Underwater welding robot mobile carrier

An underwater welding and mobile carrier technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor underwater image effect, incomprehensible understanding of ground personnel, missing welding, etc., and achieve strong Usability, Imaging Improvement and Comprehensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

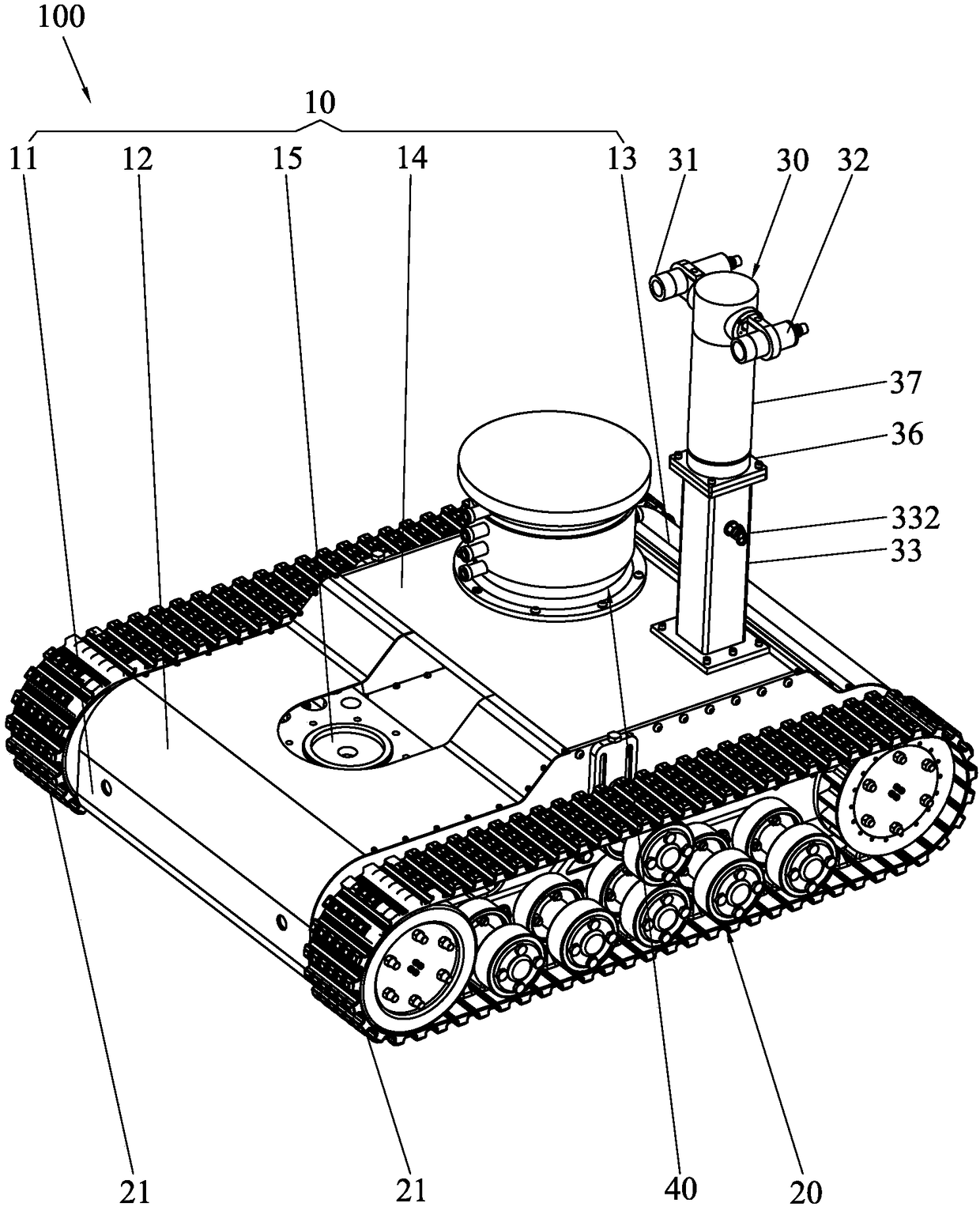

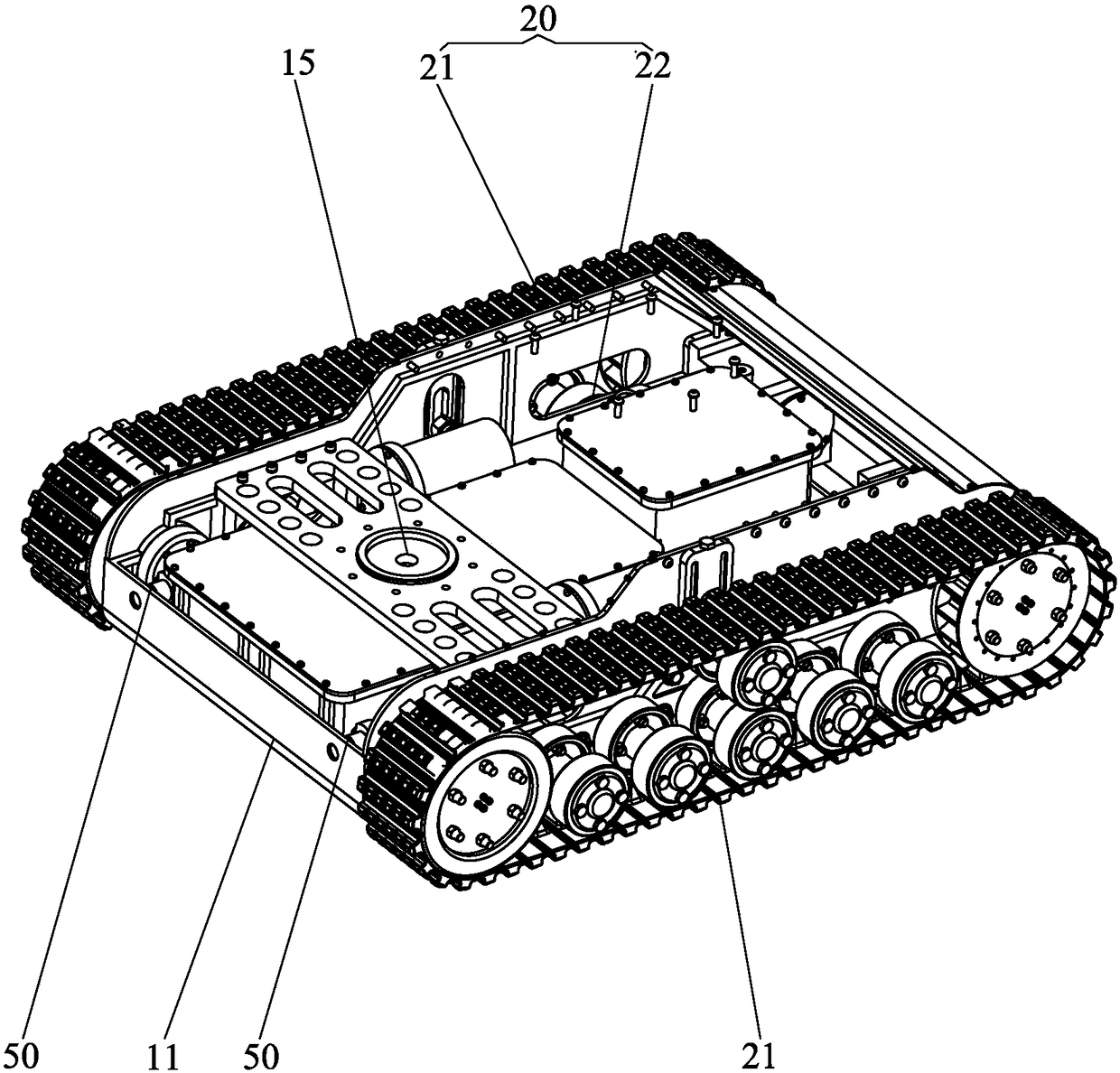

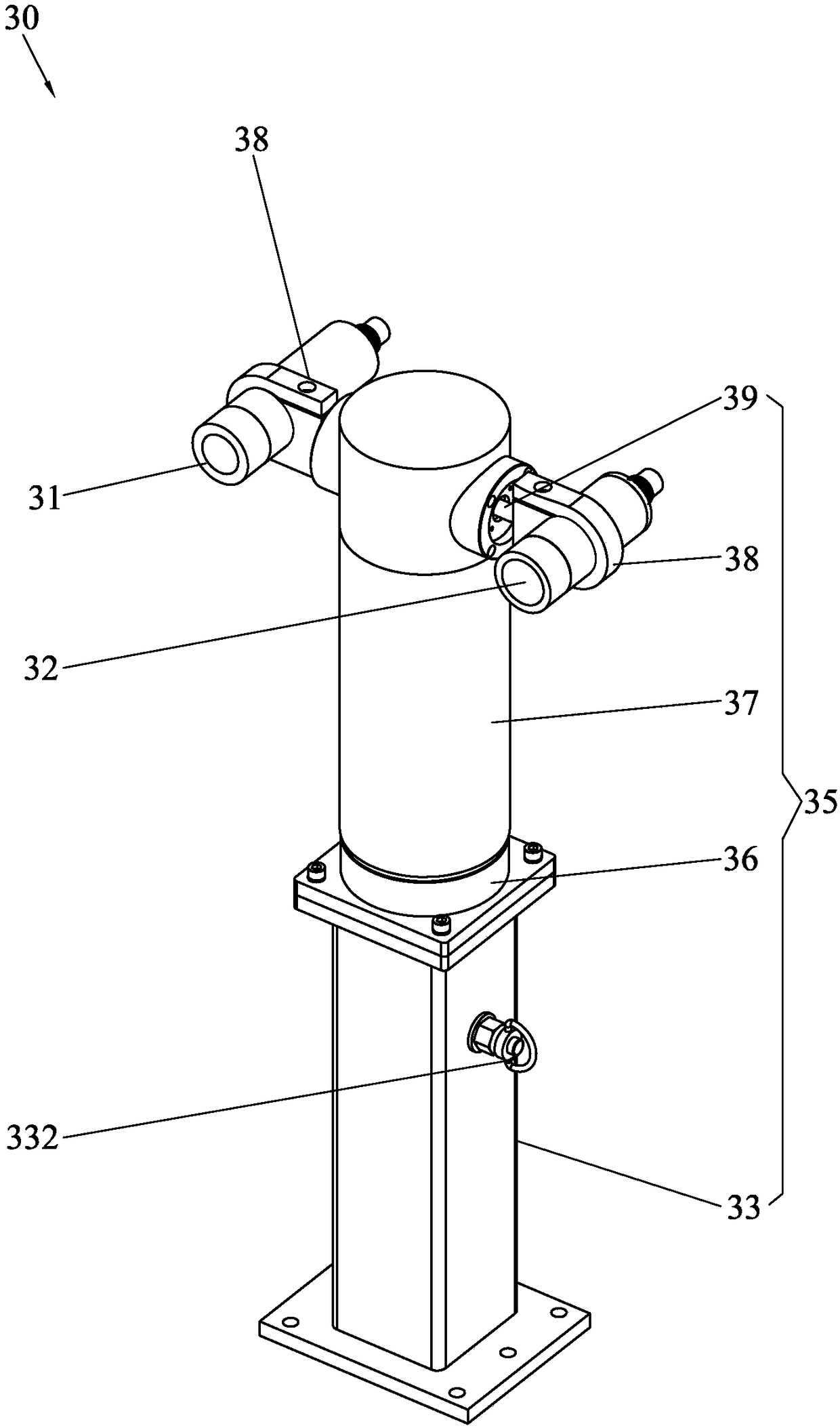

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0020] Such as Figure 1-Figure 4 As shown, the mobile carrier 100 of the underwater welding robot of the present invention is used to carry the welding equipment to walk in the pool and perform welding. It is mainly used in underwater environments such as spent fuel pools and storage pools. This embodiment only uses The spent fuel pool is used as an example for illustration. The working principle and effect of pools such as pile pools are exactly the same, and will not be described in detail here; the underwater welding robot mobile carrier 100 includes a vehicle body module 10, a walking module 20 and a camera module 30. The walking module 20 is arranged on the vehicle body module 10, and the walking module 20 drives the vehicle body module 10 to walk. Walking in the fuel pool, during the walking process, the camera 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com