Automatic overheating prompt device of high-voltage lead joint

A technology of high-voltage wires and automatic prompting, which is applied to measuring devices, measuring heat, and parts of thermometers, etc., can solve problems such as inability to actively alarm, dangerous accidents, and current leakage, and achieve easy large-scale manufacturing and installation, and simple operation and control , The effect of real-time temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

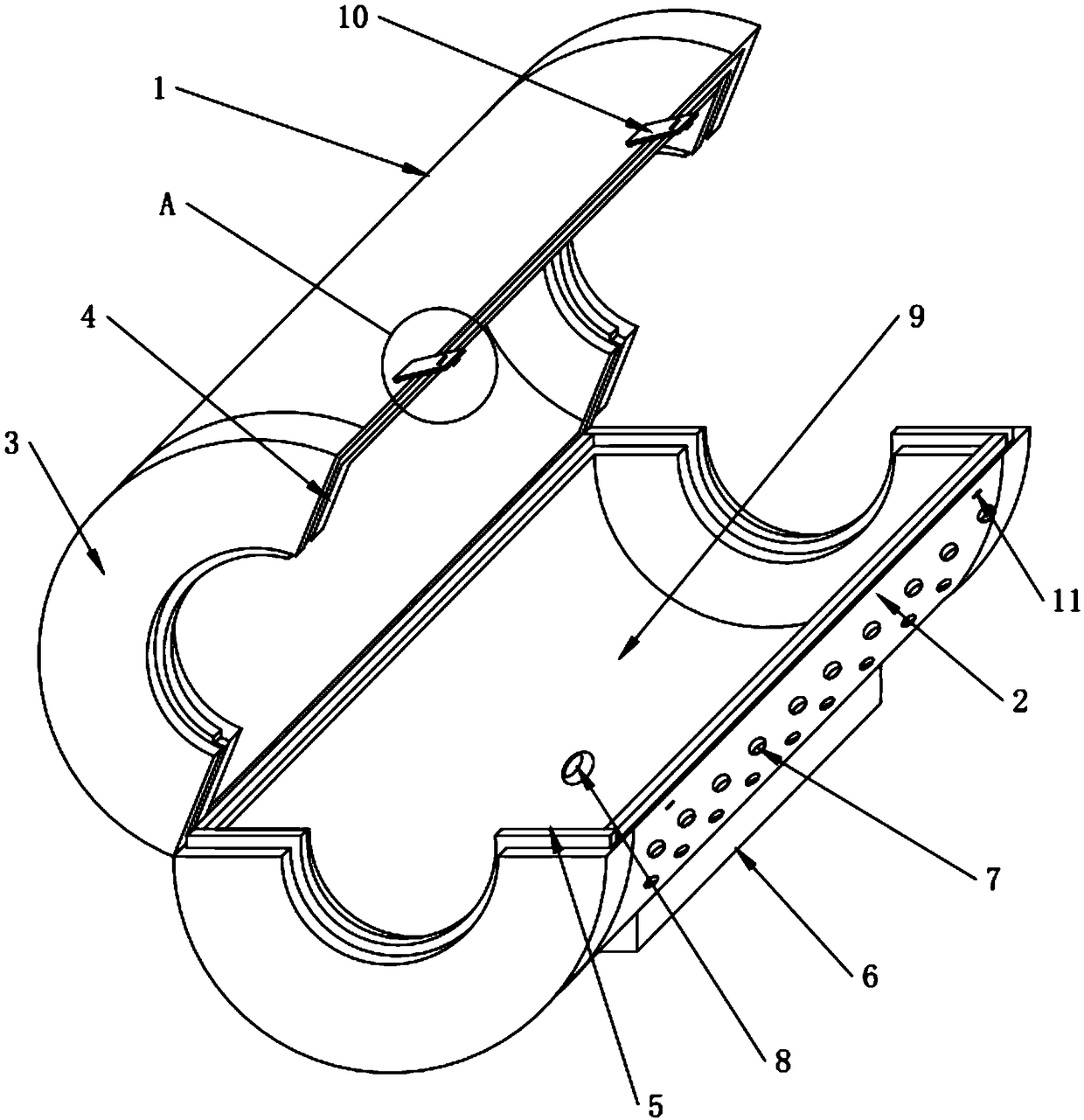

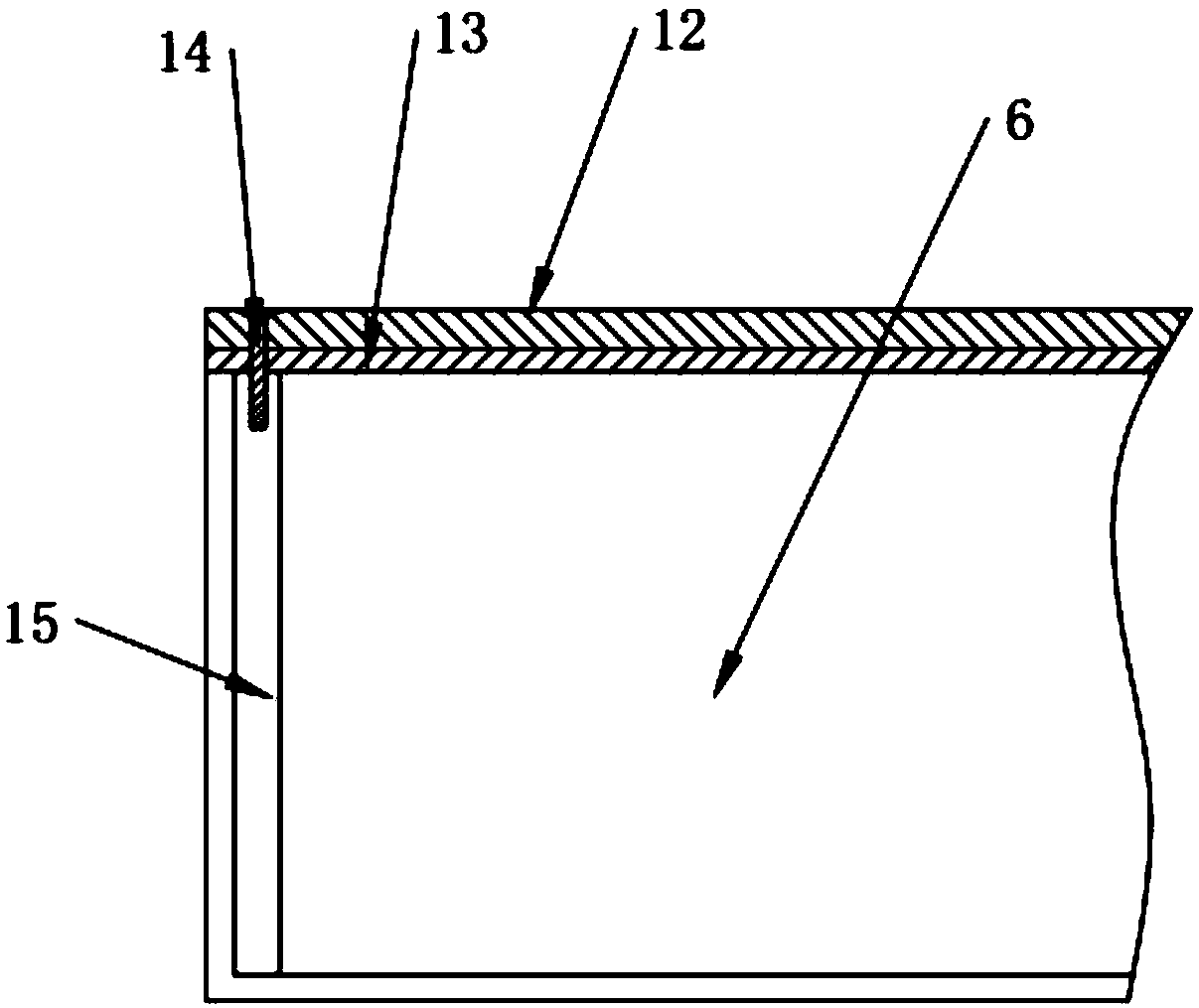

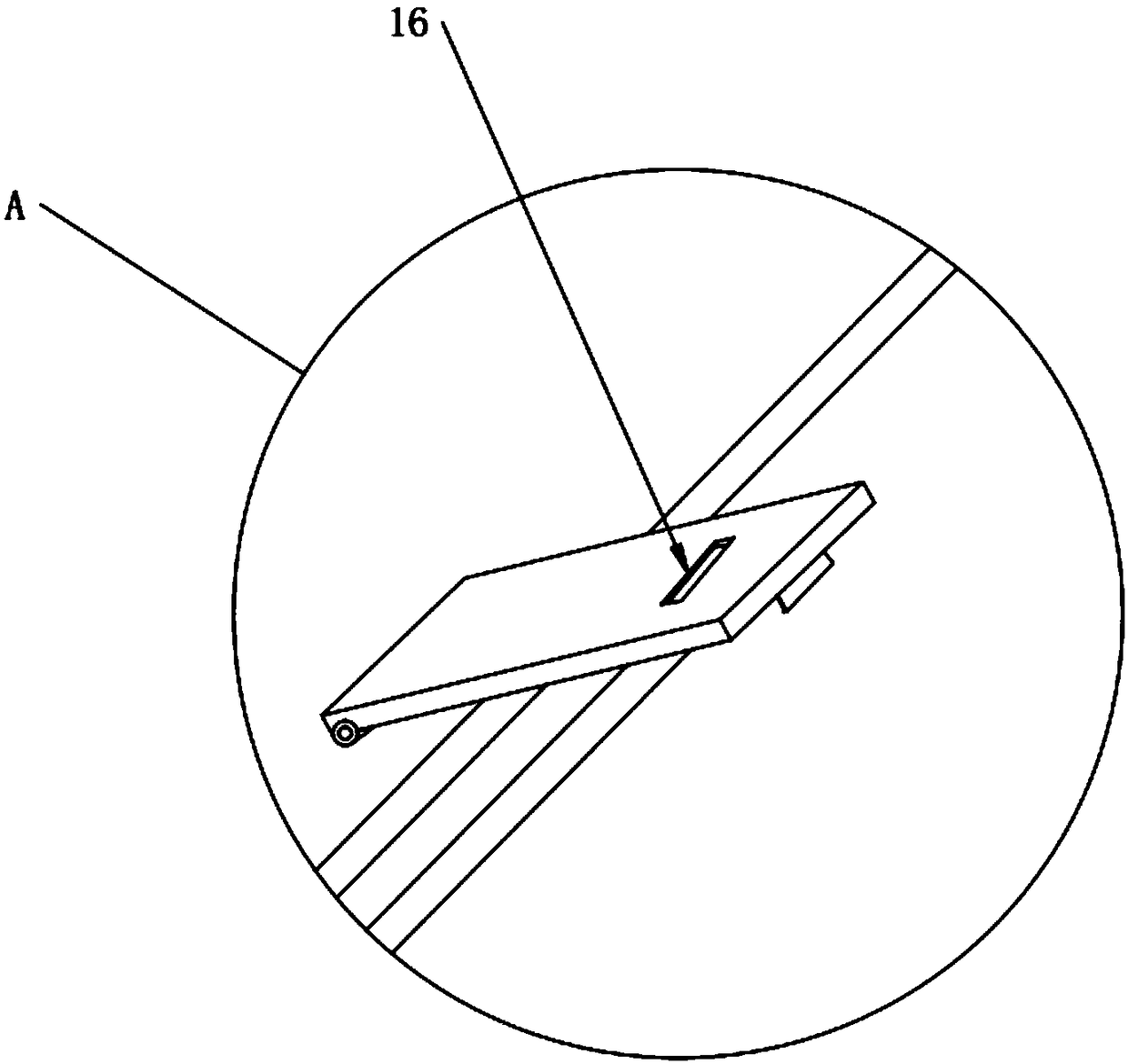

[0030] Such as figure 1 As shown, the overheating automatic warning device for high-voltage wire joints includes an upper shell 1 and a lower shell 2 that are butted up and down, and a sealed space 9 is formed by the area covered between the upper shell 1 and the lower shell 2, And one common end of the upper shell 1 and the lower shell 2 is hinged, and the other end opposite to the hinged end is an opening and closing end, and the high-voltage wire joint is covered in the sealed space 9 through the opening and closing end; An installation shell 6 is arranged on the outer bottom surface of the housing 6, and a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com