A kind of titanium-cobalt alloy and preparation method thereof

A titanium-cobalt alloy and cobalt powder technology, applied in the field of alloys, can solve the problems of uneven alloy composition, alloy liquid pollution, violation of environmental protection, etc., and achieve the effects of low impurity content, environmental protection, and enhanced corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

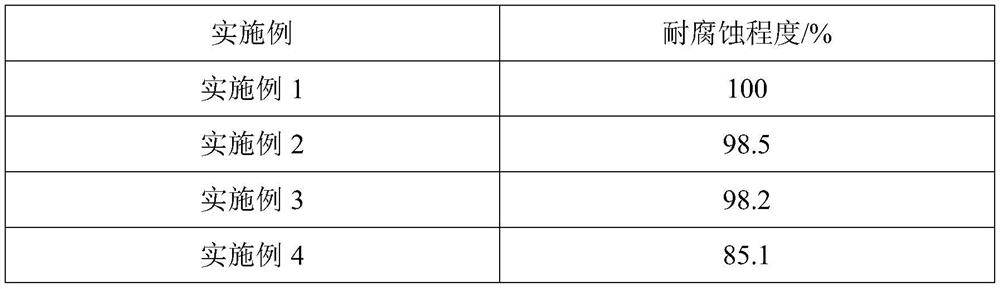

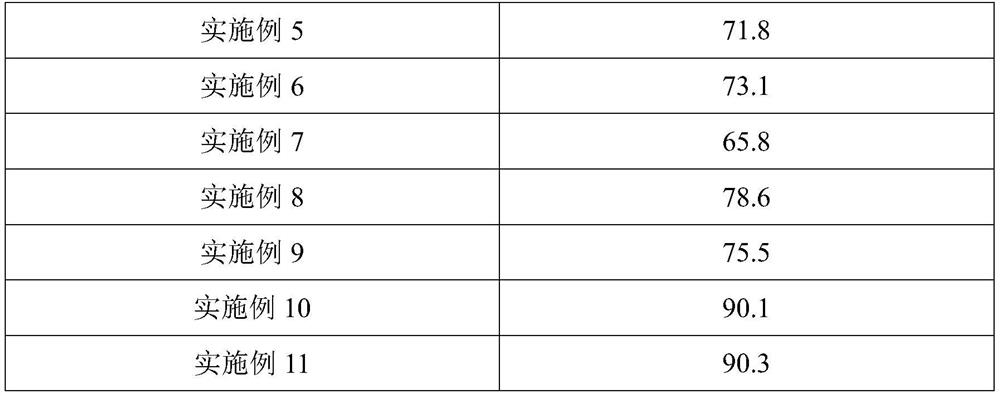

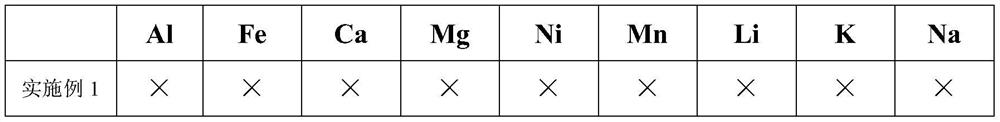

Examples

preparation example Construction

[0041] In order to solve the above problems, a second aspect of the present invention provides a method for preparing a titanium-cobalt alloy, comprising the following steps:

[0042] S1: Mix the formula quantity of tungsten carbide, titanium carbide, copper-zinc composite powder and chromium carbide evenly, and grind to obtain component A; mix the formula quantity of cobalt powder and rare earth metal powder evenly, and grind to obtain component B ;

[0043] S2: Add component A into the crucible for primary smelting. After it is completely melted, add component B to it for secondary smelting. After it is completely melted, air-cool to obtain intermediate alloy C;

[0044] S3: heat up the intermediate alloy C, melt it and magnetically stir it until uniform, let it stand still, cast an ingot, take it out of the furnace and air-cool; heat up again, and air-cool it to room temperature to prepare a titanium-cobalt alloy.

[0045] Wherein, the crucible is a quartz crucible. Quart...

Embodiment 1

[0058] The first aspect of embodiment 1 provides a kind of titanium-cobalt alloy, and preparation raw material comprises following composition:

[0059] 75 parts of tungsten carbide, 13 parts of titanium carbide, 27 parts of cobalt powder, 1.5 parts of chromium carbide, 2 parts of rare earth metal powder, 5 parts of copper-zinc composite powder. The ratio of the copper-zinc alloy powder is 1:2. The rare-earth metal powder is a combination of rare-earth metals Dy and Ga at a ratio of 2:1 by weight.

[0060] The second aspect of embodiment 1 provides a method for preparing a titanium-cobalt alloy, comprising the following steps:

[0061] S1: Mix the formula quantity of tungsten carbide, titanium carbide, copper-zinc composite powder and chromium carbide evenly, and grind to obtain component A; mix the formula quantity of cobalt powder and rare earth metal powder evenly, and grind to obtain component B ;

[0062] S2: Add component A into the crucible, vacuumize the furnace bod...

Embodiment 2

[0065] The first aspect of embodiment 2 provides a kind of titanium-cobalt alloy, and preparation raw material comprises following composition:

[0066] 60 parts of tungsten carbide, 11 parts of titanium carbide, 25 parts of cobalt powder, 1 part of chromium carbide, 1 part of rare earth metal powder, 2 parts of copper-zinc composite powder. The ratio of the copper-zinc alloy powder is 1:2. The rare-earth metal powder is a combination of rare-earth metals Dy and Ga at a ratio of 2:1 by weight.

[0067] The second aspect of Example 2 provides a method for preparing a titanium-cobalt alloy, and the preparation steps are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com