Flue-cured tobacco management and flue-curing method based on salicylic acid application to alleviate gray tobacco

The technology of a management method and a curing method, applied in the field of tobacco cultivation, can solve the problems of time-consuming and labor-intensive, insignificant relief effect, etc., and achieve the effects of being easy to operate, inhibiting the further spread of the disease, and being convenient to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

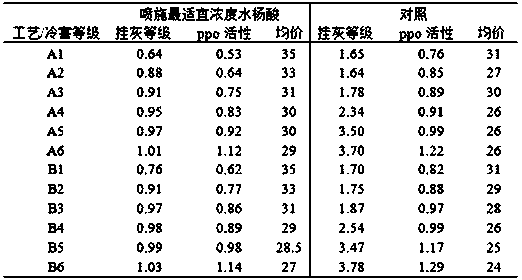

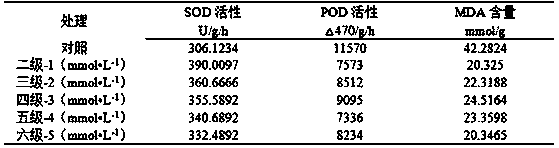

[0079] A flue-cured tobacco management method based on salicylic acid application to alleviate gray smoke, comprising the following steps:

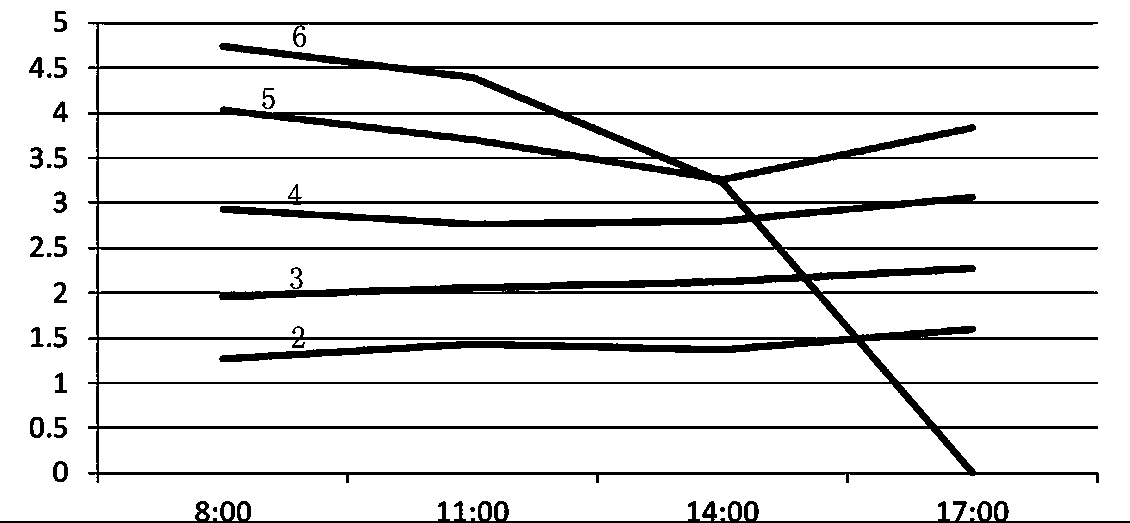

[0080] 1) Tobacco leaf gray grade identification and one-time spraying: Grade identification is carried out on the tobacco plants with gray smoke, and the disease degree of gray flue-cured tobacco is divided into six levels as follows:

[0081] Grade 0: The whole leaf is disease-free;

[0082] Grade 1: sporadically distributed gray-black spots on the main vein or branch veins, not exceeding 5% of the leaf area;

[0083] Grade 2: Gray black spots occupy 5%-15% of the leaf area:

[0084] Grade 3: Gray black spots occupy 15%-30% of the leaf area;

[0085] Grade 4: Gray black spots account for 30%-45% of the leaf area;

[0086] Grade 5: Gray black spots account for more than 45% of the leaf area;

[0087] Grade 6: gray-black spots occupy more than 45% of the leaf area, and gray-black spots appear on the petiole and spread to the stem;

...

Embodiment 2

[0100] A flue-cured tobacco management method based on the application of salicylic acid to alleviate gray smoke, comprising the following steps:

[0101] 1) Tobacco leaf gray grade identification and one-time spraying: The tobacco plants with gray smoke are graded and the disease degree of gray flue-cured tobacco is divided into six grades as follows:

[0102] Grade 0: The whole leaf is disease-free;

[0103] Grade 1: The main veins or branches are scattered with gray-black spots, not exceeding 5% of the leaf area;

[0104] Grade 2: Grey-black spots occupy 5%-15% of leaf area:

[0105] Level 3: gray-black spots occupy 15%-30% of the leaf area;

[0106] Grade 4: gray-black spots occupy 30%-45% of the leaf area;

[0107] Grade 5: gray-black spots occupy more than 45% of the leaf area;

[0108] Grade 6: gray-black spots occupy more than 45% of the leaf area, and gray-black spots appear on petioles and spread to the stem;

[0109] When grading tobacco plants that produce gra...

Embodiment 3

[0121] A flue-cured tobacco management method based on the application of salicylic acid to alleviate gray smoke, comprising the following steps:

[0122] 1) Tobacco leaf gray grade identification and one-time spraying: The tobacco plants with gray smoke are graded and the disease degree of gray flue-cured tobacco is divided into six grades as follows:

[0123] Grade 0: The whole leaf is disease-free;

[0124] Grade 1: The main veins or branches are scattered with gray-black spots, not exceeding 5% of the leaf area;

[0125] Grade 2: Grey-black spots occupy 5%-15% of leaf area:

[0126] Level 3: gray-black spots occupy 15%-30% of the leaf area;

[0127] Grade 4: gray-black spots occupy 30%-45% of the leaf area;

[0128] Grade 5: gray-black spots occupy more than 45% of the leaf area;

[0129] Grade 6: gray-black spots occupy more than 45% of the leaf area, and gray-black spots appear on petioles and spread to the stem;

[0130] When grading tobacco plants that produce gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com