Horizontal well refracturing device and method based on open hole preset pipe string completion

A technology for refracturing and horizontal wells, which is applied in wellbore/well components, earthwork drilling and production, and production fluids, etc. It can solve the difficulty of refracturing reconstruction, open hole prefabricated string refracturing reconstruction has not yet appeared, fracturing tools It is difficult to run in and other problems, so as to reduce the risk of resistance, prolong the life of the oil well, and increase the production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

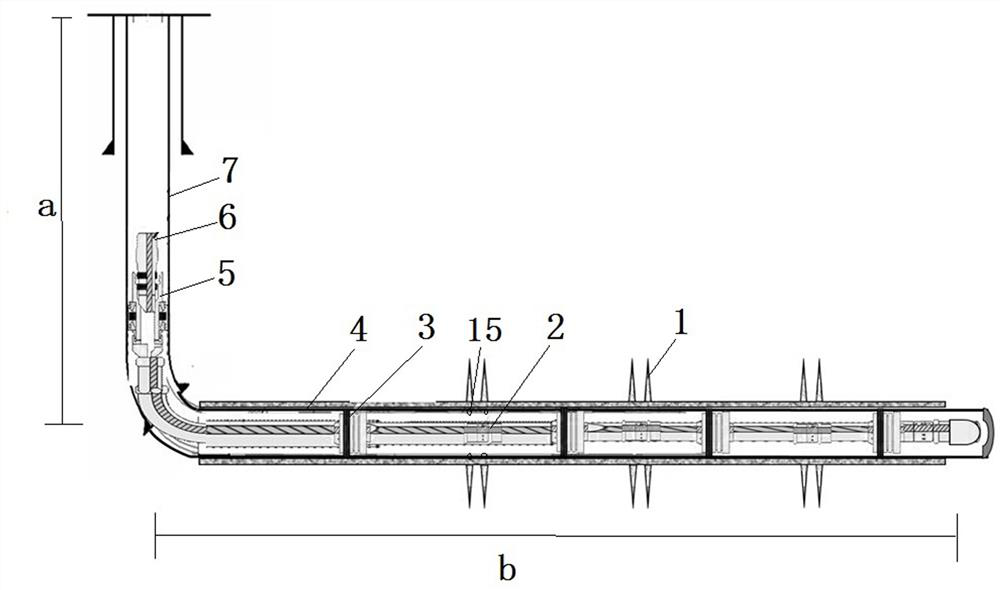

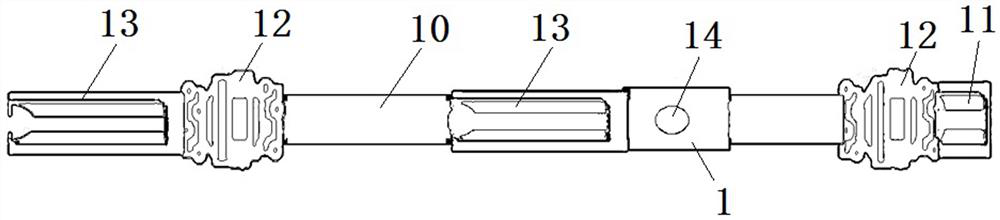

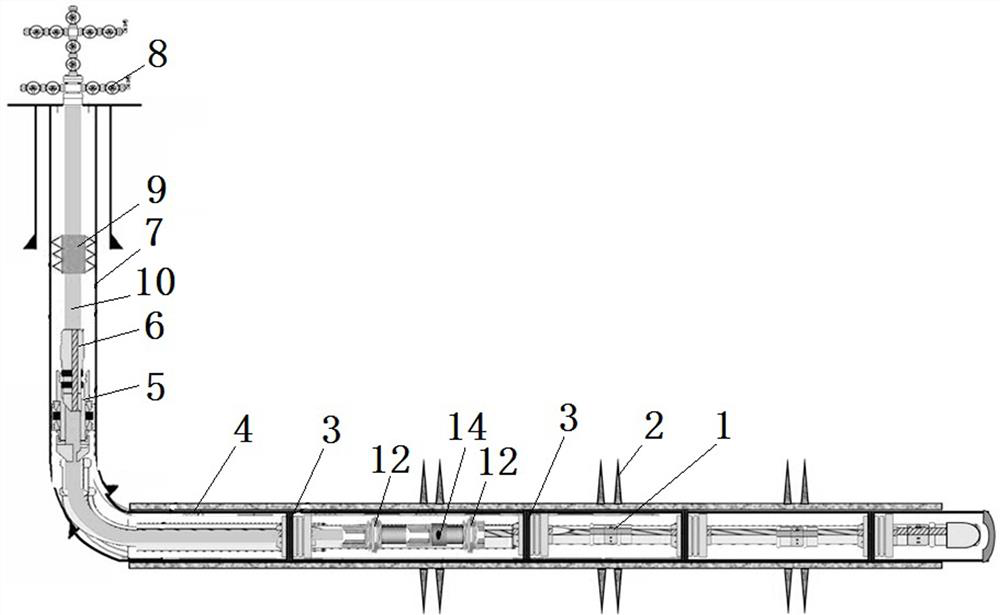

[0024] The specific embodiment of the horizontal well refracturing device based on the completion of the open hole preset pipe string of the present invention is as follows: Figure 2 to Figure 4 As shown, the horizontal well refracturing device based on the completion of the open-hole preset pipe string includes a tubing 10, an expandable packer 3 and a ball sliding sleeve 1. The gap between the outer circumference of 10 and the inner circumference of the tail pipe is sealed by dropping low-density balls and blocking the outlet of the oil pipe 10 under the impact of the high-pressure liquid in the oil pipe 10, opening the liquid outlet 14 of the ball-throwing sleeve 1, and under the impact of the high-pressure oil The secondary fracturing of rock formations can be realized in order to increase production.

[0025] Such as figure 2 As shown, the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com