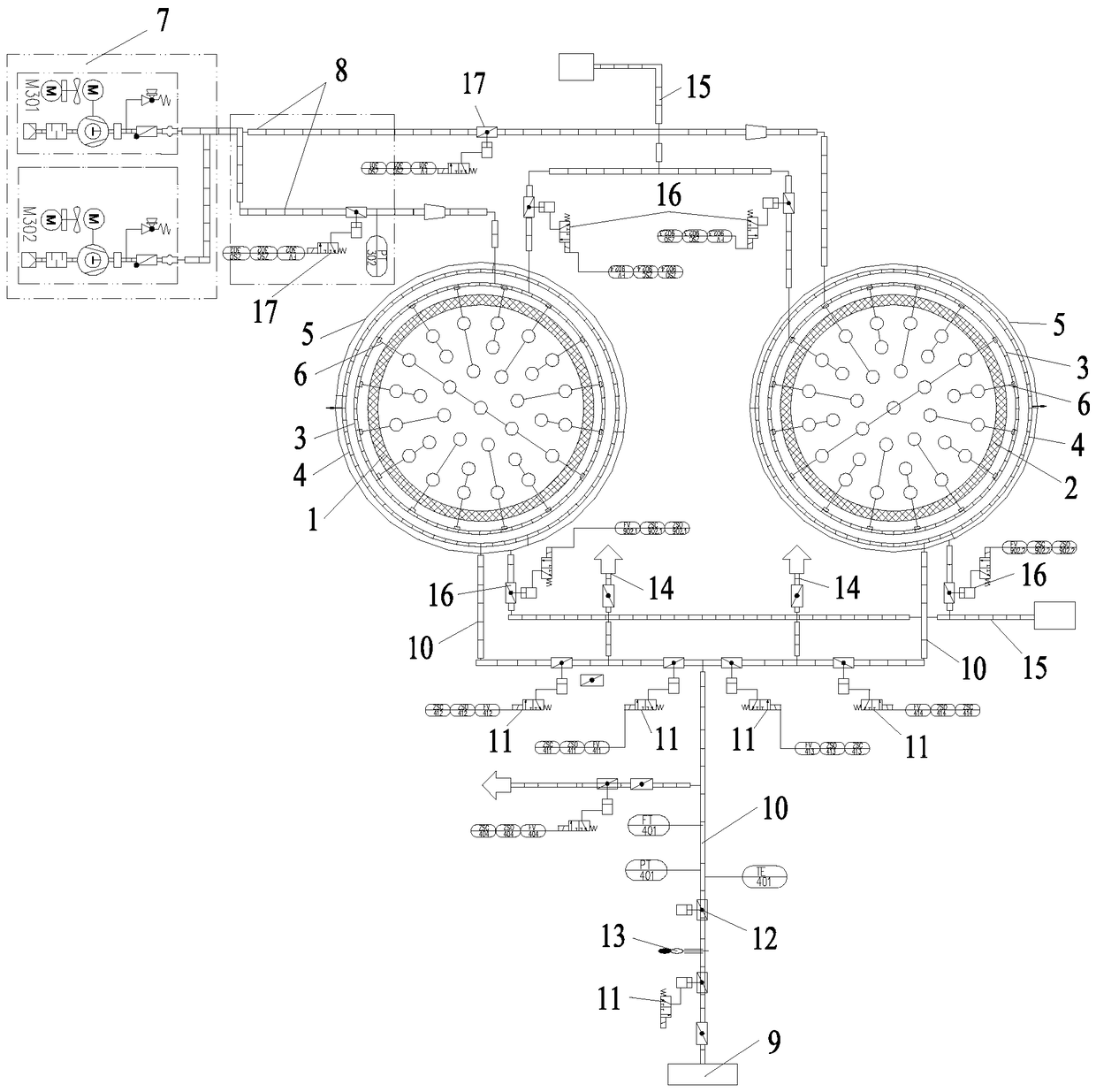

[0019] Such as figure 1 As shown, this embodiment discloses a gas-coal mixed-fired double-chamber lime kiln, including a first kiln chamber 1 and a second kiln chamber 2, and the outer walls of the first kiln chamber 1 and the second kiln chamber 2 are connected There are spray gun ring pipe 3, gas ring pipe 4 and nitrogen ring pipe 5, the gas ring pipe 4 and the spray gun ring pipe 3 are all connected with the nitrogen ring pipe 5, and the nitrogen ring pipe 5 is used to connect the gas ring pipe 4 and the spray gun ring pipe 3 for periodic purging, the spray gun ring pipe 3 is also connected with the fan 7, the gas ring pipe 4 is connected with the gas pressurizer 9, the nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com