A device for weakening the oscillation energy of foam and pulp interface

A technology of oscillating energy and ore pulp, applied in the field of flotation machines, can solve the problems of not involving control, ignoring the interphase interaction of the interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

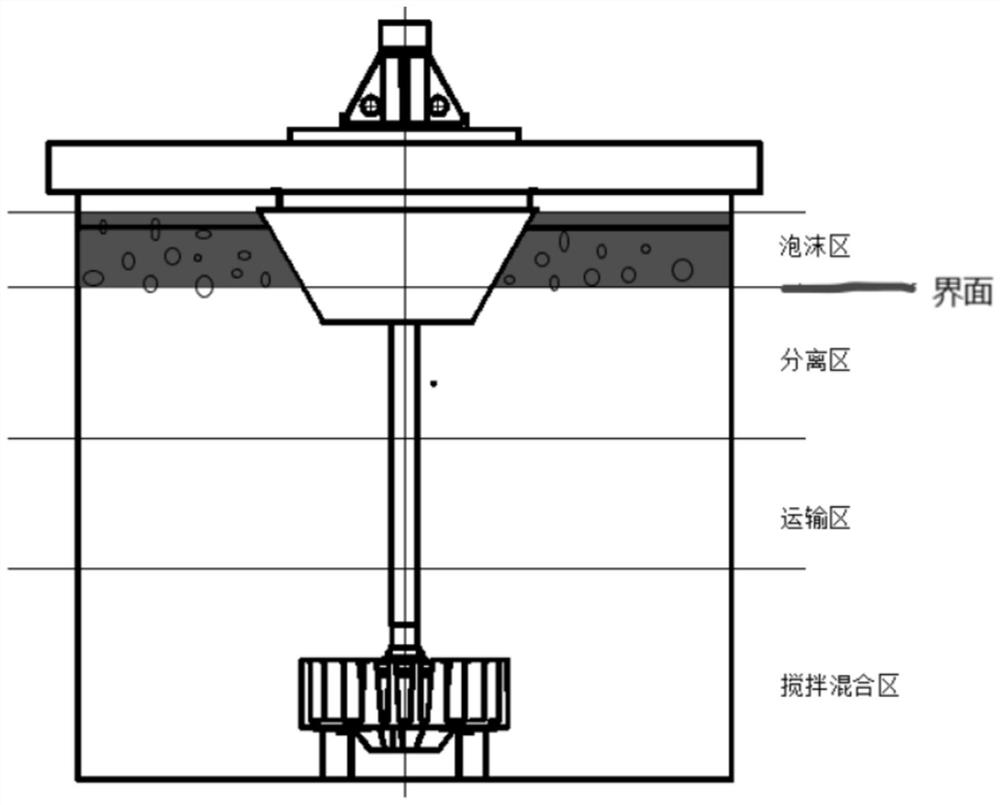

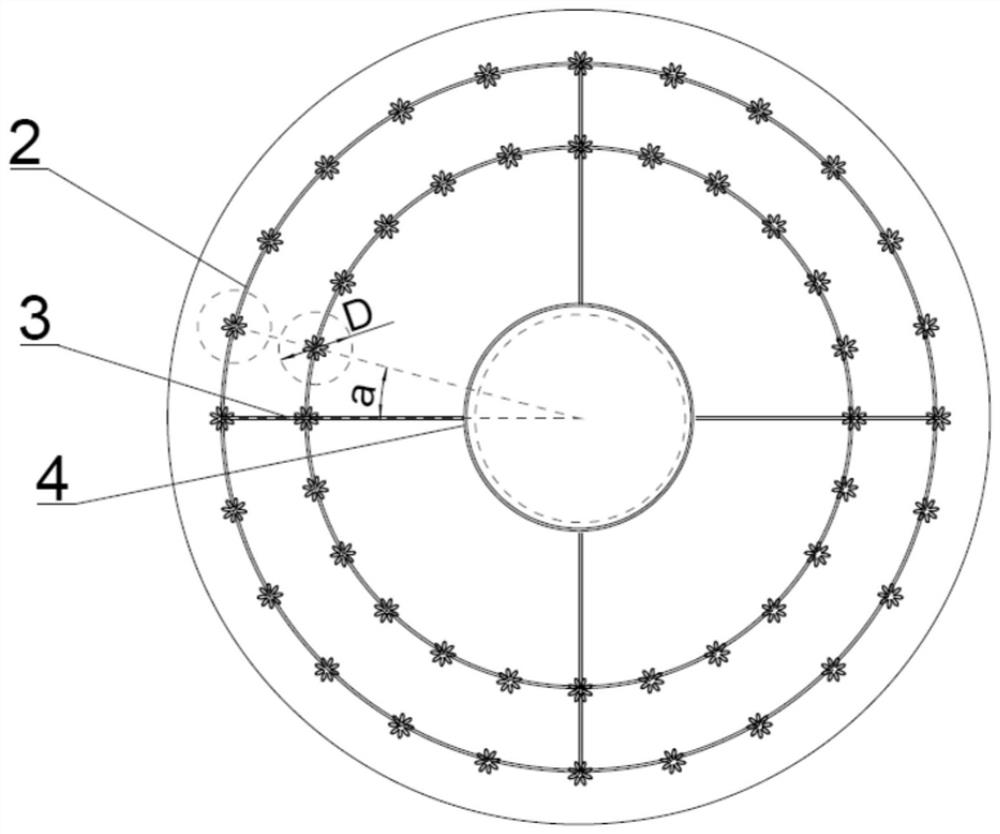

[0029] Such as Figure 2 to Figure 5 As shown, it consists of an oscillation damper 1, an annular air distribution pipe 2, a radial air distribution pipe 3 and a general air distribution pipe 4. The vibration damper 1 is placed on the interface and can naturally float in the slurry. Oscillation dampers 1 are evenly distributed along the circumferential direction, and the diameter D of each oscillator’s range of action is determined by the inflation rate of the flotation machine per unit area; the circumferentially distributed oscillation dampers 1 are connected with the annular air distribution pipe 2, and are composed of 4 diameter Lead to the air distribution pipe 3 to the general air distribution pipe 4 to all the vibration dampers 1 to distribute air to the latter to extract air. The annular air distribution pipe 2 and the radial air distribution pipe 3 are made of PVC material or other polymer materials with a certain hardness to ensure that all the vibration dampers 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com