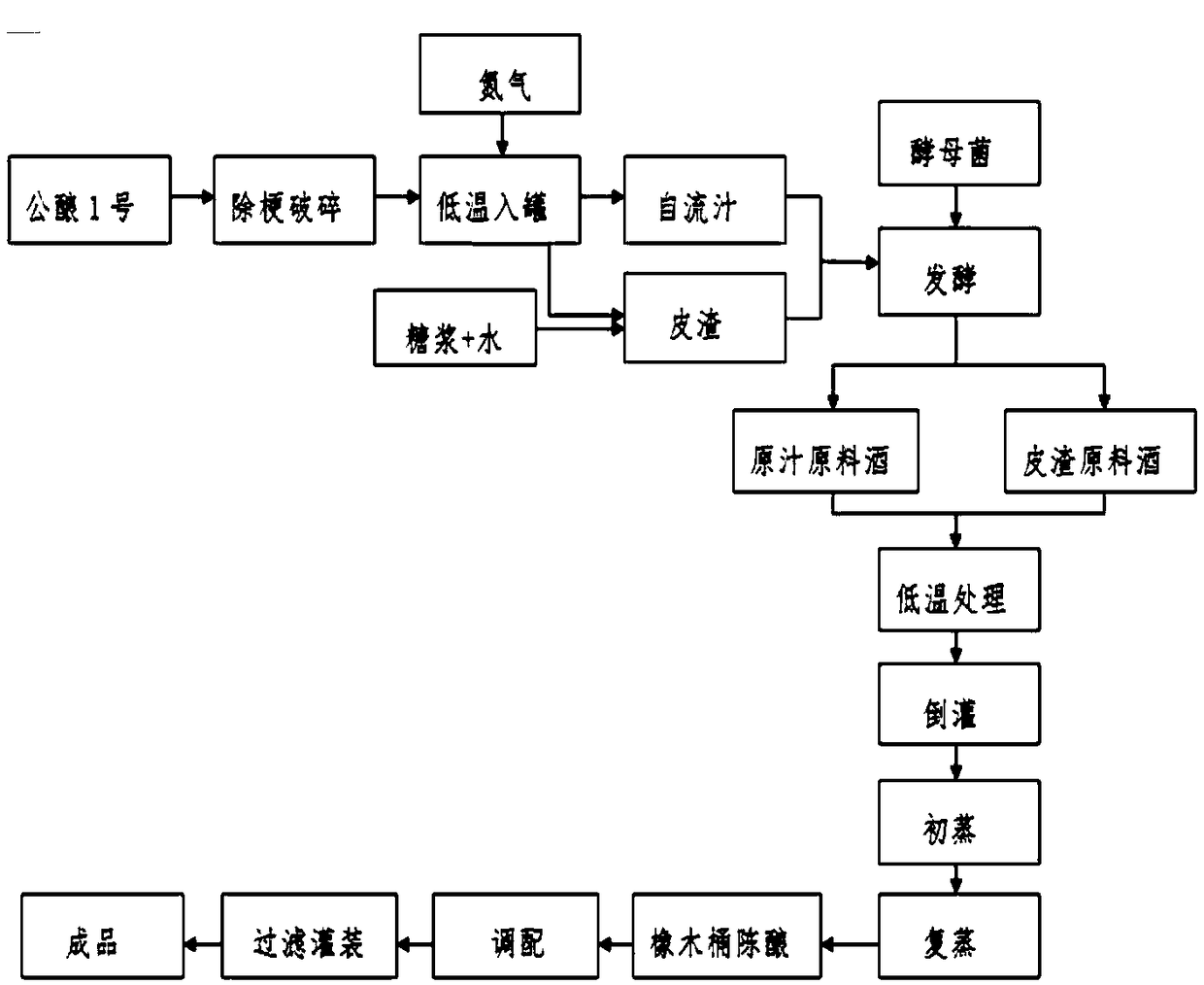

Brewing process for brandy

A brandy and craftsmanship technology, applied in the field of wine making, can solve the problems of unpleasant green flavor, strong green flavor, unbalanced taste, etc., and achieve the effect of rich aroma, long aftertaste and sweet aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

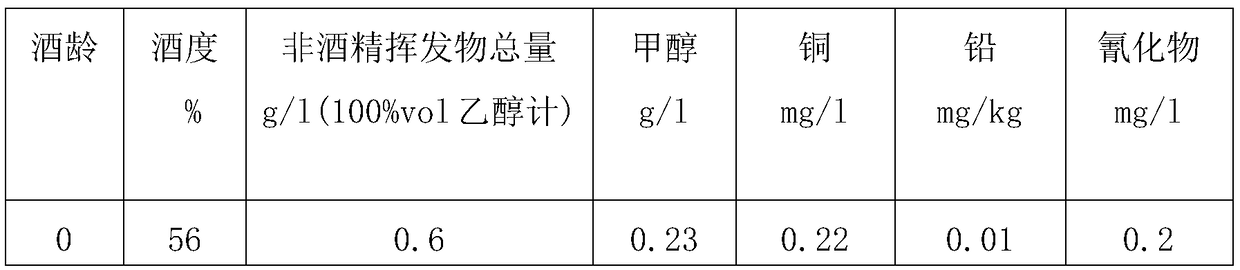

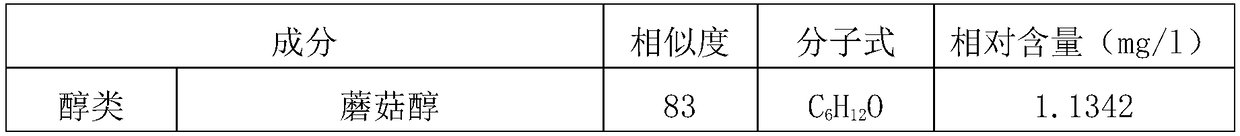

Embodiment 1

[0030] A brandy brewing process, comprising the following steps:

[0031] (1) Raw material treatment: destemmed the "Gongniang No. 1" grapes and crushed them. After entering the tank, the artesian juice was released immediately under the protection of nitrogen. The volume of the extracted artesian juice accounted for 30% of the total volume of the tank. For glucose syrup with the same sugar content as berries, the added volume is 40% of the volume of artesian juice extracted.

[0032] (2) Fermentation: Clarify the artesian juice obtained in step 1 at 6°C for 12 hours at low temperature, pour the tank back to 12°C, add 150 mg / l yeast, and ferment at 14°C under temperature control until the residual sugar drops to Fermentation is terminated below 4g / L, the temperature is lowered to 10°C, and after clarification for 48 hours, the tank is poured out. Add 200mg / l yeast to the skin dregs, and ferment under temperature control at 14°C until the residual sugar drops below 4g / L to sto...

Embodiment 2

[0048] A brandy brewing process, comprising the following steps:

[0049] (1) Raw material treatment: destemming and crushing the public brewed grapes, release the artesian juice immediately after entering the tank under the protection of nitrogen, the volume of the extracted artesian juice accounts for 35% of the total volume of the tank, and add the remaining pomace to the same sugar content as the original grape berries For glucose syrup, the added volume is 50% of the volume of the artesian juice extracted.

[0050] (2) Fermentation: Clarify the original juice at 6°C for 24 hours at low temperature, pour the tank back to 12°C, add 200mg / l yeast, and ferment at 16°C under temperature control until the residual sugar drops below 4g / L Terminate the fermentation, lower the temperature to 8°C, and after clarification for 24 hours, pour the tank. Add 250mg / l yeast to the skin dregs, and ferment under temperature control at 14°C until the residual sugar drops below 4g / L to stop ...

Embodiment 3

[0070] A brandy brewing process, comprising the following steps:

[0071] (1) Raw material treatment: Destemming and crushing the public brewed grapes, release the artesian juice immediately after entering the tank under the protection of nitrogen, the volume of the extracted artesian juice accounts for 40% of the total volume of the tank, and add the remaining pomace to the same sugar content as the original grape berries Glucose syrup, the added volume is 45% of the volume of artesian juice extracted.

[0072] (2) Fermentation: Clarify the raw juice at 6°C for 48 hours at low temperature, pour the tank back to 12°C, add 200mg / l yeast, and ferment at 15°C under temperature control until the residual sugar drops below 4g / L Terminate the fermentation, cool down to 10°C, and after clarifying for 36 hours, pour the tank. Add 200mg / l yeast to the skin dregs, and ferment under temperature control at 15°C until the residual sugar drops below 4g / L to stop the fermentation, separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com