Copper binding wire tension tester with good fixing effect

A tensile testing machine and copper-clad wire technology, applied in the field of physical testing, can solve the problems of poor fixing effect of copper-clad wire, inconvenient movement and inability to adjust the length of a rotating frame, etc., to save labor intensity, improve anti-skid effect, and improve clamping The effect of tight fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

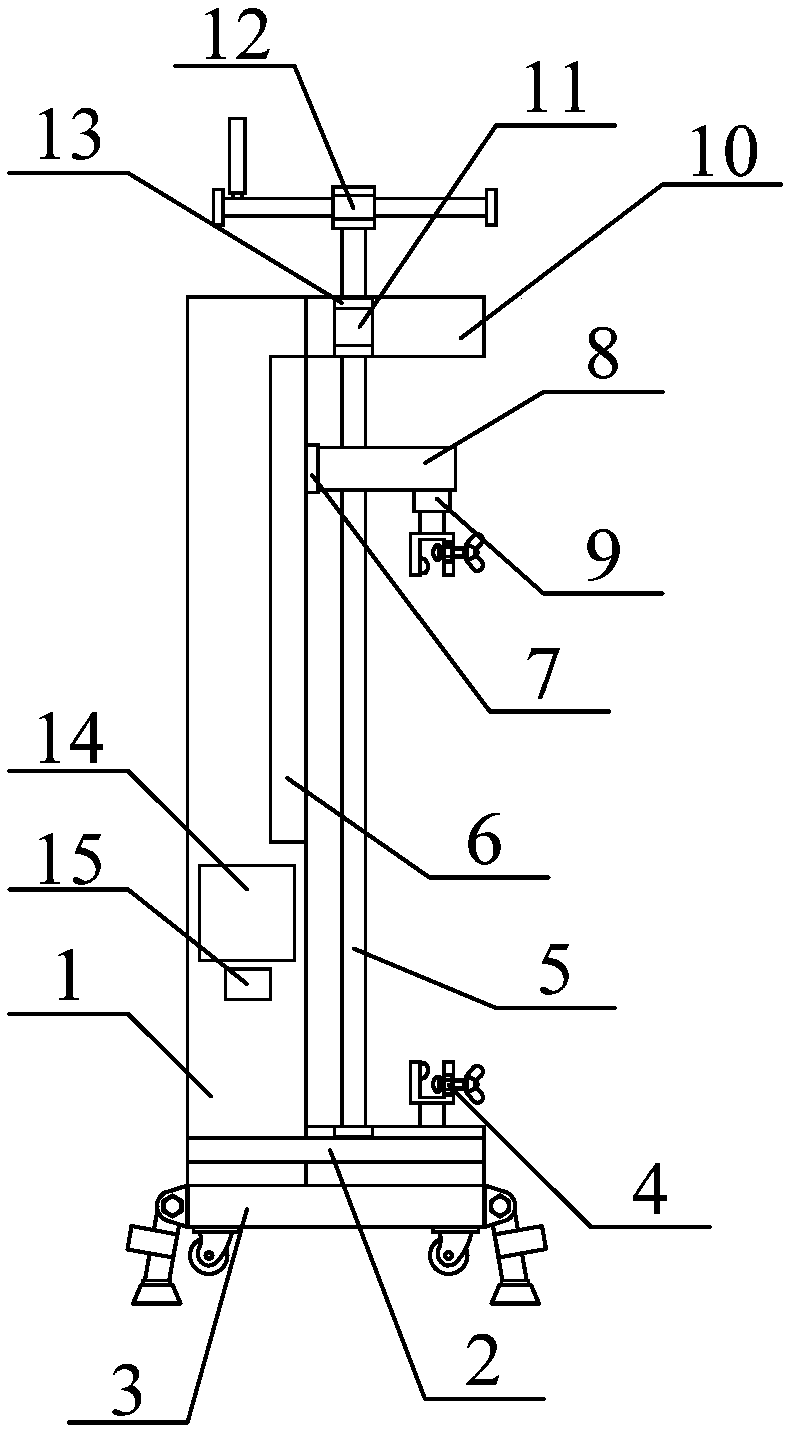

[0035] as attached figure 1 And attached figure 2 shown

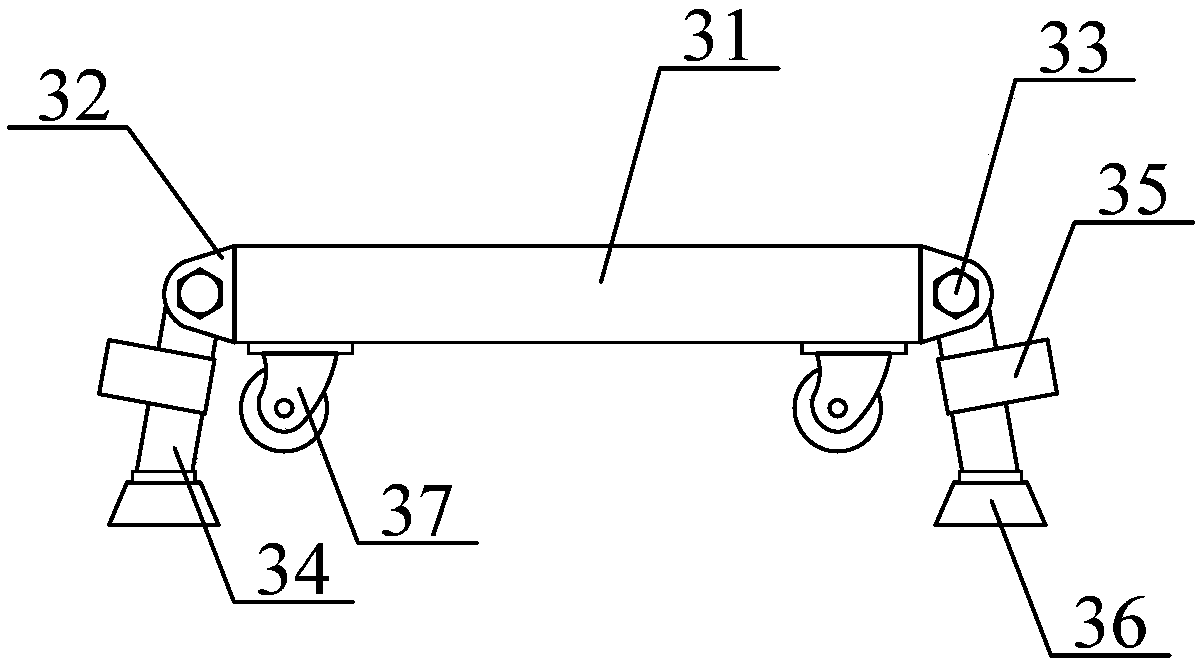

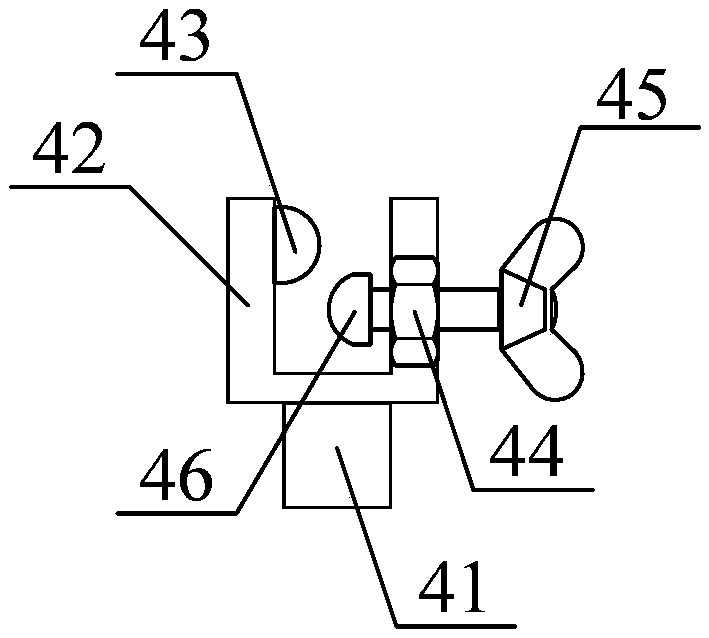

[0036]The invention provides a copper-clad wire tensile testing machine with good fixing effect, which includes a longitudinal installation frame 1, a Velcro buckle 2, an adjustable movable fixing frame structure 3, a copper-clad wire clamping and reinforcing seat structure 4, and a lead screw 5. Longitudinal U-shaped chute 6, slider 7, connecting frame 8 with internal thread, tension sensor 9, horizontal fixing plate 10, longitudinal positioning tube 11, manual rotating frame structure 12, ball bearing 13, display screen 14 and micro PLC15, The Velcro buckle 2 is glued laterally on the lower outside of the longitudinal installation frame 1 and the lateral fixing plate 10; the adjustable movable fixing frame structure 3 is installed on the lower part of the longitudinal installation frame 1 and the lateral fixing plate 10; The copper-clad wire clamping reinforcement seat structure 4 is respectively installed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com