A method for preparing cellulose ether from herbs such as hemp and straw as raw materials

A technology of herbal plants and cellulose ethers, applied in the use of microorganisms/enzyme cellulose treatment, non-woody plants/crop pulp, fiber raw material treatment, etc., can solve the problem of low function of degumming strains, imperfect degumming process, and insufficient enzyme activity Advanced problems, to achieve the effect of complete removal of gum, complete enzyme system and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

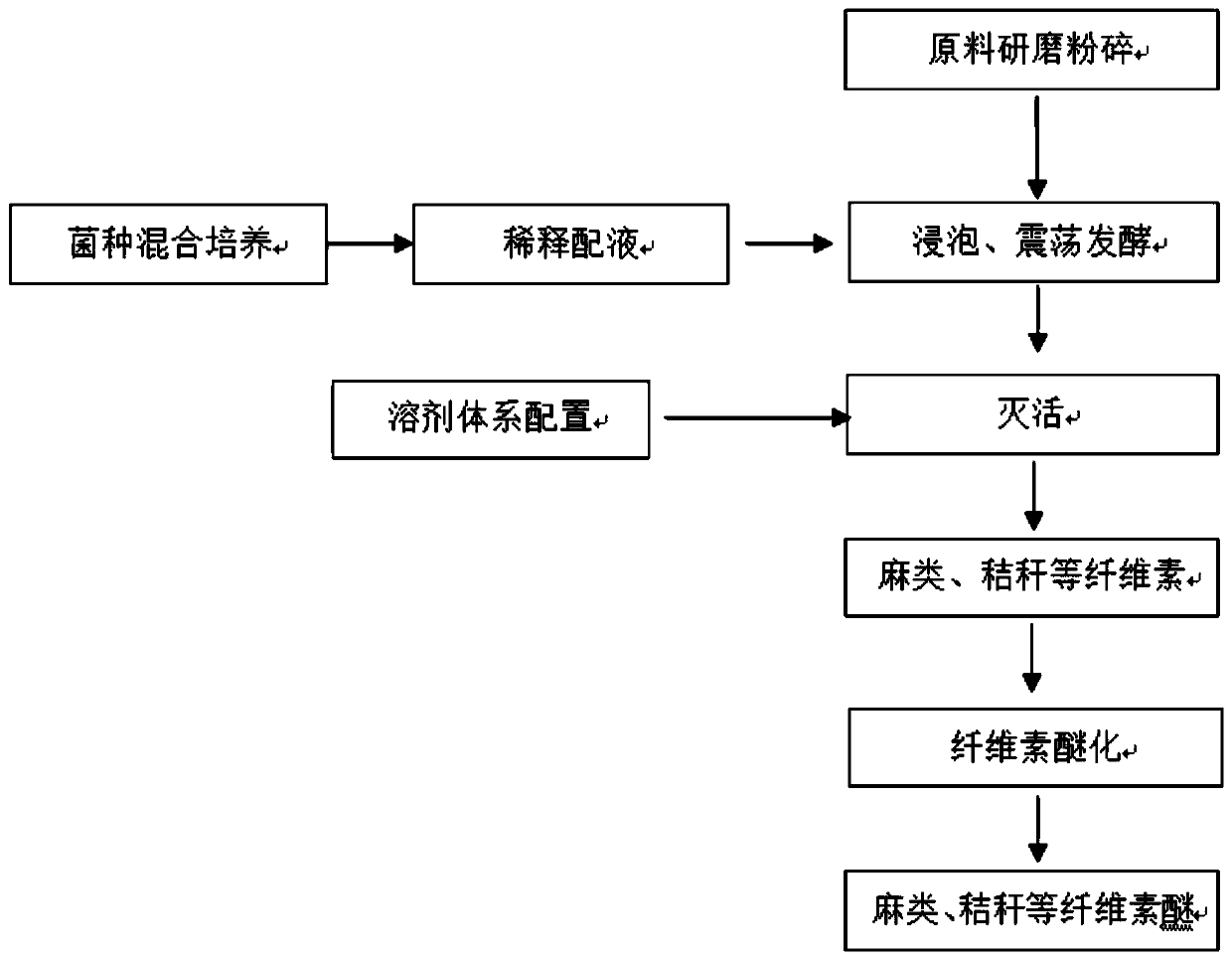

[0042] This embodiment provides a kind of hemp bast ethyl cellulose ether, its preparation flow chart is as follows figure 1 As shown, the preparation method is as follows:

[0043] (1) Raw hemp grinding and crushing

[0044] Sun-dry the mildew-free cannabis bast until the water content is lower than 10%, fluff and remove impurities. Grind it into a fine loose crumb powder with a length of about 2 mm with a plant pulverizer.

[0045] (2) Bacteria culture

[0046] Plant spoilage bacteria PW (Pectobacterium wasabiae IBFC 2016) and Bacillus subtilis BSE (Bacillus subtilis BSE) were mixed and cultured to prepare a bacterial suspension; culture conditions: broth culture solution, pH 7, temperature 34°C, ventilation 0.2~ 0.3m 3 / (m 3 • h) with stirring at 120 rpm.

[0047] (3) Diluted solution

[0048] Pour tap water into the fermenter with heating, stirring and ventilation functions, and adjust to pH 7, temperature 34°C ± 1°C; add 2% of the bacterial suspension obtained in s...

Embodiment 2

[0058] This embodiment provides a kind of sisal leaf carboxymethyl cellulose ether, the preparation method is as follows:

[0059] (1) Raw hemp grinding and crushing

[0060] Dry the mildew-free sisal leaves until the water content is lower than 10%, fluff them and remove impurities. Grind it into a small loose crumb powder of about 2 mm with a plant pulverizer.

[0061] (2) Bacteria culture

[0062] Plant spoilage bacteria PW and Bacillus subtilis BSE were cultured together to prepare a bacterial suspension. Culture conditions: Broth culture medium, pH7, temperature 35°C, ventilation volume 0.2~0.3m 3 / (m 3 • h) with stirring at 120 rpm.

[0063] (3) Diluted solution

[0064] Pour tap water into the fermenter with heating, stirring and ventilation functions, and adjust to pH 7, temperature 34°C ± 1°C; add 2% of the bacterial suspension obtained in step (2) to it, mix and dilute to obtain the total activity Bacterial content of at least 1×10 7 cfu / mL dilution.

[0065...

Embodiment 3

[0074] This example provides a rice straw hydroxyethyl cellulose film ether, the preparation method is as follows:

[0075] (1) Raw hemp grinding and crushing

[0076] Dry the mildew-free rice straw to a moisture content of 8%, fluff it up and remove impurities. Use grinding equipment such as a plant pulverizer to grind it into a fine, loose crumb-like powder of about 2 mm.

[0077] (2) Bacteria culture

[0078] Plant spoilage bacteria PW and Bacillus subtilis BSE were cultured together to prepare a bacterial suspension. Culture conditions: Broth culture medium, pH7, temperature 33°C, ventilation volume 0.2~0.3m 3 / (m 3 • h) with stirring at 130 rpm.

[0079] (3) Diluted solution

[0080] Pour tap water into the fermenter with heating, stirring and ventilation functions, and adjust to pH 7, temperature 34°C±1°C; add 2% of the bacterial suspension obtained in step (2) to it, mix and dilute to obtain the total active Bacterial content of at least 1×10 7 cfu / mL dilution. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com