Low-yield-ratio high-intensity hardened and tempered steel for coal mine hydraulic support frame and manufacturing method of low-yield-ratio high-intensity hardened and tempered steel

A low yield ratio, coal mine hydraulic technology, applied in low yield ratio high strength quenched and tempered steel and its manufacture, low yield ratio quenched and tempered steel, coal mine hydraulic support manufacturing field, can solve high yield ratio and other problems, Achieve the effects of low yield ratio, good toughness and plasticity, and low crack sensitivity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the following, the process of obtaining quenched and tempered steel with low yield strength ratio by quenching and tempering steel with a low yield strength ratio is taken as an example to further illustrate the present invention by using a steel plate with a product specification of 20 mm produced by a steel coil rolling mill production line through two-phase zone quenching. In this embodiment, the quenched and tempered steel is proportioned by weight percentage, including the following components: C: 0.12%, Si: 0.25%, Mn: 1.44%, P: 0.011%, S: 0.007%, Al: 0.034%, Mo: 0.22%, Cr: 0.37%, Nb: 0.020%, N: 0.0030%, B: 0.0017%, and the balance is Fe and unavoidable impurities.

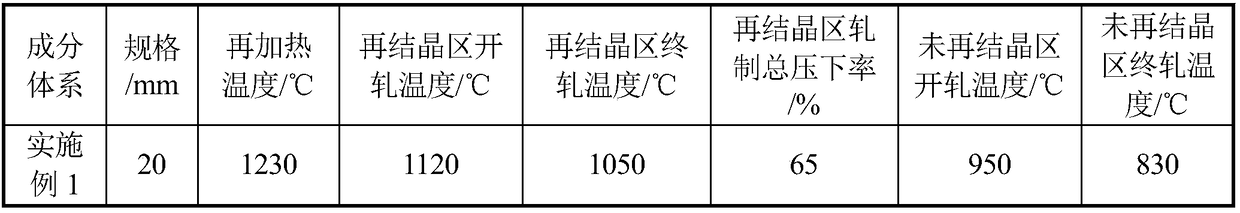

[0031] The production process route of quenched and tempered steel in this embodiment includes top-bottom combined blowing converter, LF refining, VD degassing, wide slab continuous casting, steckel mill rolling, two-phase zone quenching, and tempering. Among them, the rolling process system is show...

Embodiment 2

[0032] Table 1 The rolling process system of the 20mm high-strength steel plate in this embodiment

[0033]

[0034] Table 2 Quenching process system of the 20mm high-strength steel plate in the two-phase zone of this embodiment

[0035] Ingredient system

Thickness / mm

Reheating temperature / ℃

heating coefficient

Holding time / min

Example 1

20

870

1.5

15

[0036] Table 3 The process system of tempering after quenching in the two-phase zone of the 20mm high-strength steel plate in this example

[0037] Ingredient system

Thickness / mm

heating coefficient

Holding time / min

Example 1

20

590

3

15

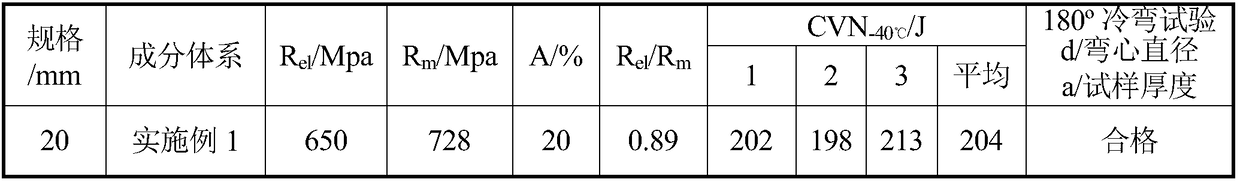

[0038] The performance indexes of the steel plates produced according to the steps of this embodiment are shown in Table 4.

[0039] Table 4 Quenching and tempering properties of the 20mm high-strength steel plate in this embodiment in the two-phase region

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com