A molten salt fuel multi-stack system

A molten salt and fuel technology, applied in the field of nuclear energy utilization, to achieve the effect of realizing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment takes a molten salt fuel multi-stack system with thermal power of 2.0GW+1.0GW as an example.

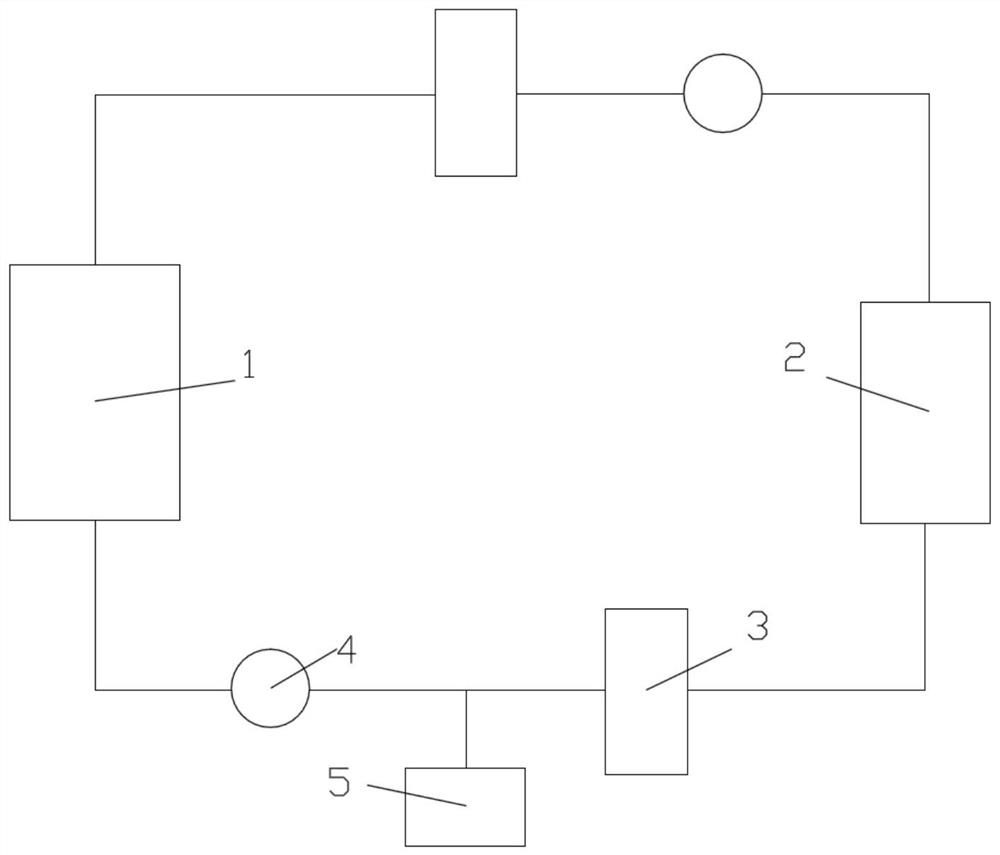

[0045] Such as figure 1 The tandem molten salt fuel multi-reactor system shown, the molten salt fuel multi-reactor system includes 1 type I reactor module 1, 1 type II reactor module 2, 2 heat exchange modules 3, 2 pump modules 4 and 1 fuel processing module 5. One type I reactor module 1 and one type II reactor module 2 use the same molten salt fuel and flow in different modules, that is, the molten salt fuel flowing out of type I reactor module 1 directly flows to the next A Category II reactor module 2. Class I reactor modules are primarily used for production capacity. Class II reactor modules are primarily used for breeding.

[0046] Type I reactor module 1 with a thermal power of 2.0GW and a conversion ratio of 0.9. The radius of the active zone of the core is 2.5m, and the height is 5.0m; the proportion of the molten salt volume to the total volume i...

Embodiment 2

[0050] This embodiment takes a molten salt fuel multi-stack system with thermal power of 2.0GW+1.0GW as an example.

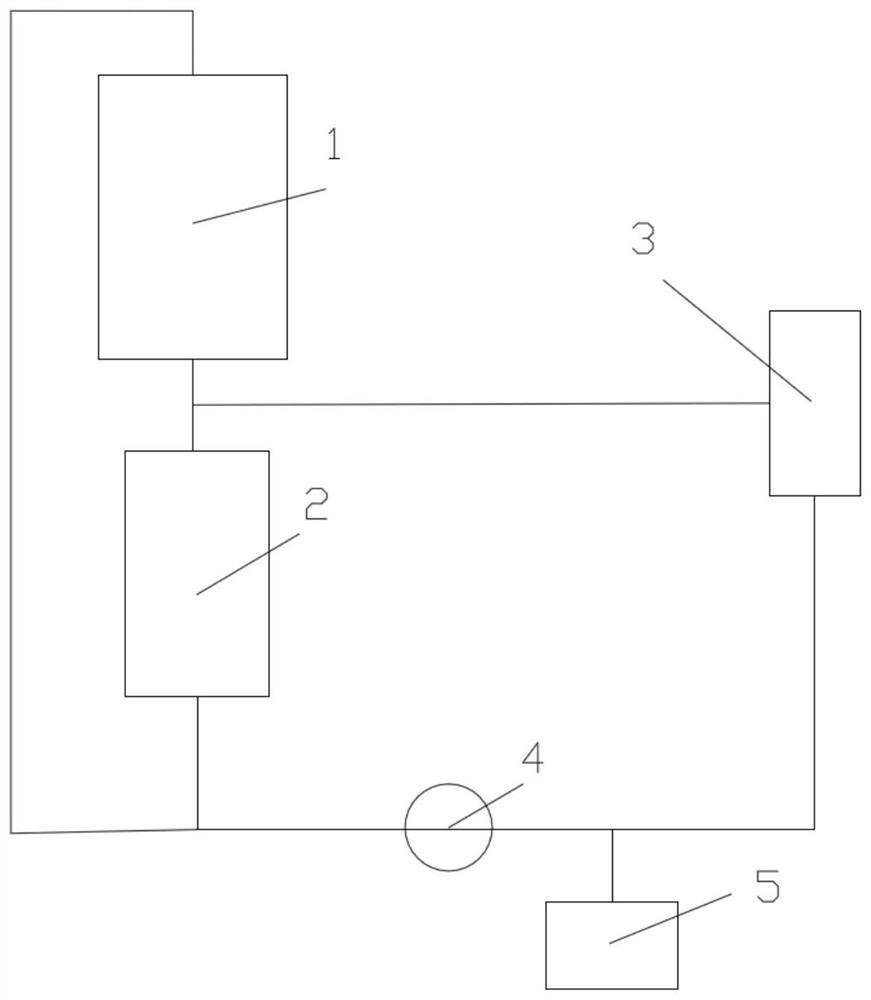

[0051] Such as figure 2 The parallel molten salt fuel multi-reactor system shown, the molten salt fuel multi-reactor system includes a type I reactor module 1, a type II reactor module 2, a heat exchange module 3, a pump module 4 and 1 Fuel processing module 5. One type I reactor module 1 and one type II reactor module 2 use the same molten salt fuel and flow in different modules, that is, enter type I reactor module 1 and type II reactor module 2 respectively , pass through the respective reactor modules, flow out and aggregate, and then flow into the heat exchange module 3 . Class I reactor modules are primarily used for production capacity. Class II reactor modules are primarily used for breeding.

[0052] Type I reactor module 1 with a thermal power of 2.0GW and a conversion ratio of 0.9. The radius of the active zone of the core is 2.5m, and the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com