A positive pressure air lock with anti-blocking function

A kind of air-closing device and function technology, applied in the field of air-closing device, can solve the problems such as damage to the air-closing device blade, delaying production time, affecting normal production, etc., to avoid downtime for repair, improve efficiency, and automate the anti-blocking function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

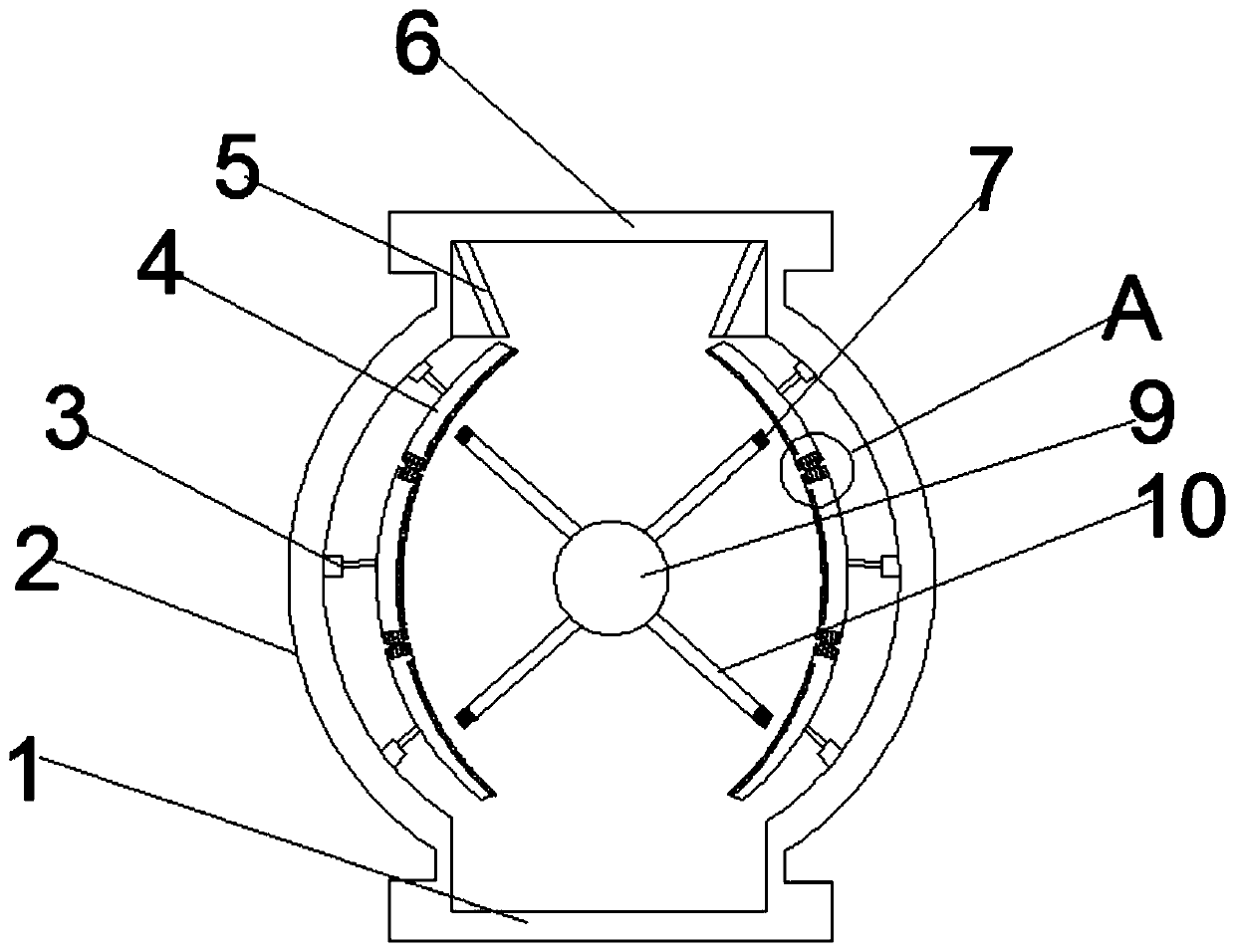

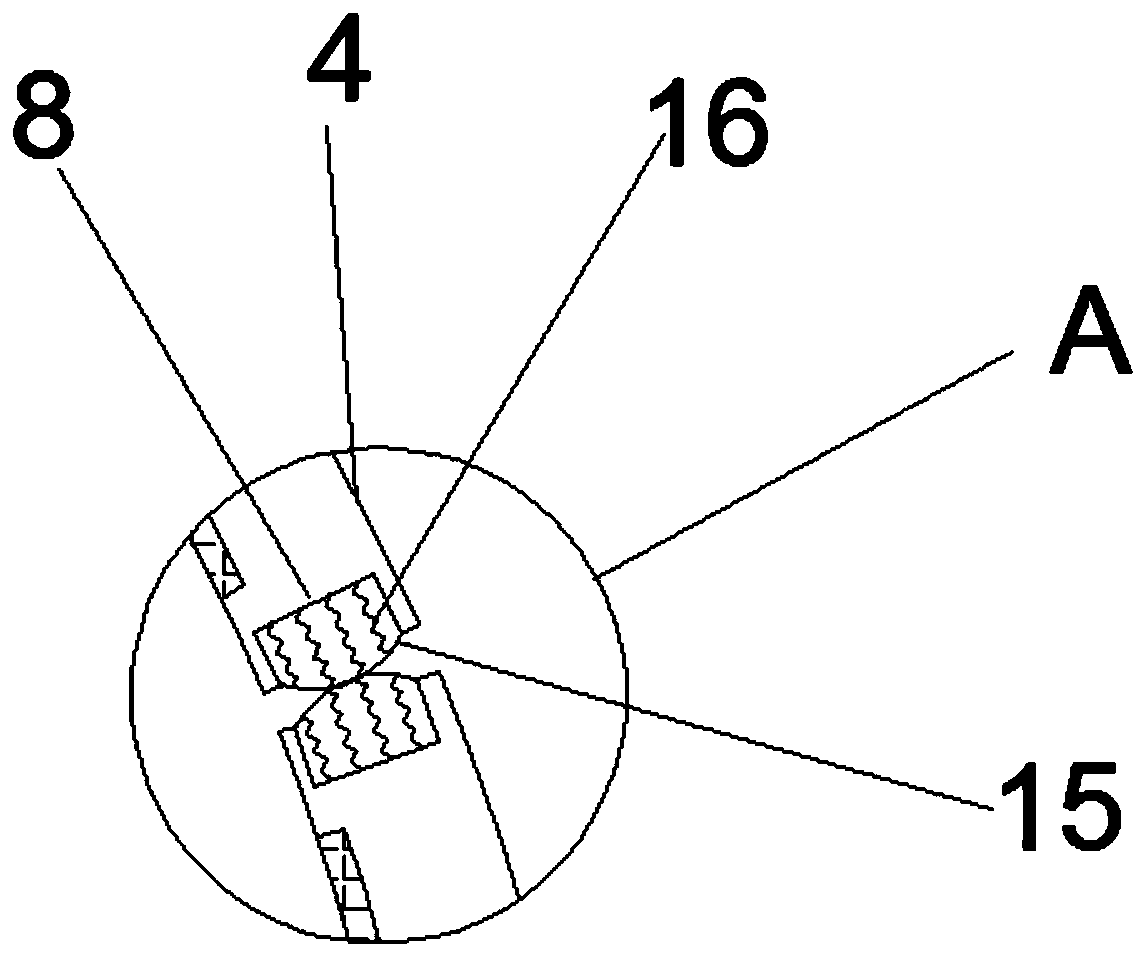

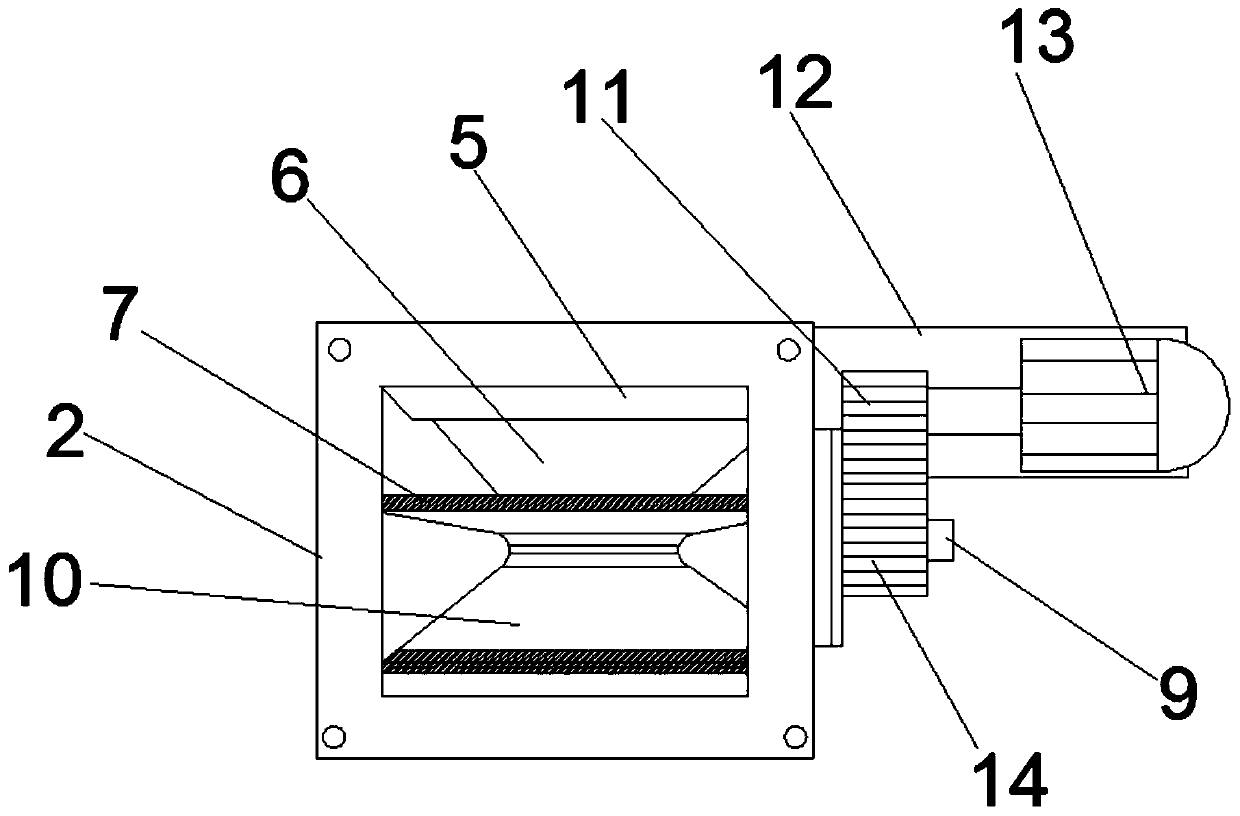

[0031] refer to Figure 1-3 , the present invention provides a positive pressure air lock with anti-blocking function, including the air lock housing 2, the feed port 6 and the discharge port 1 connected to the air lock housing 2, and the air lock housing The rotating shaft 9 inside the housing 2, the blades 10 connected to the rotating shaft 9, and the driving mechanism 13 that drives the rotating shaft 9 to rotate. There are multiple arc-shaped activities connected between the inside of the housing 2 and the blades 10 through the telescopic mechanism 3. The plate 4 and a plurality of arc-shaped movable plates 4 cooperate with each other to form the inner cavity of the air lock, and the arc-shaped movable plate 4 is connected with a pressure sensor electrically connected with the telescopic mechanism 3 .

[0032] Working principle: When using the positive pressure air lock with anti-blocking function in this application, the material is put into the trough formed by the blade...

Embodiment 2

[0035] refer to Figure 1-3 , based on Embodiment 1, in this embodiment, one end of the vane 10 close to the interior of the air lock housing 2 is connected with an elastic rubber 7 , and the elastic rubber is bonded to the vane 10 by an adhesive.

[0036] By connecting the elastic rubber 7 at one end of the blade 10, when materials are clamped between the elastic rubber 7 and the arc-shaped movable plate 4 to form pressure, the generated pressure first presses the elastic rubber 7, and the elastic rubber 7 plays a role. The function of cushioning, the elastic function of the elastic rubber 7 can also increase the distance between the arc-shaped movable plate 4 and the elastic rubber 7 when compressed, further preventing the blockage caused by the material, and has a certain effect on the blade 10 of the air lock. The protection function reduces the possibility of damage to the blade 10 and further reduces the maintenance cost of the blade 10 . Wherein the shortest distance b...

Embodiment 3

[0038] refer to Figure 1-3 , based on Embodiment 1, a plurality of arc-shaped movable plates 4 in this embodiment are provided with sealing assemblies between adjacent ones.

[0039] Since the arc-shaped movable plate 4 is spliced inside the air locker shell by multiple splicing, there may be a certain gap between the arc-shaped movable plates 4, if the material enters between the movable plate and the air locker shell through the gap, If the long-term accumulation is too much, the telescopic mechanism 3 will also have difficulties in the process of driving the arc-shaped movable plate 4 to move. Therefore, this application further provides a sealing assembly between adjacent contacting movable plates, which can be avoided by installing the sealing assembly. The material enters between the arc-shaped movable plate 4 and the housing of the air lock, causing difficulty in preventing blockage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com