Refractory brick double-station fast-switching forming equipment

A technology for fast switching and molding equipment, which is applied in the direction of ceramic molding machines, manufacturing tools, and supply devices. It can solve problems such as lack of integrated molding, potential safety hazards, and poor flattening effects, and achieve simple and ingenious structure, improved efficiency, and Add the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

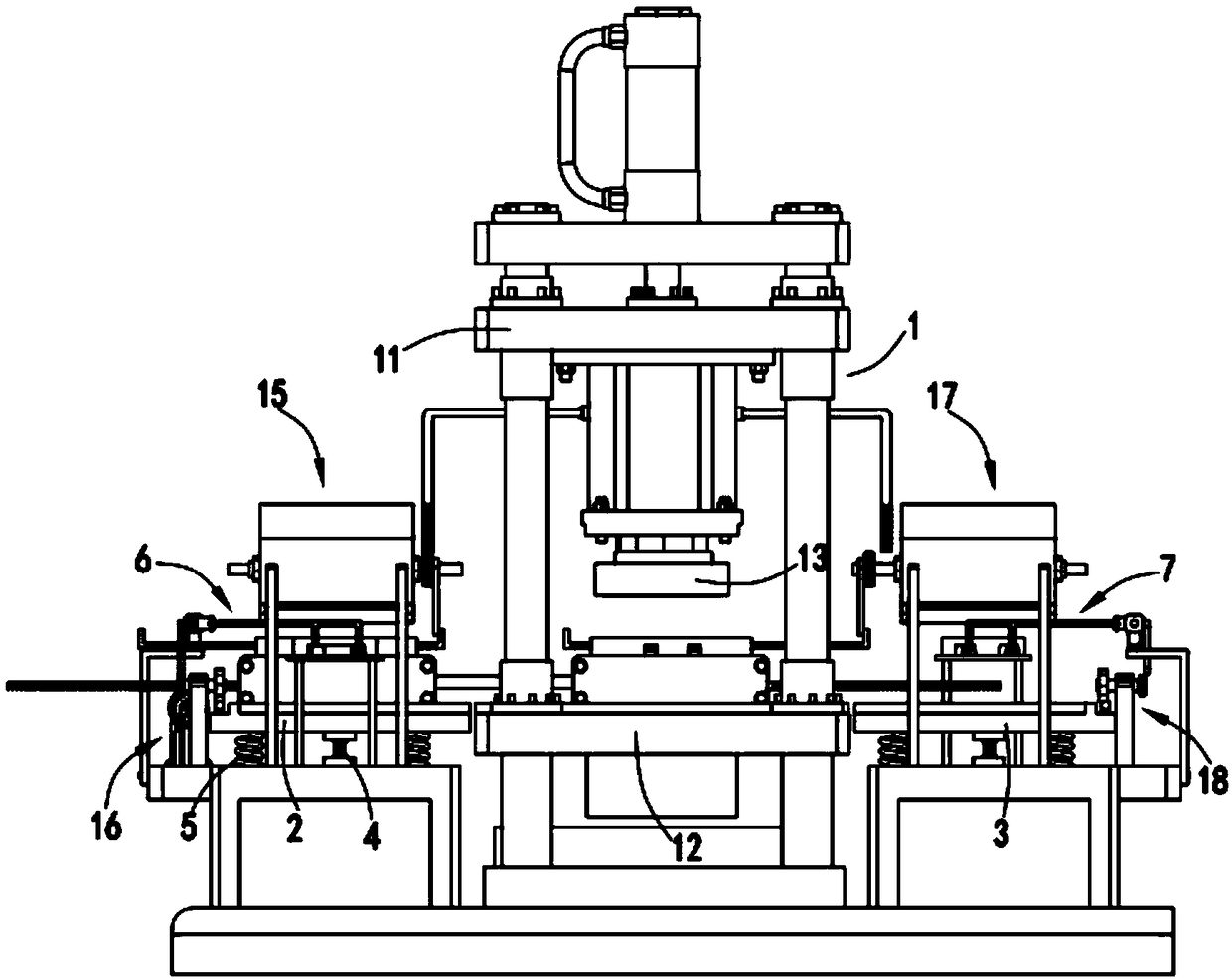

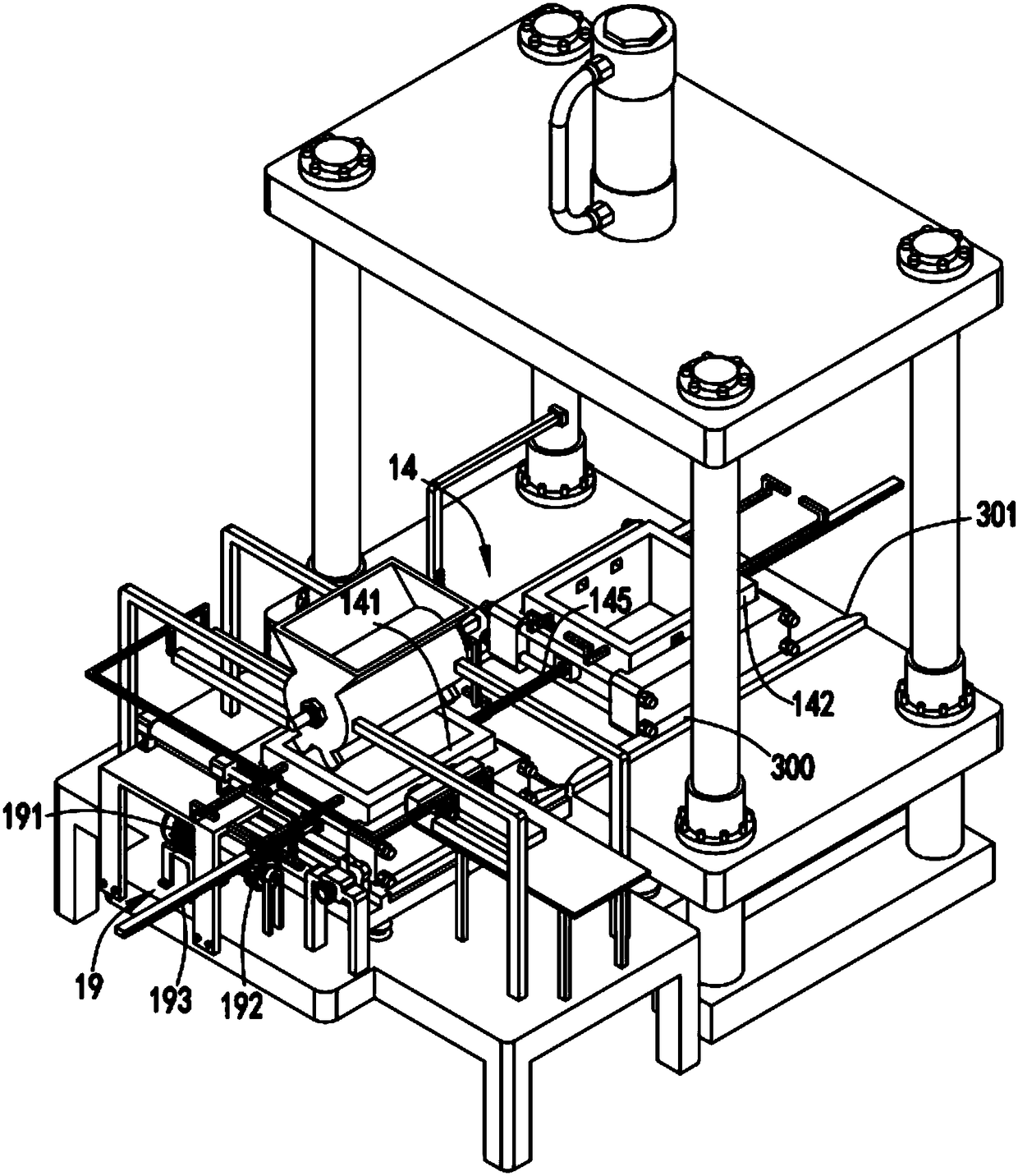

[0046] Such as Figure 1 to Figure 9 As shown, a refractory brick double-station rapid switching molding equipment includes a press 1, and the press 1 includes an upper mold base 11, a lower mold base 12, and a punch 13 arranged on the upper mold base 11. The left and right sides of the press 1 are respectively provided with a charging table a2 and a charging table b3, and also includes a die assembly 14, and the die assembly 14 is mounted on the loading table a2, the charging table b3 and the lower die base 12. slide back;

[0047] The die assembly 14 includes a die a141 and a die b142 that is movably connected to the die a141. Both sides of the die a141 and the die b142 are provided with introduction grooves 100, and in the introduction grooves 100 A mating block 200 mated with the introduction slot 100 is provided;

[0048] A feeding mechanism a15 is also provided above the charging platform a2, and a vibrating mechanism a16 is provided on one side thereof; after the die ...

Embodiment 2

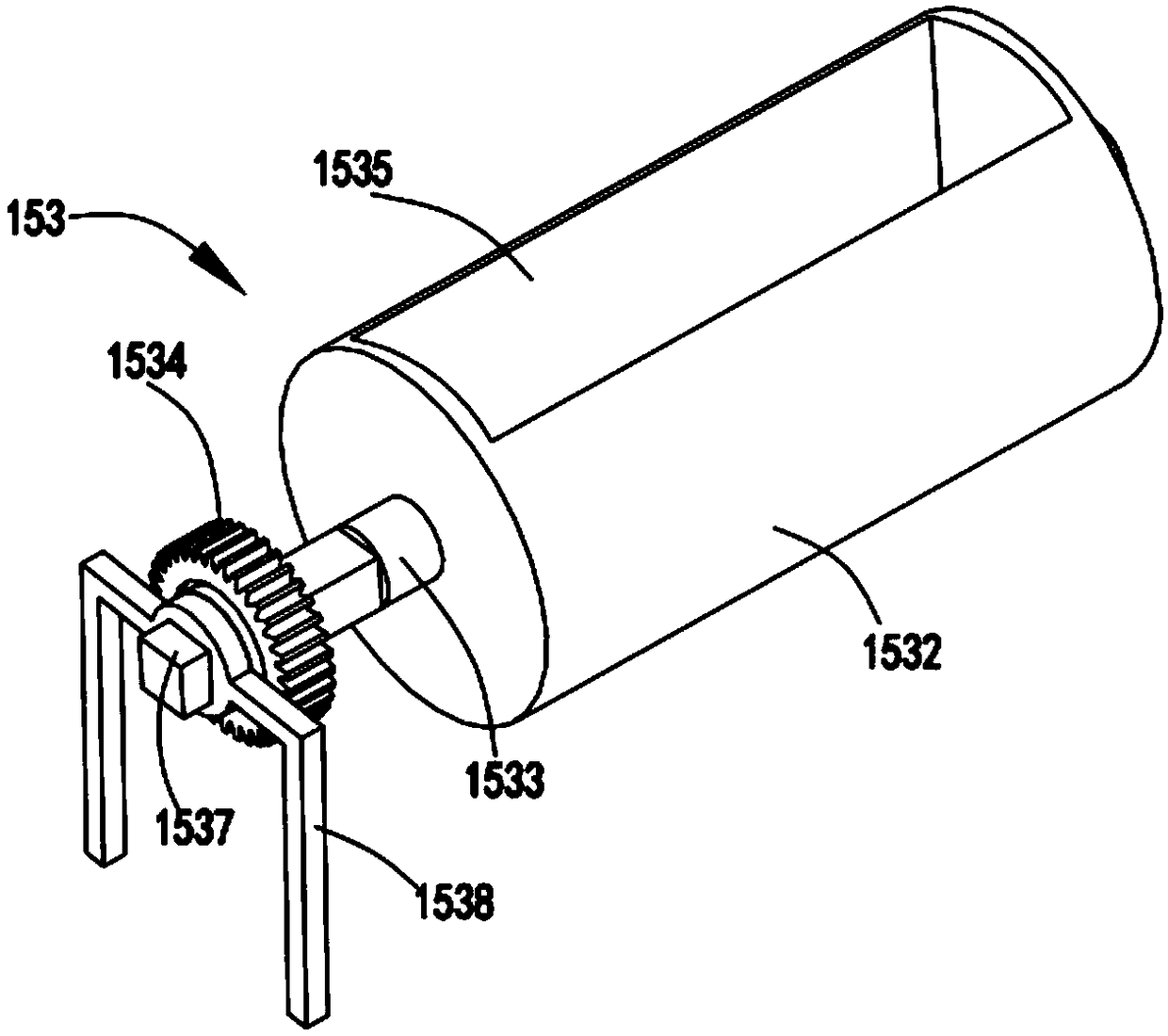

[0070] Such as figure 2 and Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, the quantitative component 153 includes a limiting outer frame 1531, a quantitative barrel 1532 rotatably arranged in the limiting outer frame 1531, and a center of the quantitative barrel 1532. The gear c1534 coaxially arranged with the shaft 1533, the quantitative barrel 1532 is set in a cylindrical shape and its outer wall fits the inner wall of the limit outer frame 1531, the quantitative barrel 1532 is provided with a quantitative groove 1535, and the quantitative groove 1535 faces upward When the material in the hopper 152 enters the quantitative groove 1535, the material in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com