Flexible waterproof cushion and preparation method thereof

A waterproof cushion and elastic technology, which is applied in the field of thin-walled light steel structure prefabricated buildings, can solve problems affecting the stability of the structure, the deformation and displacement of the main body, and the weak combination of the structure and the foundation, so as to achieve structural stability and convenient construction , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a cushion layer and a preparation method thereof, comprising the following steps:

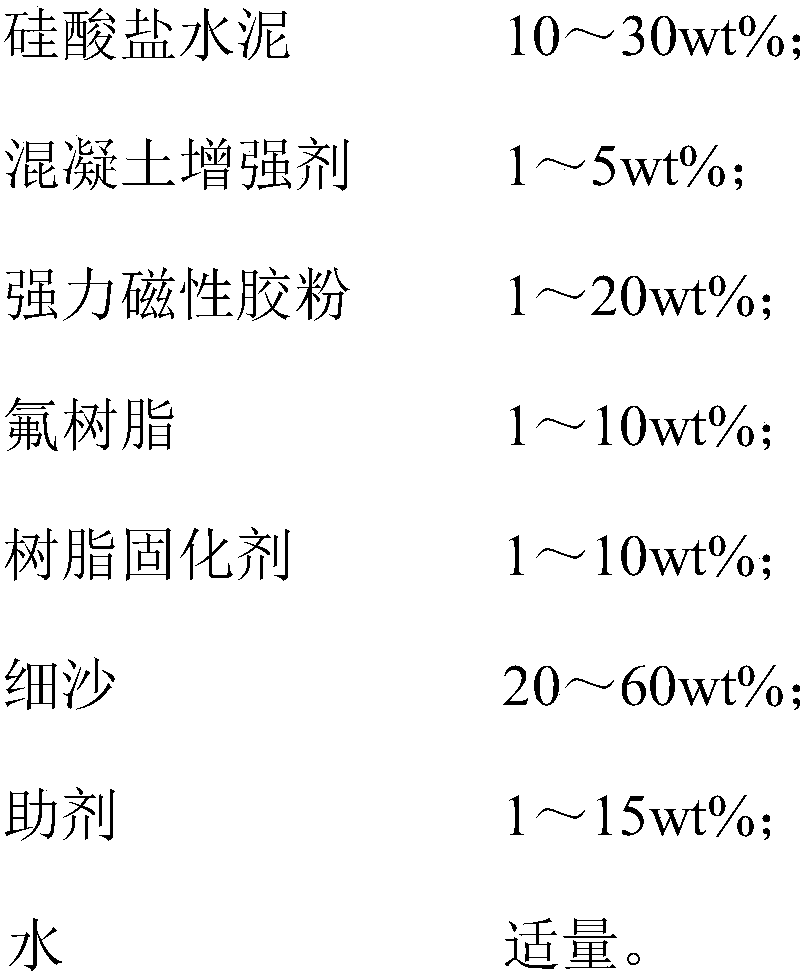

[0035] Step 1, take each raw material according to the following weight percentages:

[0036]

[0037]

[0038] Step 2. Preprocessing

[0039] Pretreatment of RG-10 concrete reinforcing agent: put the above concrete reinforcing agent into a stainless steel container, then add purified water twice the weight of the concrete reinforcing agent, stir and mix evenly, and use it as a raw material for production.

[0040] Pretreatment of kld-315 strong magnetic rubber powder: Put the above strong magnetic rubber powder into a stainless steel container, then add purified water of 1 times the weight of the strong magnetic rubber powder, stir and mix evenly, and use it as a raw material for production.

[0041] Pretreatment of the resin curing agent: put the HDI biuret curing agent into a stainless steel container, then add purified water 1 times the weight of the r...

Embodiment 2

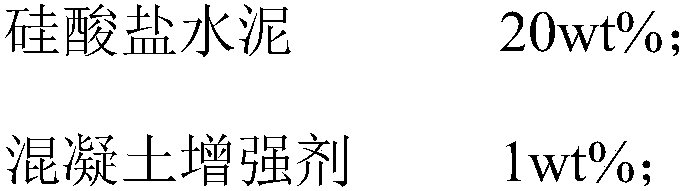

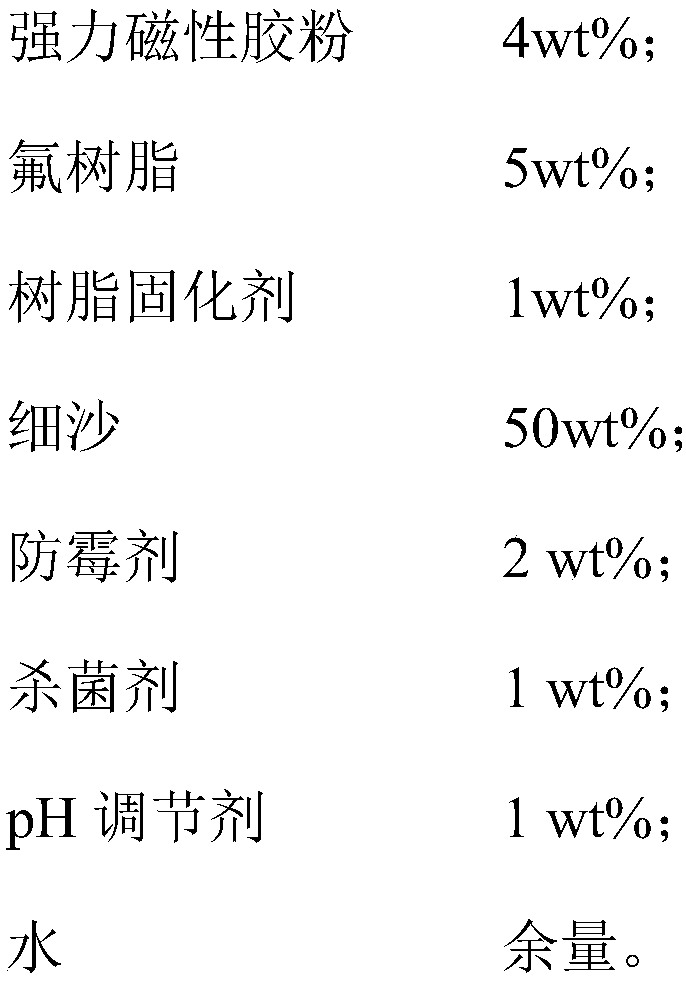

[0051] The present embodiment provides a kind of cushion layer, and its preparation method is basically the same as embodiment 1, and the difference is that the weight percentage of each raw material is as follows:

[0052]

[0053]

[0054] With reference to the national standard GB / T 23445-2009, the performance test of the above-mentioned elastic waterproof cushion is carried out. The test items and test results are shown in Table 2:

[0055] Table 2

[0056]

Embodiment 3

[0058] The present embodiment provides a kind of cushion layer, and its preparation method is basically the same as embodiment 1, and the difference is that the weight percentage of each raw material is as follows:

[0059]

[0060] With reference to the national standard GB / T 23445-2009, the performance test of the above-mentioned elastic waterproof cushion is carried out. The test items and test results are shown in Table 3:

[0061] table 3

[0062]

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com