Heat preservation cover and method of using same to shorten filter paper ashing time in gravimetric analysis method

A technology of thermal insulation cover and filter paper, applied in the field of chemical analysis, can solve the problems of low ashing efficiency, inconvenient observation of ashing conditions, long time required for ashing of filter paper, etc., so as to improve heating efficiency, shorten ashing time, and avoid filter paper burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

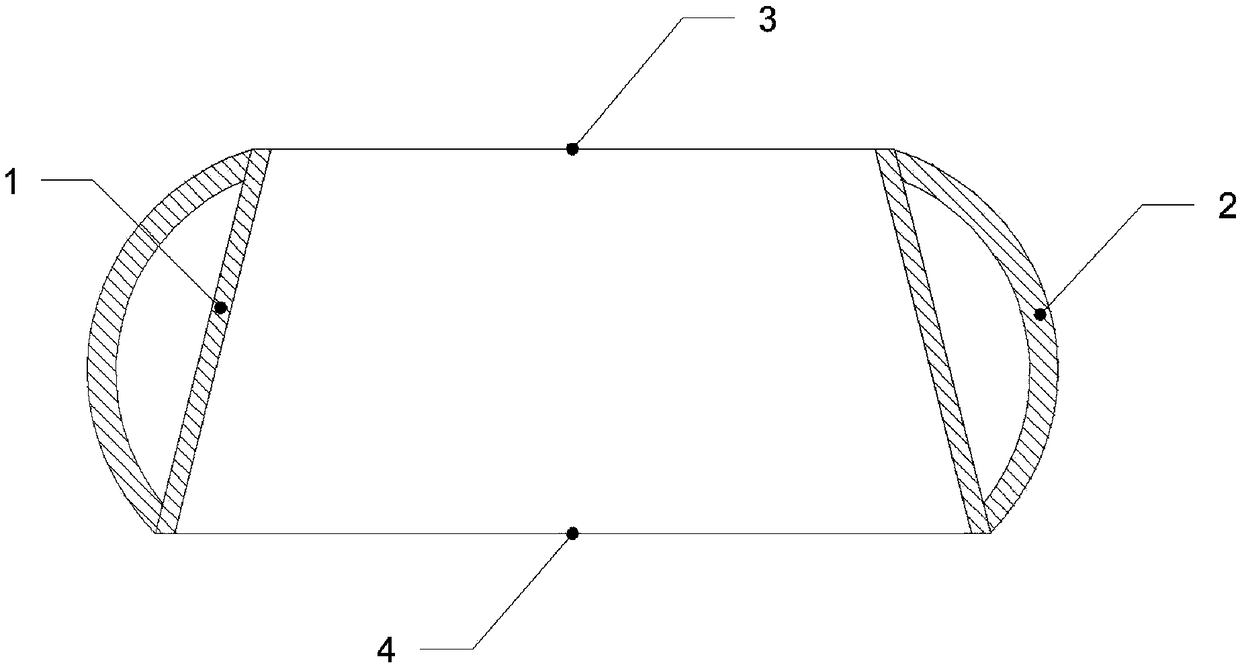

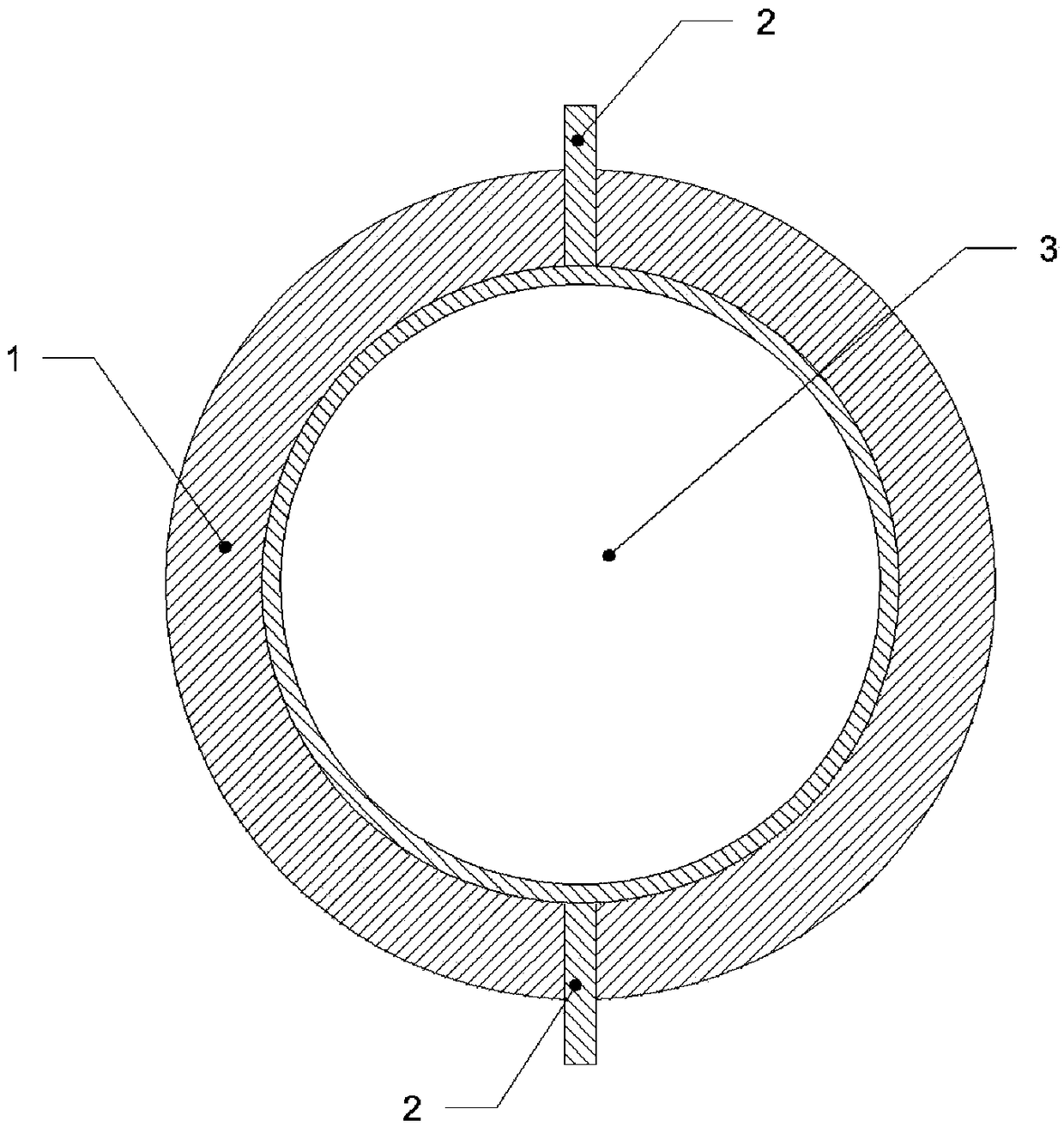

[0052] This embodiment provides a heat preservation cover, its front view and top view are as follows figure 1 and figure 2 As shown, the heat preservation cover includes a cover body 1, the upper and lower ends of the cover body are set as hollow, one end is provided with a first hole 3, and the other end is provided with a second hole 4, and the area of the first hole 3 is smaller than that of the second hole 4, the cover body is also provided with a handle 2.

[0053] The cover 1 is in the shape of a truncated cone, with a height of 120 mm and a wall thickness of 6 mm; two handles 2 are symmetrically distributed on the cover, and the thickness of the handle is 10 mm; the inner diameter of the first hole 3 is 188 mm, the second The outer diameter of the first hole 3 is 200mm, the inner diameter of the second hole 4 is 248mm, and the outer diameter of the second hole 4 is 260mm.

[0054] The cover body 1 is made of quartz and feldspar mixed and then fired.

[0055] A me...

Embodiment 2

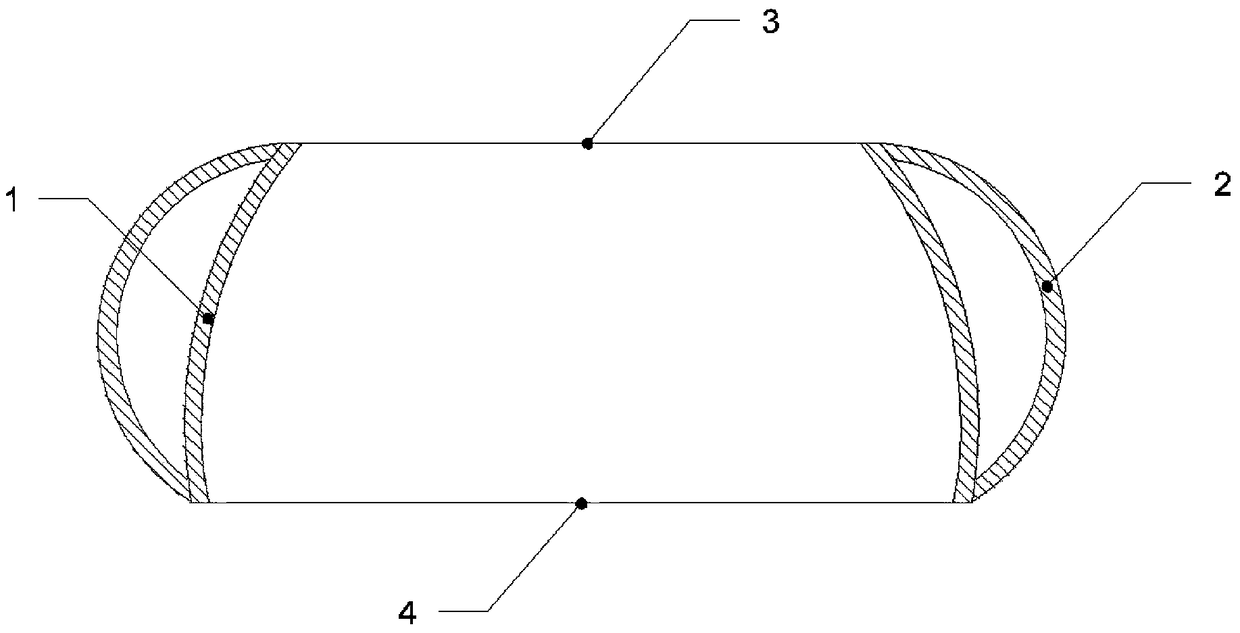

[0059] This embodiment provides a heat preservation cover, including a cover body 1, the upper and lower ends of the cover body are set as hollow, one end is provided with a first hole 3, and the other end is provided with a second hole 4, the area of the first hole 3 is Smaller than the area of the second hole 4, a handle 2 is also provided on the cover.

[0060] The cover 1 is in the shape of a truncated cone, with a height of 100 mm and a wall thickness of 5 mm; two handles 2 are symmetrically distributed on the cover, and the thickness of the handle is 5 mm; the inner diameter of the first hole 3 is 150 mm, and the second The outer diameter of the first hole 3 is 160 mm, the inner diameter of the second hole 4 is 200 mm, and the outer diameter of the second hole 4 is 210 mm.

[0061] The cover body 1 is made by mixing quartz and clay and then firing.

[0062] The method for shortening the filter paper ashing time in the gravimetric method using the above-mentioned hea...

Embodiment 3

[0066] This embodiment provides a heat preservation cover, including a cover body 1, the upper and lower ends of the cover body are set as hollow, one end is provided with a first hole 3, and the other end is provided with a second hole 4, the area of the first hole 3 is Smaller than the area of the second hole 4, a handle 2 is also provided on the cover.

[0067] The cover 1 is in the shape of a truncated cone, with a height of 200 mm and a wall thickness of 10 mm; two handles 2 are symmetrically distributed on the cover, and the thickness of the handle is 15 mm; the inner diameter of the first hole 3 is 250 mm, the second The outer diameter of the first hole 3 is 270mm, the inner diameter of the second hole 4 is 300mm, and the outer diameter of the second hole 4 is 320mm.

[0068] The cover body 1 is made by mixing feldspar and clay and then firing.

[0069] The method for shortening the filter paper ashing time in the gravimetric method using the above-mentioned heat p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com