220t/h-grade circulating fluidized bed boiler with medium-temperature and medium-pressure parameters

A circulating fluidized bed and boiler technology, applied in fluidized bed boilers, fluidized bed combustion equipment, steam boilers, etc., can solve the problems of unreasonable and unsatisfactory setting of tail flue economizer and low temperature superheater, etc. Achieve the effects of easy maintenance and maintenance, stable operation, and widening the development path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

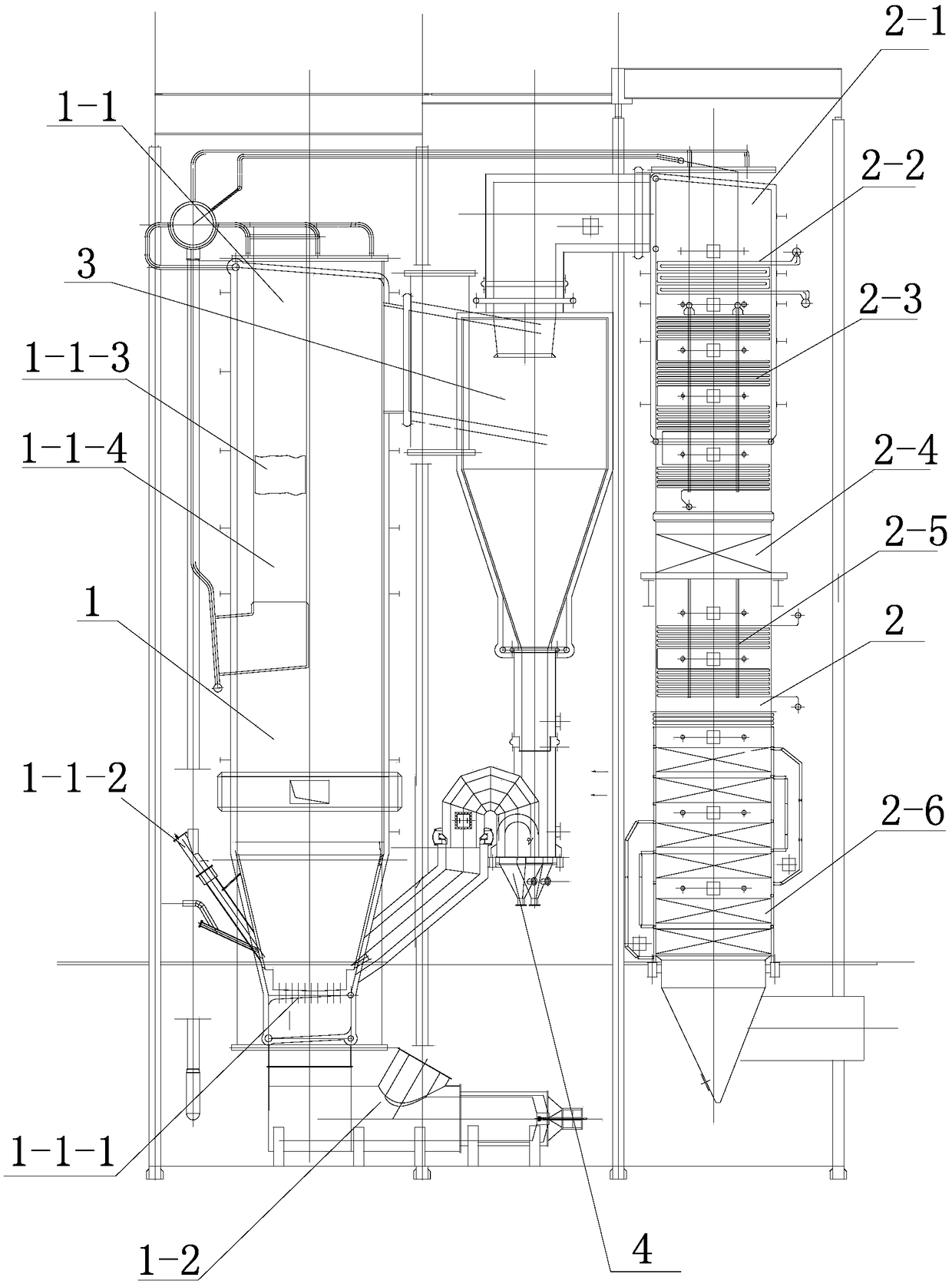

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, a 220t / h circulating fluidized bed boiler adopting medium temperature and medium pressure parameters in this embodiment, which includes a boiler front shaft 1, a boiler tail shaft 2 and a cyclone separator arranged in an M shape as a whole 3,

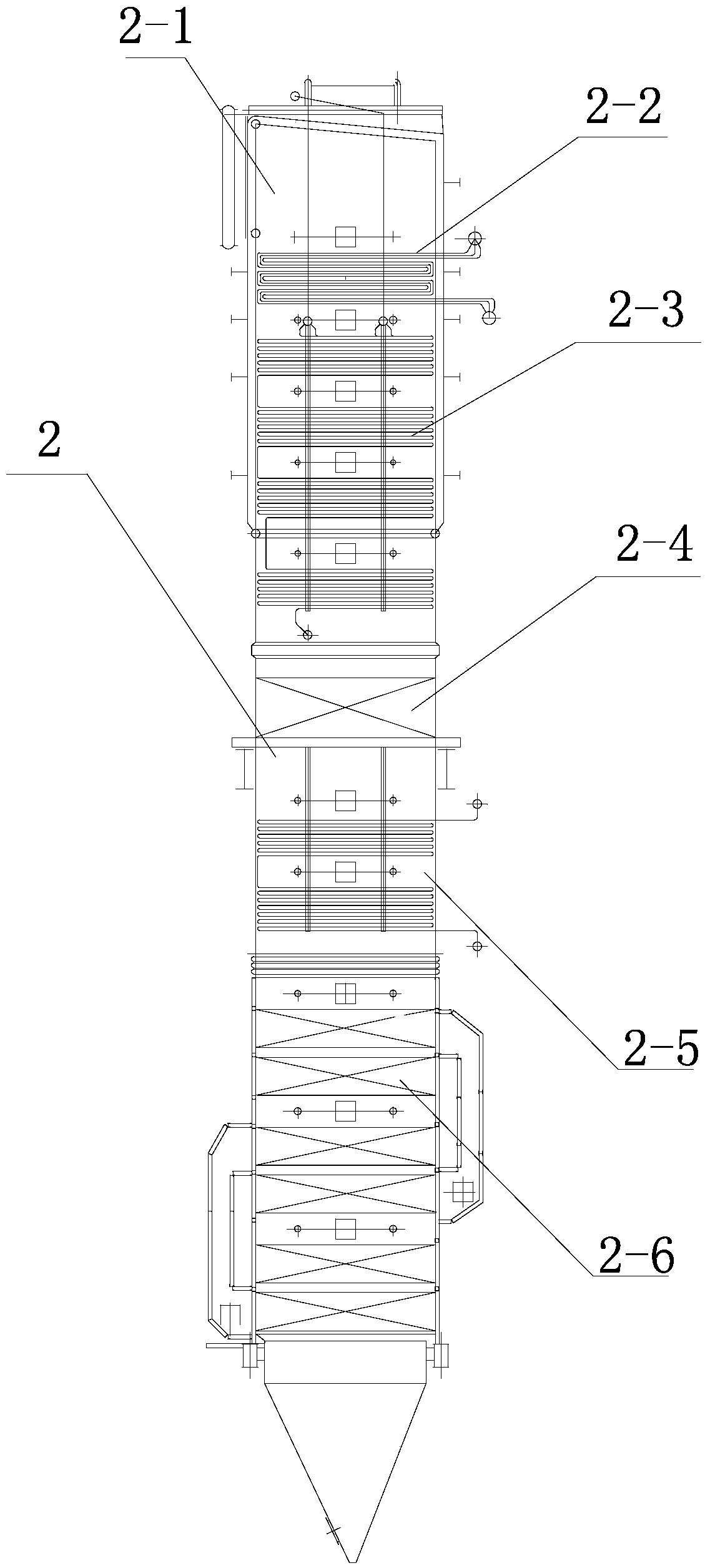

[0016] Boiler front shaft 1 is a general crane structure, and the outer walls around shaft 1 are membrane water-cooled walls. Boiler tail shaft 2 is also a general crane structure. The flue at the top of boiler front shaft 1 passes through cyclone separator 3 and boiler tail shaft 2. The flue at the top is connected, and the lower part of the cyclone separator 3 is connected to the return device 4 and the ash cooler. The front shaft 1 of the boiler adopts a membrane wall with insulation and an external metal guard plate, and the tail shaft 2 of the boiler adopts a membrane type Insulation is added to the wall, and the shaft 2 at the rear of the boiler i...

specific Embodiment approach 2

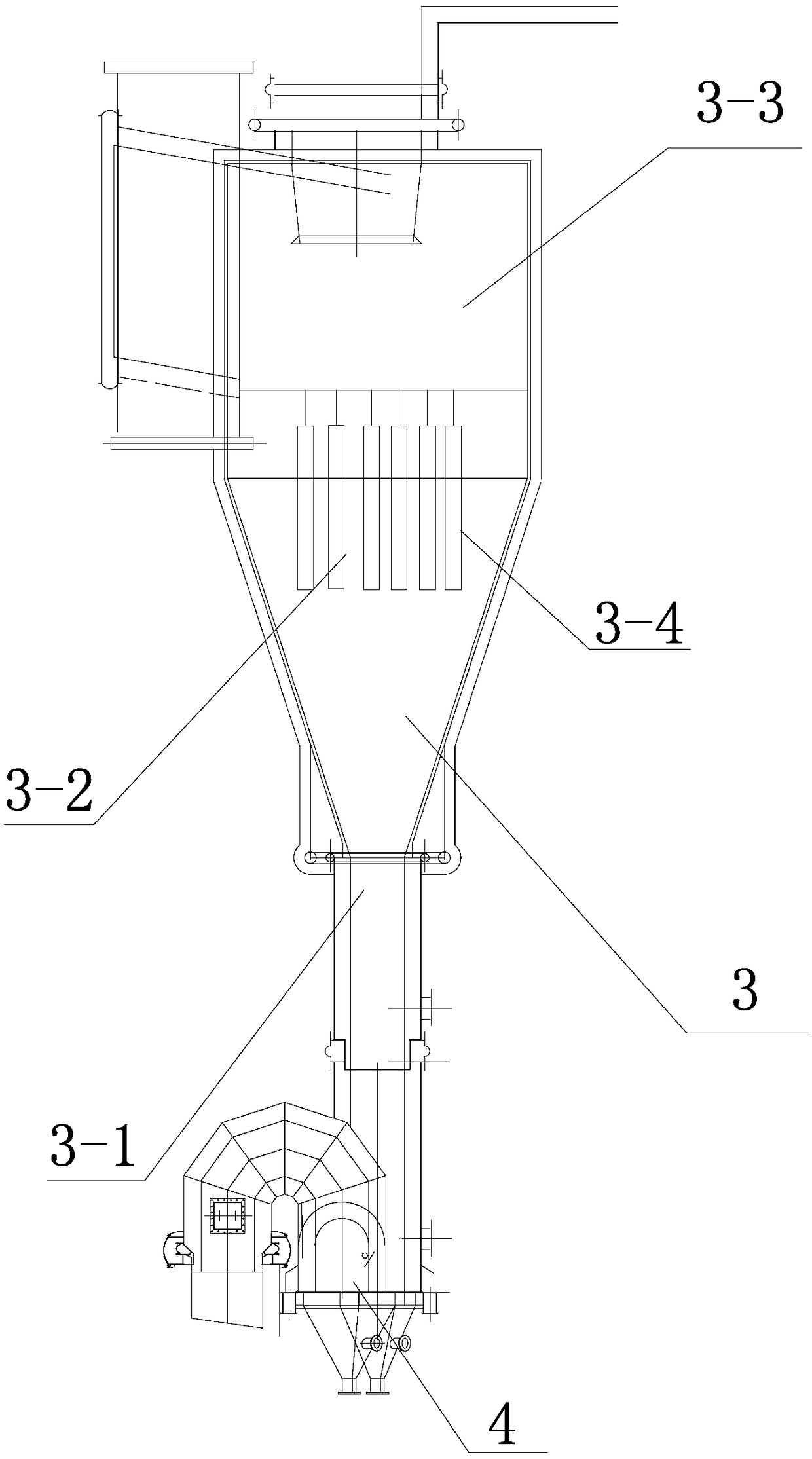

[0019] Specific implementation mode two: combination figure 1 Describe this embodiment, a 220t / h circulating fluidized bed boiler adopting medium temperature and medium pressure parameters in this embodiment, the cyclone separator 3 adopts a vertical conical cylinder structure, and the internal vertical direction is respectively from bottom to top Return material standpipe area 3-1, cyclone separation area 3-2, clean room area 3-3, said cyclone separation area 3-2 is provided with a plurality of cyclone separator tubes 3-4, a plurality of cyclone separator tubes 3- 4 is hoisted inside the cyclone separator 3. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 Describe this embodiment, a 220t / h circulating fluidized bed boiler adopting medium temperature and medium pressure parameters in this embodiment, the low-temperature superheater 2-2 is a convection type superheater, and the low-temperature superheater 2-2 is composed of a large number of It consists of parallel parallel serpentine tubes, the outer diameter of the serpentine tube is 32-44mm, the wall thickness of the serpentine tube is 3-7mm, and the material of the serpentine tube is carbon steel pipe. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com