A harmonic reducer flexspline structure integrated optimization method based on a gradient descent method

A technology of harmonic reducer and gradient descent method, which is applied in design optimization/simulation, instrumentation, geometric CAD, etc., to achieve the effects of increasing convergence speed, improving accuracy, and simplifying calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation of the present invention will be further described below in conjunction with the drawings and embodiments.

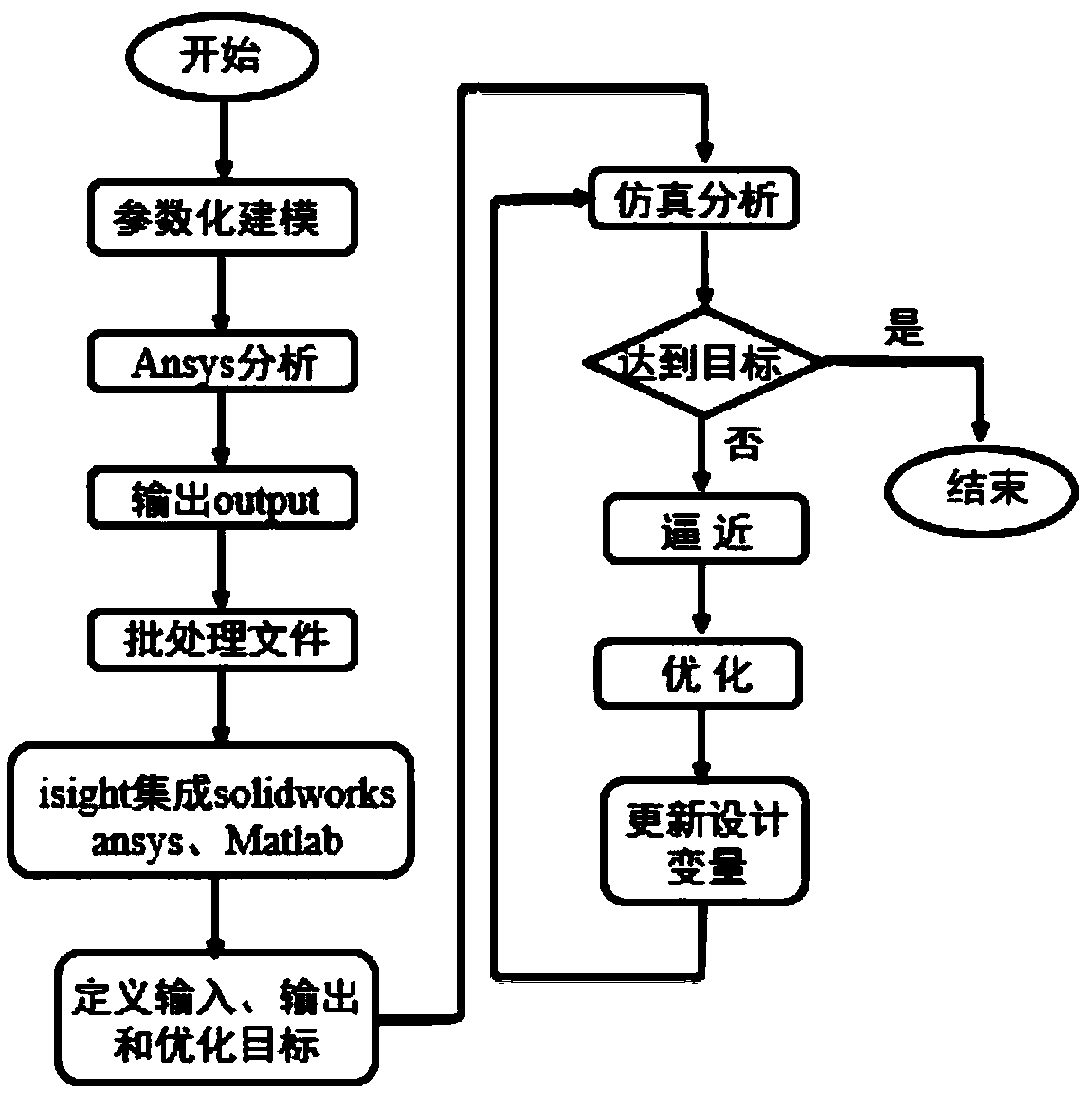

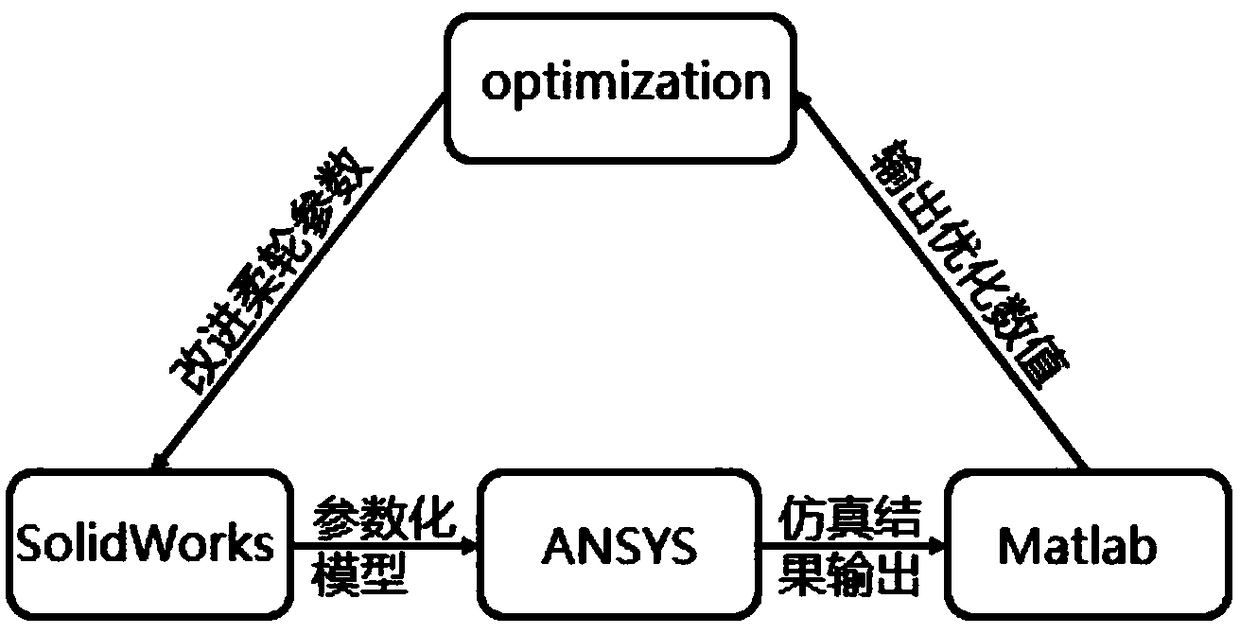

[0048] Such as figure 1 Shown is the schematic diagram of the optimization process of the harmonic reducer flexible spline proposed by the present invention, the parameterized three-dimensional model of the harmonic reducer flexible spline, rigid spline, and wave generator is established, the .igs file is generated, and the parameterized model is passed through ANSYSAPDL Conduct contact simulation analysis, input settings for optimization in SolidWorks components, set the range of optimization variables, set optimization constraints and objective functions in ANSYS and MATLAB components, use Isight software to integrate into SolidWorks, ANSYS, and MATLAB using gradient The descending optimization algorithm (LSGRG) is used to optimize the structure of the flexspline. Finally, the structural parameters of the flexspline satisfying the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com