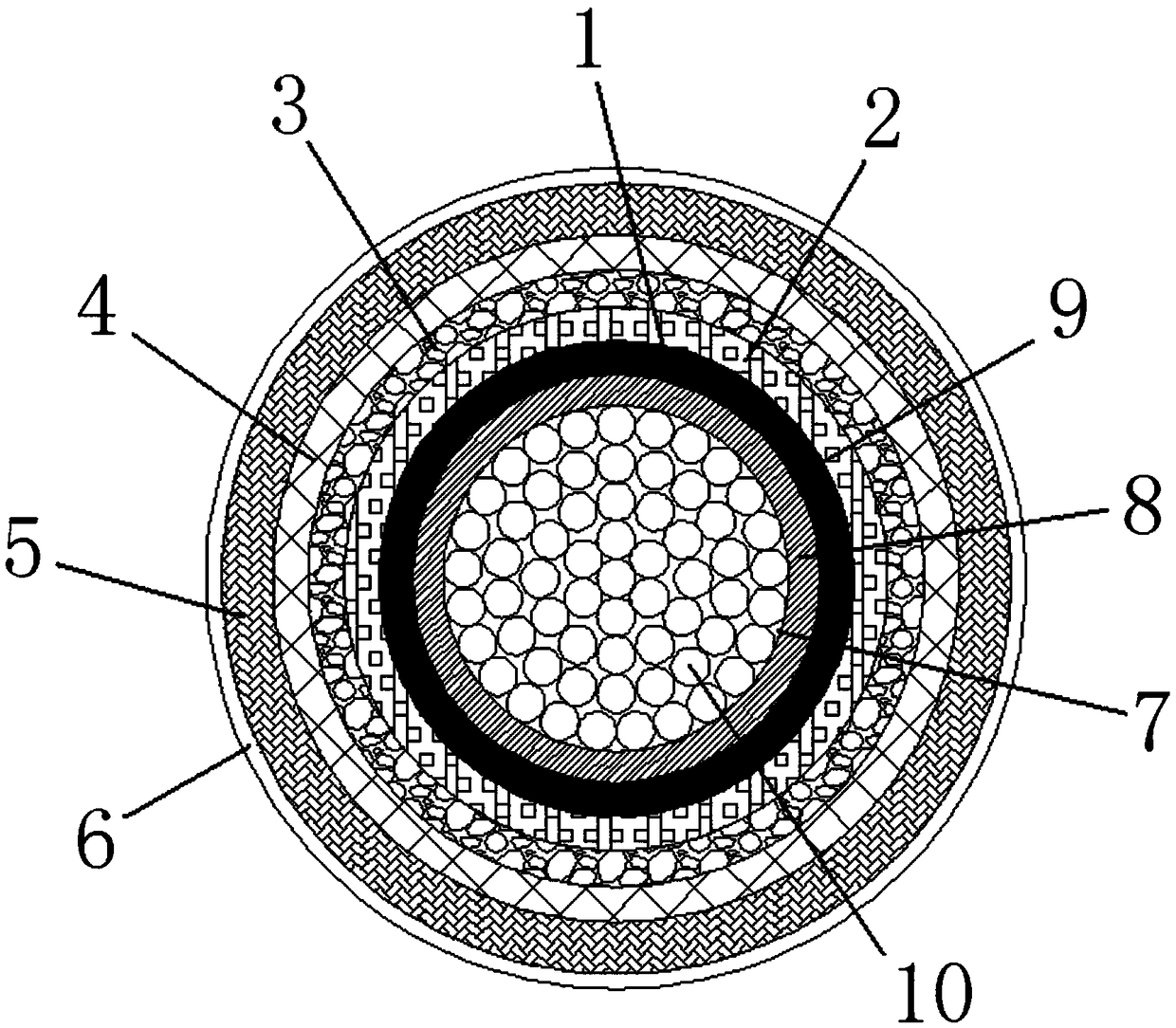

A low-temperature and torsion-resistant wind power generation cable and a preparation method thereof

A torsion-resistant and low-temperature-resistant technology, which is applied in the direction of cable/conductor manufacturing, cable insulation, conductor/cable insulation, etc., can solve the problems that cables are easily corroded by acid and alkali, cables are easy to be pulled off, and cables are broken. Enhanced pullability, not easy to be pulled off, and the effect of reducing line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

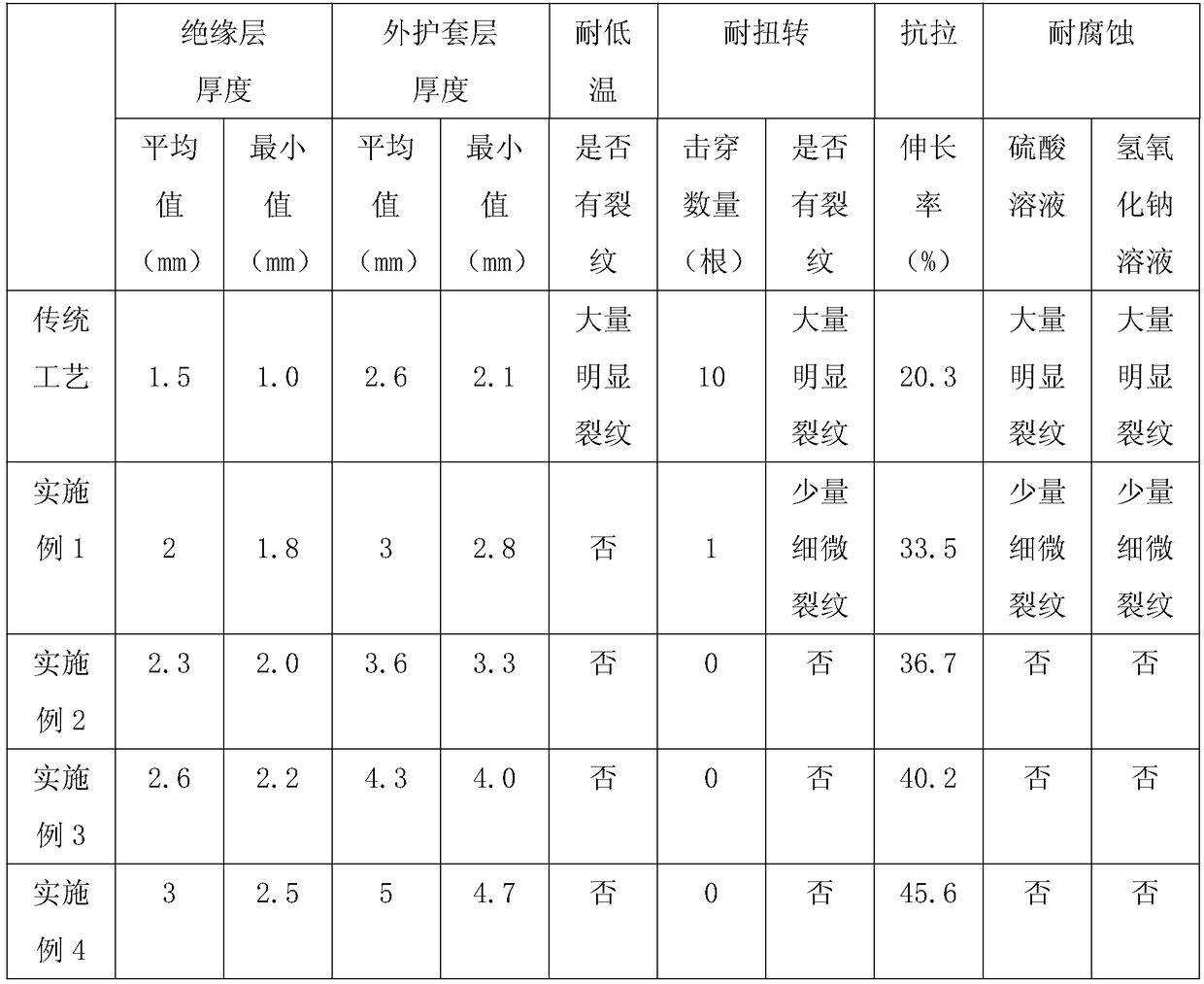

Embodiment 1

[0058] Embodiment 1 discloses a method for preparing a low-temperature-resistant torsion-resistant cable for wind power generation, including the following preparation steps:

[0059] Step a: wire drawing annealing

[0060] Use a wire drawing machine to stretch the copper rod to obtain copper wire. The speed of the wire drawing machine is 1450-1560r / min, and the diameter of the copper wire is 1-2mm. Then, anneal the copper wire:

[0061] The specific steps of annealing treatment include:

[0062] Put the copper wire into the heating furnace and seal the heating furnace, then raise the temperature in the heating furnace to 500-600°C and keep it warm for 4-5 hours, then take the copper wire out of the heating furnace and put it into a vacuum environment to cool naturally to At room temperature, put the copper wire into the copper antioxidant and soak it for 5-10 minutes, then take it out for drying treatment, and obtain the conductor;

[0063] Step b: Preparation of guide core...

Embodiment 2

[0089] Embodiment 2 discloses a method for preparing a low-temperature-resistant torsion-resistant cable for wind power generation, including the following preparation steps:

[0090] Step a: wire drawing annealing

[0091] Use a wire drawing machine to stretch the copper rod to obtain copper wire. The speed of the wire drawing machine is 1450-1560r / min, and the diameter of the copper wire is 1-2mm. Then, anneal the copper wire:

[0092] The specific steps of annealing treatment include:

[0093] Put the copper wire into the heating furnace and seal the heating furnace, then raise the temperature in the heating furnace to 500-600°C and keep it warm for 4-5 hours, then take the copper wire out of the heating furnace and put it into a vacuum environment to cool naturally to At room temperature, put the copper wire into the copper antioxidant and soak it for 5-10 minutes, then take it out for drying treatment, and obtain the conductor;

[0094] Step b: Preparation of guide core...

Embodiment 3

[0120] Embodiment 3 discloses a method for preparing a low-temperature-resistant torsion-resistant cable for wind power generation, including the following preparation steps:

[0121] Step a: wire drawing annealing

[0122] Use a wire drawing machine to stretch the copper rod to obtain copper wire. The speed of the wire drawing machine is 1450-1560r / min, and the diameter of the copper wire is 1-2mm. Then, anneal the copper wire:

[0123] The specific steps of annealing treatment include:

[0124] Put the copper wire into the heating furnace and seal the heating furnace, then raise the temperature in the heating furnace to 500-600°C and keep it warm for 4-5 hours, then take the copper wire out of the heating furnace and put it into a vacuum environment to cool naturally to At room temperature, put the copper wire into the copper antioxidant and soak it for 5-10 minutes, then take it out for drying treatment, and obtain the conductor;

[0125] Step b: Preparation of guide core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com