Manufacturing method of large air preheater

A technology of an air preheater and a manufacturing method, applied in the field of boilers, can solve the problems of inconvenience and heavy transportation of large air preheaters, and achieve the effects of improving stability, reducing overall quality and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

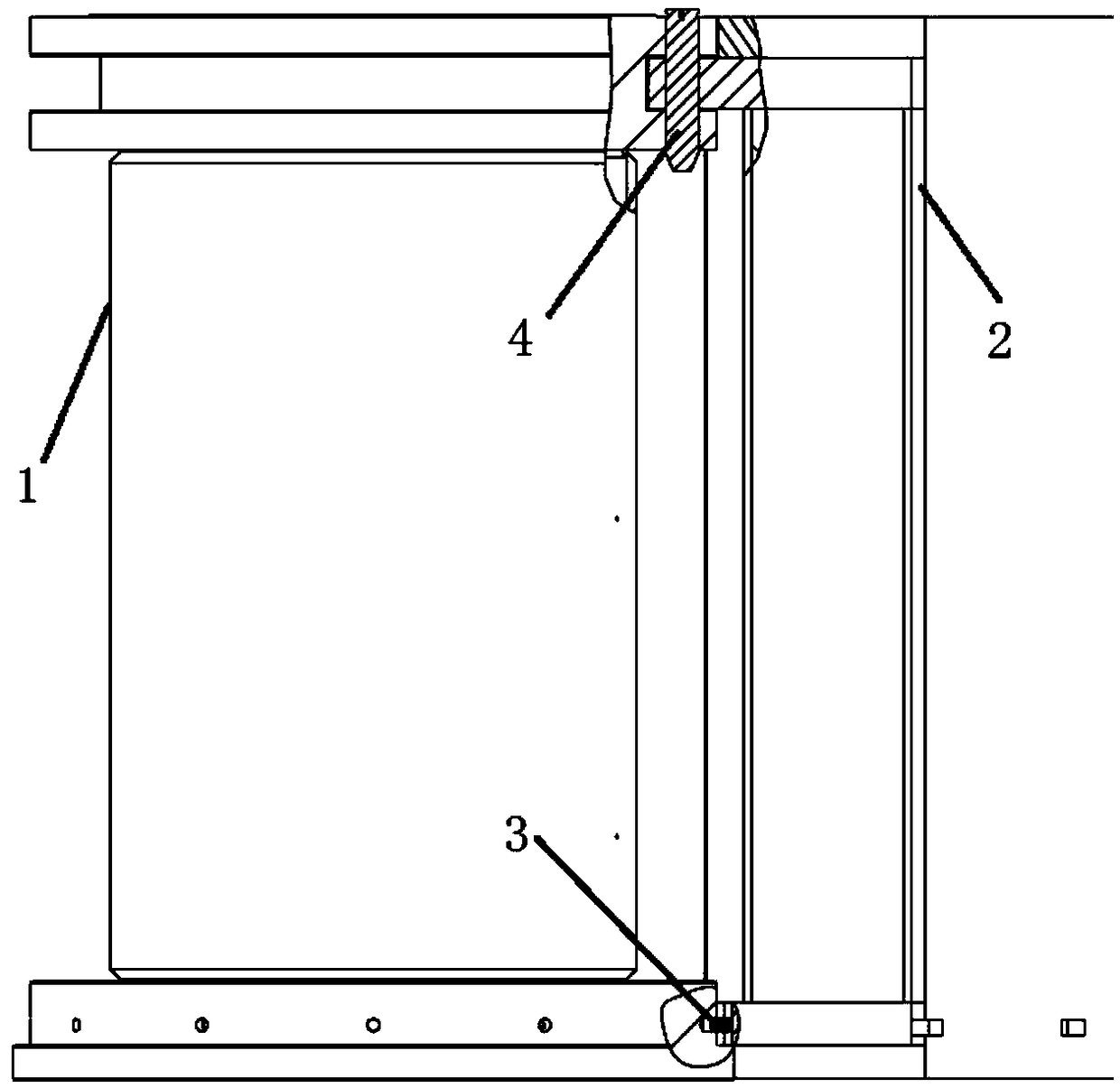

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] like Figure 6 ~ Figure 11 Shown, the manufacture method of large-scale air preheater of the present invention comprises the following steps:

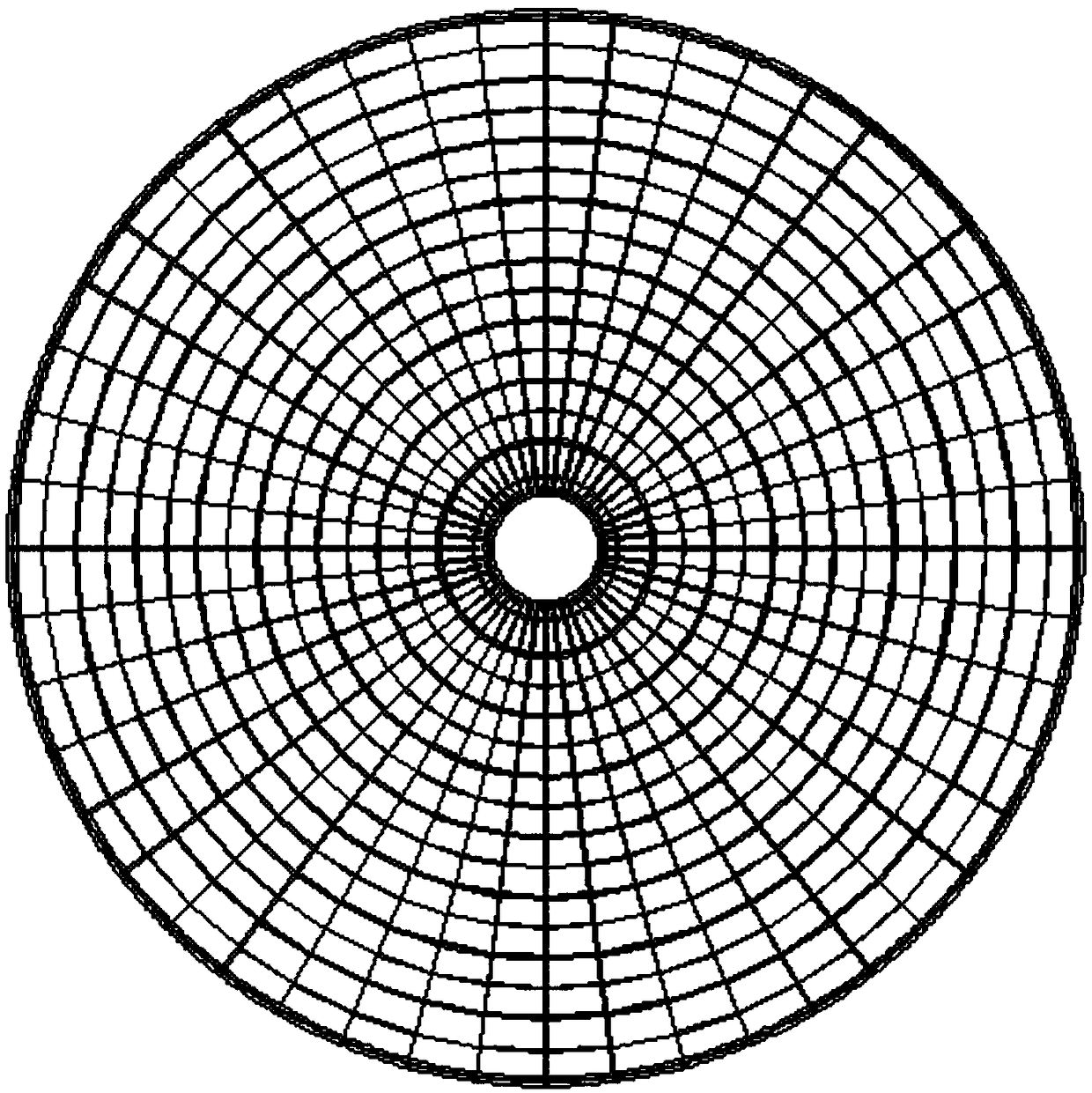

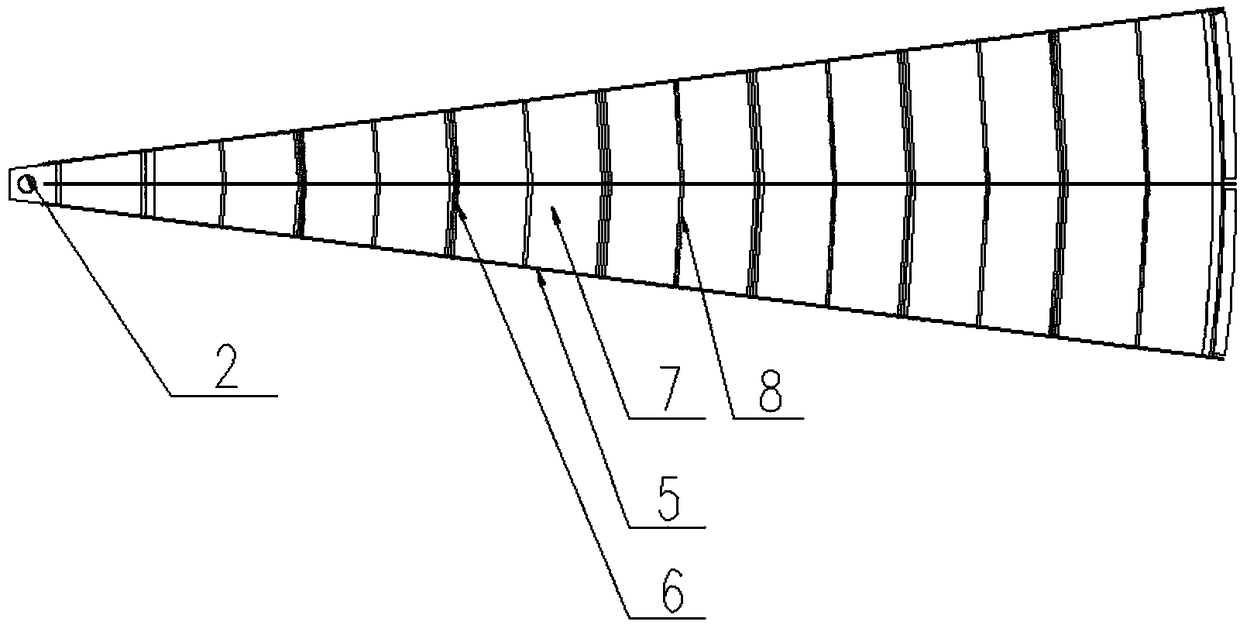

[0037] (1) Prefabrication of the inner and outer ring compartments at the production site: divide the compartment part of the air preheater into multiple fan-shaped inner rings distributed around the circumference of the central cylinder according to the designed radial size and circumferential division The bins 9 and a plurality of fan-ring outer ring bins 12, the outer ring bins 12 are connected to the central cylinder 1 through the inner ring bins 9, the inner ring bins 9 are formed by the inner ring radial partition 10 and the inner ring ring Composed of partitions 11, the outer ring compartment 12 is composed of radial partitions 13 of the outer ring and circumferential partitions 14 of the outer ring;

[0038] (2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap