Bow thruster coupler shrinkage fit tool

A coupling and red sleeve technology is applied in the field of bow thrust coupling red sleeve tooling, which can solve the problem of inability to operate with bare hands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

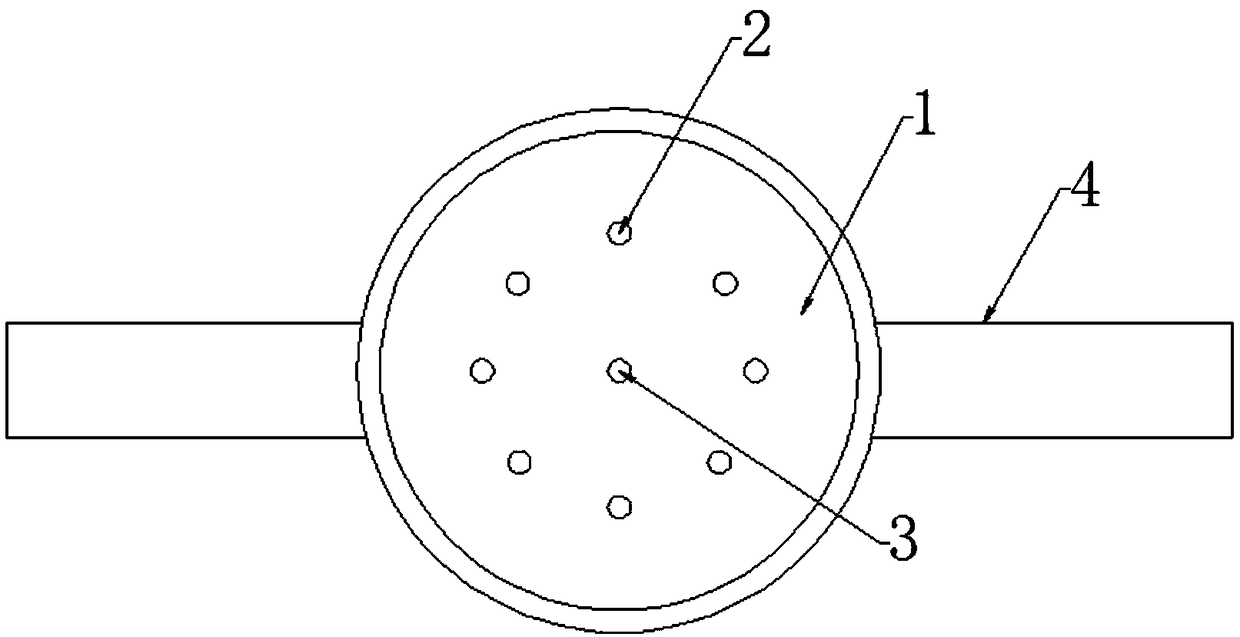

[0020] like figure 1 As shown, the present invention is a bow thruster coupling red sleeve tooling, including a tray 1, a number of hollow cylinders 2 are evenly arranged in the center of the tray bottom plate, and the height of the cylinders is not greater than the height of the coupling. The radius of the circle surrounded by the cylinder is greater than the radius of the coupling, and a heating component is arranged in the cylinder; a through hole 3 is arranged at the center of the tray, a cylindrical protrusion is arranged on the through hole, and an internal thread is arranged on the inner wall of the cylindrical protrusion; A handle 4 is provided on the outer periphery of the tray.

[0021] The method of fitting the coupling vertically to the motor shaft is as follows: firstly heat and expand the coupling to the required size at the heating source, then place the heated and expanded coupling on the tooling pallet by hoisting or clamping In the circular accommodation cav...

Embodiment 2

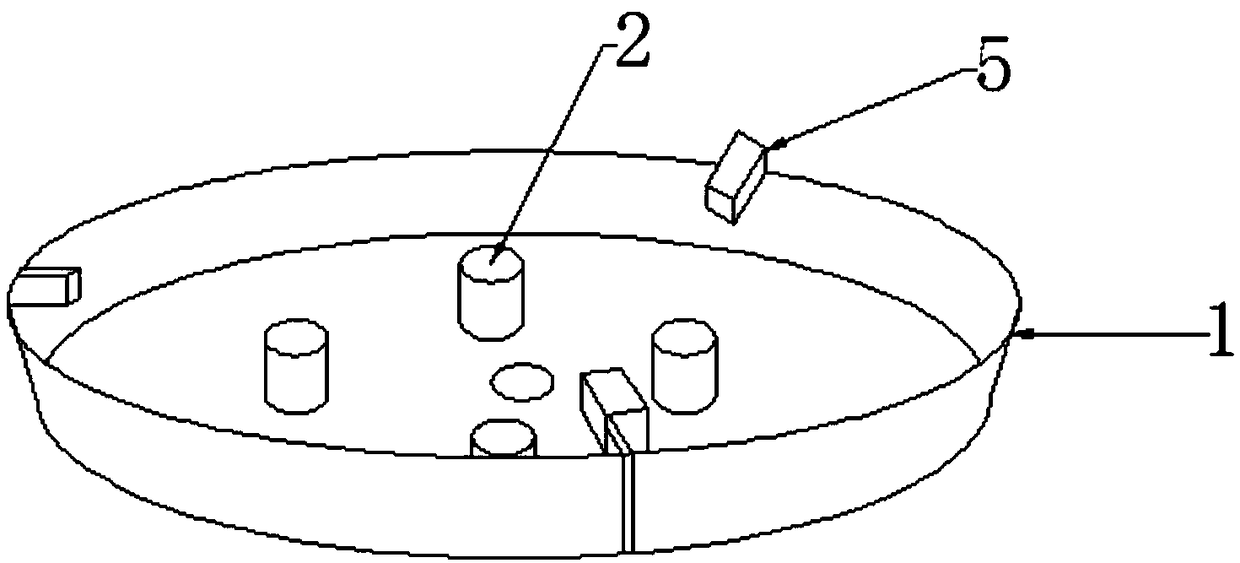

[0023] like figure 2 As shown, a bow thruster coupling red sleeve tooling includes a tray 1, and a number of hollow cylinders 2 are uniformly arranged in the center of the tray bottom plate. The height of the cylinders is not greater than the height of the coupling. The radius of the enclosed circle is greater than the radius of the coupling, and a heating component is provided in the cylinder; a cold air system is provided on the lower surface of the tray, and several air outlets 5 of the cold air system are evenly arranged on the outer edge of the tray, and all face the center of the tray .

Embodiment 3

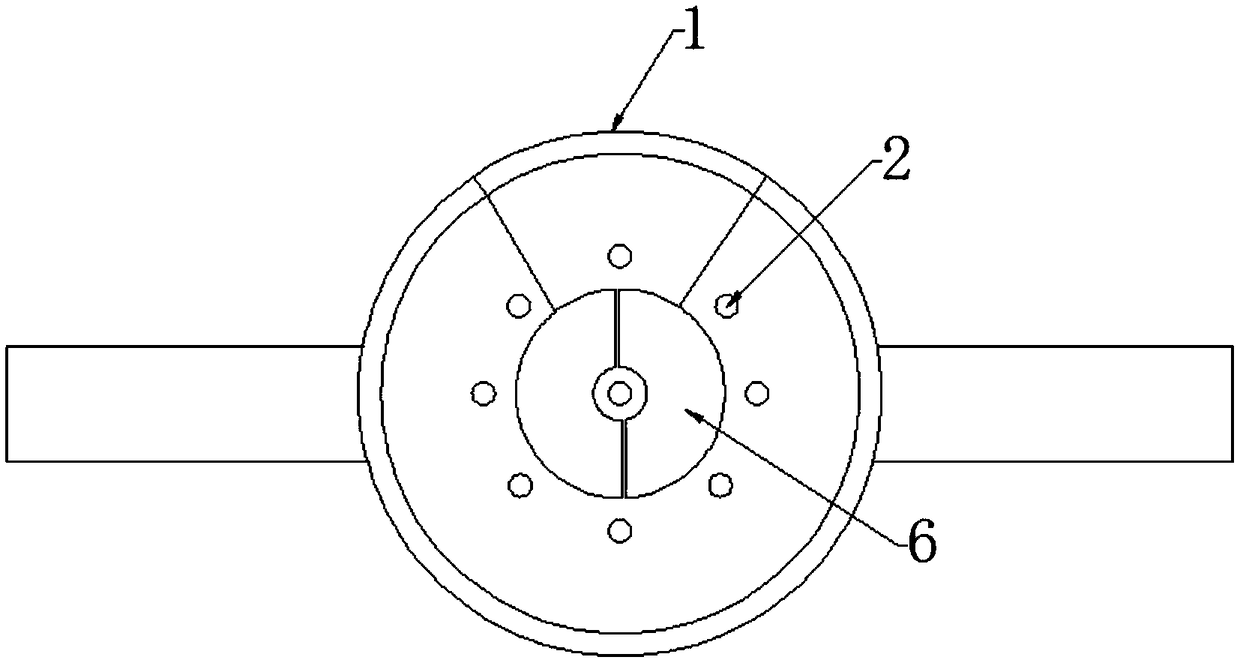

[0025] like image 3 , 4 As shown, a bow thruster coupling red sleeve tooling includes a tray 1, and a number of hollow cylinders 2 are uniformly arranged in the center of the tray bottom plate. The height of the cylinders is not greater than the height of the coupling. The radius of the enclosed circle is larger than the radius of the coupling, and a heating component is arranged in the cylinder; the circular bottom plate area surrounded by the cylindrical protrusion on the bottom plate of the tray and several hollow cylinders is provided with an arc-shaped sheet temperature sensor 6. The temperature sensor is sequentially connected with the digital display screen 7 and the power supply 8 on the bottom surface of the pallet; a level 9 is arranged on the bottom surface of the pallet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com