Ashing assistant and method for detecting ash of bioactive pectin through the same

A technology of ashing aids and biological activity, which is applied in the field of detection of bioactive pectin ash and ashing aids. It can solve the problems of affecting the accuracy of ash content and low accuracy of ashing results, so as to improve the accuracy and shorten the ashing time. time, efficient ashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Fire the porcelain crucible, after cooling, weigh it accurately, repeat the firing until the difference between the two weighings is not more than 0.5 mg, and weigh the mass of the porcelain crucible as m.

[0074] According to the nitric acid of 55wt%, the hydrogen peroxide of 6wt%, the water preparation ashing aid of 39wt%.

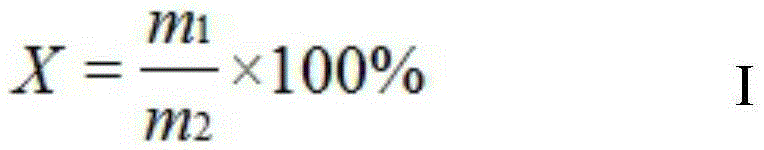

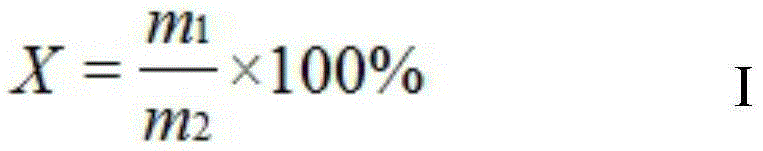

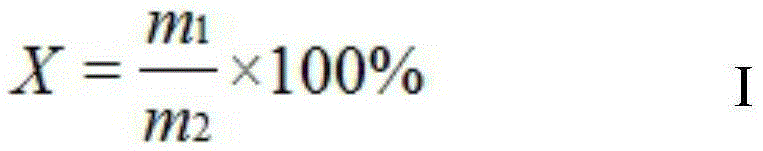

[0075] Accurately weigh 0.5g of bioactive pectin in a 50mL porcelain crucible, and weigh the quality of the porcelain crucible and bioactive pectin as M 2 , after carbonization on a heating plate at 250°C for 2h, it was moved into a muffle furnace for ashing at 500°C for 4h. After cooling for 30 minutes, add 8 mL of ashing aid into the porcelain crucible, and heat until the ashing aid is completely volatilized. Move the resulting product back into the muffle furnace with the porcelain crucible and continue ashing for 4 hours. Repeat the operation 4 times in total. The product obtained has a constant weight, which is the ash content in the bioact...

Embodiment 2

[0078] Fire the porcelain crucible, after cooling, weigh it accurately, repeat the firing until the difference between the two weighings is not more than 0.5 mg, and weigh the mass of the porcelain crucible as m.

[0079] Prepare the ashing aid by 30wt% nitric acid, 15wt% hydrogen peroxide, and 55wt% water.

[0080] Accurately weigh 1.0g of bioactive pectin in a 50mL porcelain crucible, and weigh the quality of the porcelain crucible and bioactive pectin as M 2 , After carbonization on a heating plate at 350°C for 4h, it was moved into a muffle furnace for ashing at 500°C for 5h. After cooling for 30 minutes, add 8 mL of ashing aid into the porcelain crucible, and slowly heat until the ashing aid is completely volatilized. Move the resulting product back into the muffle furnace with the porcelain crucible to continue ashing for 4 hours. Repeat the operation 5 times in total. The product obtained has a constant weight, which is the ash content in the bioactive pectin. Weigh th...

Embodiment 3

[0083] Fire the porcelain crucible, after cooling, weigh it accurately, repeat the firing until the difference between the two weighings is not more than 0.5 mg, and weigh the mass of the porcelain crucible as m.

[0084] Prepare the ashing aid by 13wt% nitric acid, 24wt% hydrogen peroxide, and 63wt% water.

[0085] Accurately weigh 1.2g of bioactive pectin in a 50mL porcelain crucible, and weigh the quality of the porcelain crucible and bioactive pectin as M 2 , after carbonization on a heating plate at 300°C for 3h, it was moved into a muffle furnace for ashing at 600°C for 5h. After cooling for 40 minutes, add 10 mL of ashing aid into the porcelain crucible, and slowly heat until the ashing aid is completely volatilized. Move the obtained product back into the muffle furnace with the porcelain crucible and continue ashing for 5 hours. Repeat the operation twice in total. The obtained product has a constant weight, which is the ash content in the bioactive pectin. Weigh the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com