Reliability evaluation method of rocket engine nozzle movable joint structure

A rocket engine and living connection technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high test cost, unfavorable atmospheric environment protection, and long test cycle, so as to shorten the development cycle and reduce high-altitude The effect of simulating the number of test runs and reducing the cost of reliability test verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be pointed out that for those of ordinary skill in the art, a number of modifications and improvements can be made without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

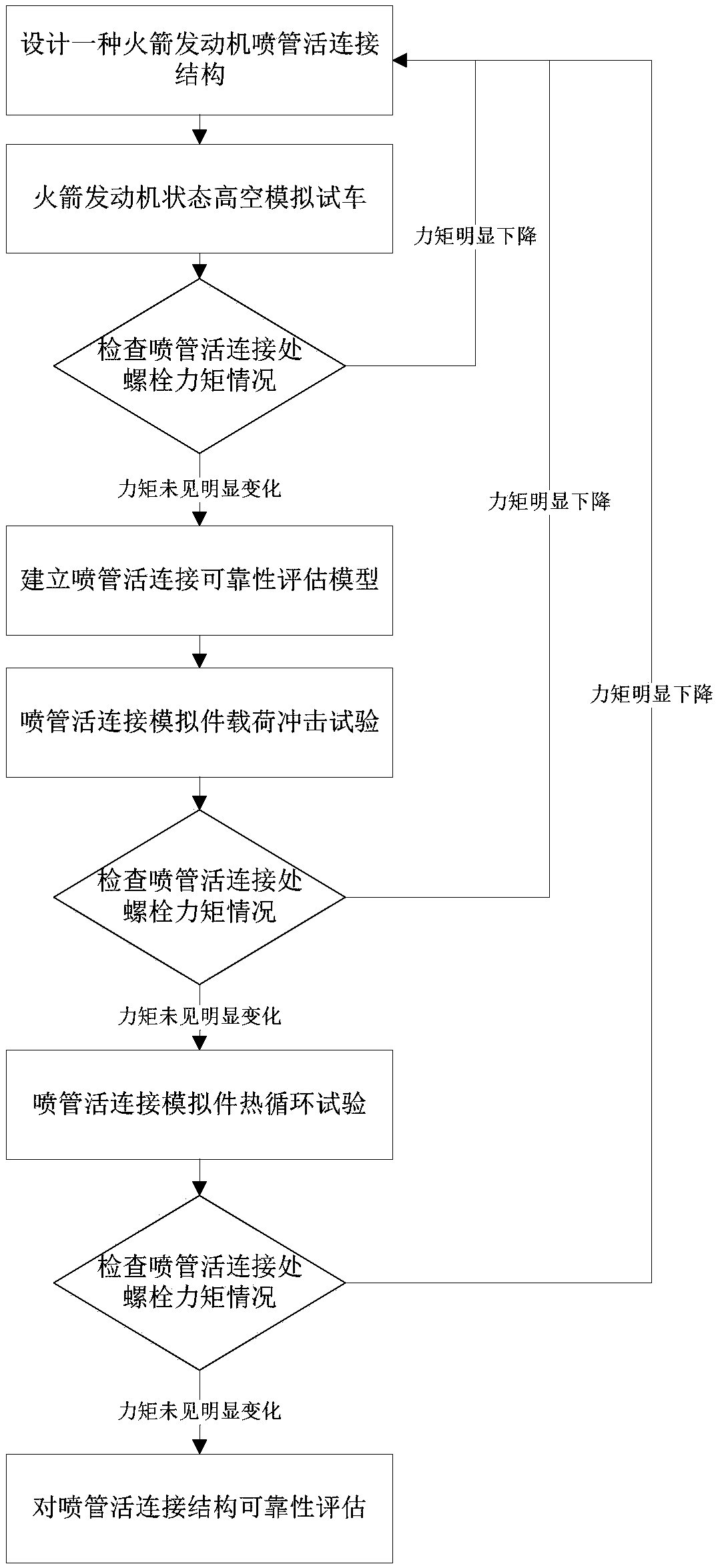

[0022] figure 1 Operation flow chart for the reliability assessment method of the live connection structure of the rocket engine nozzle, now combined figure 1 Describe the steps in a specific implementation case of the present invention.

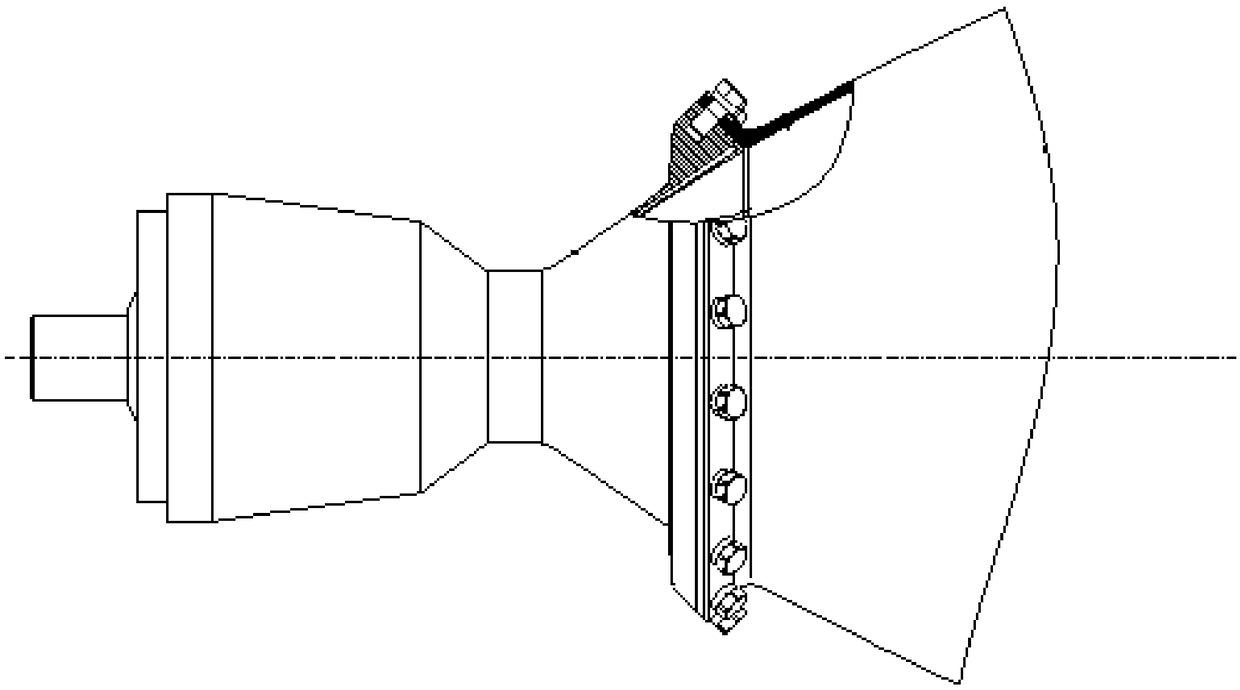

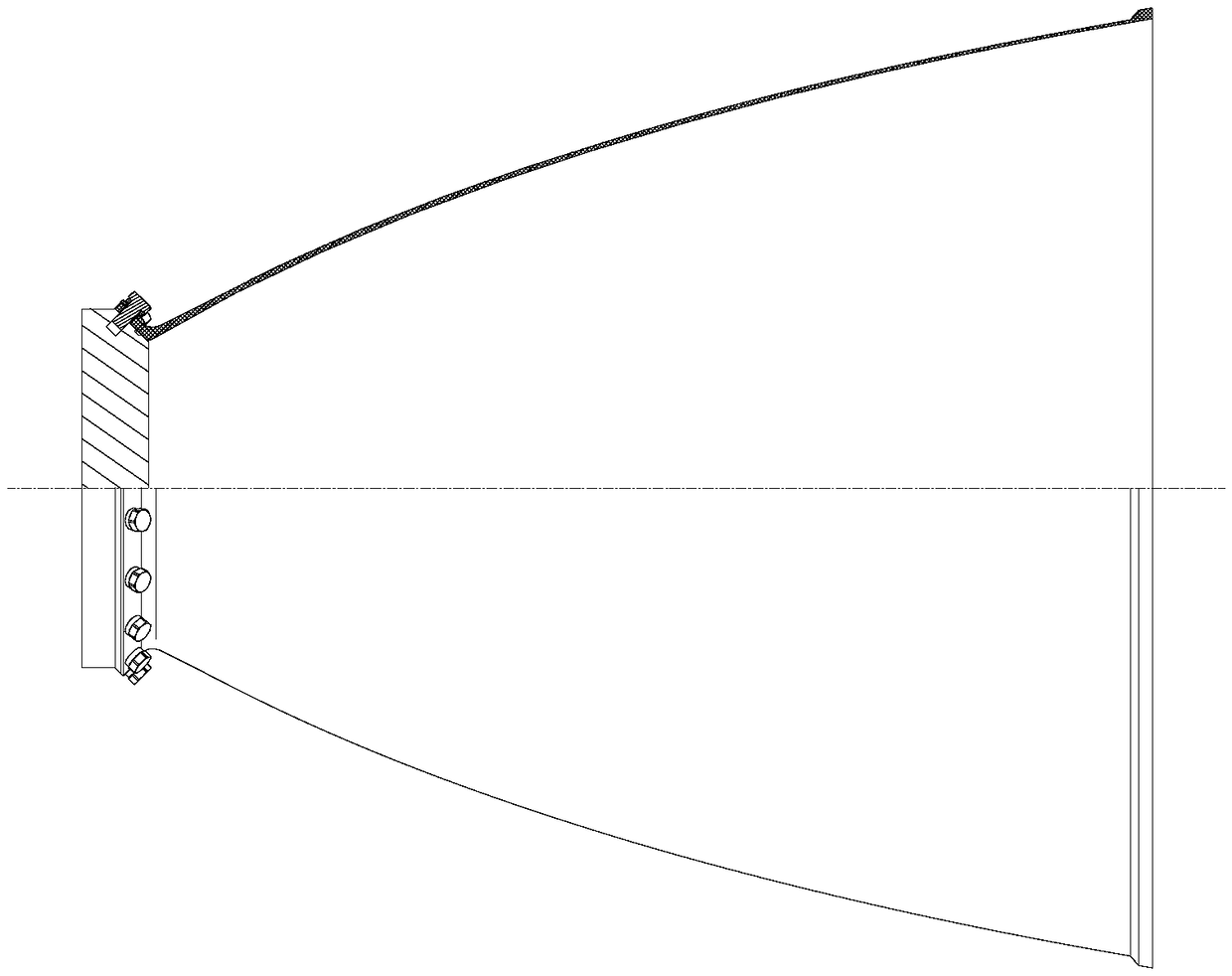

[0023] Step 1. Design an active connection structure of rocket engine nozzle; see figure 1 , Flange connection is adopted, multiple connecting bolts are evenly distributed, and the tightening torque of the bolts is strictly controlled to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com