Small oilseed rape seeding machine

A seeder and rapeseed technology, which is applied in the direction of fertilizer and seeding equipment, can solve the problems of no spacing between plants and rows, interplanting, uneven emergence rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

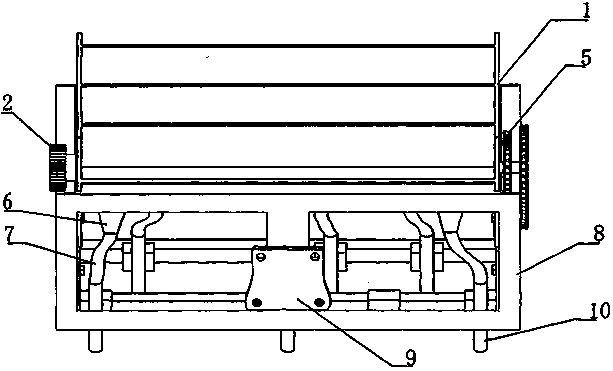

[0009] The embodiment of the present invention: the seed fertilizer box (1) is provided with a sowing amount adjustment knob (2) and a fertilizer amount adjustment knob on the lower left side, and a driven sprocket shaft (3) and a driven sprocket disk (4) are provided on the lower right side. , Seed box sprocket shaft, fertilizer box sprocket shaft, seed box sprocket, fertilizer box sprocket, seed fertilizer drive chain (5) are installed at the two sprockets of seed fertilizer, and the bottom of the seed box (1) is equipped with a seeder, Seed box (6), seed guide tube (7); the front of the frame (8) is provided with a connecting plate (9), the bottom of the frame is provided with three openers (10) at the front and rear, and at the bottom of the frame (8) Drive the compaction roller (11) and install a roller shaft in the middle of the drum. The left side of the drum is equipped with a bearing and a bearing seat, and the right side of the drum is equipped with a bearing, bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com