Curved bridge step pushing method

A curved bridge and jacking technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unsatisfactory, low efficiency, and inability to run at a loading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

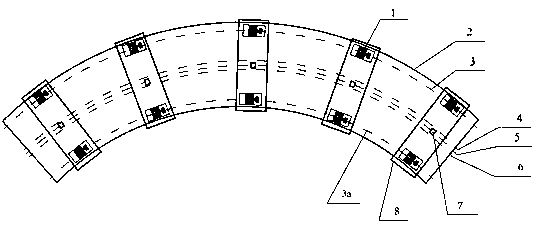

[0022] The present invention comprises steps:

[0023] (1) Calculation steps: According to the curvature and radius of the main girder’s pushing route, calculate the total distance of the outer pushing and the total distance of the inner pushing respectively, determine the speed ratio of the pushing on both sides according to the distance, and determine the pushing on both sides according to the speed ratio The oil inlet flow ratio of the jack;

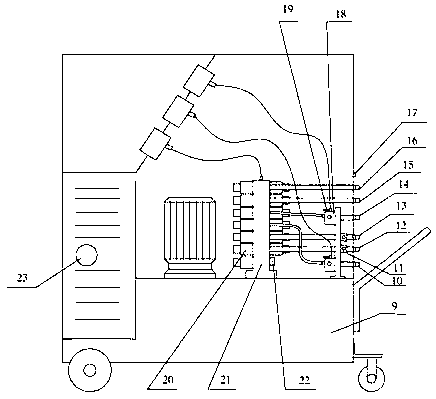

[0024] (2) Control center parameter setting steps: set in the control center including the oil inlet flow ratio of the jacks on both sides, the maximum allowable deviation distance of the main girder, and the relevant parameters of jacking, pushing, and deviation correction. After the setting is completed start the device;

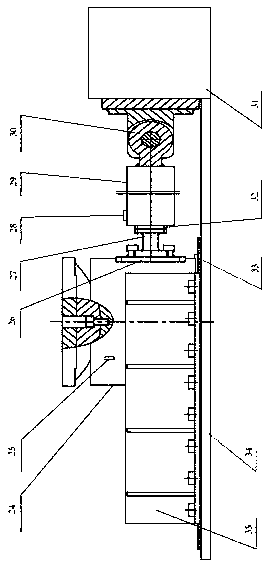

[0025] (3) Arrangement steps of jacking units: set multiple groups of jacking units on both sides of the pier inside and outside. , arranged in the center along the tangential direction;

[0026] (4) Steps for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com