Wire rope stretching assembling system with centering and aligning functions and assembling method thereof

An assembly system and tensioning technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as hidden dangers in quality, difficulty in repairing tensioned ends of steel cables, difficulties in accurate assembly and alignment, and achieve easy adjustment accuracy , Easy to install, easy to pull the effect of the traction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

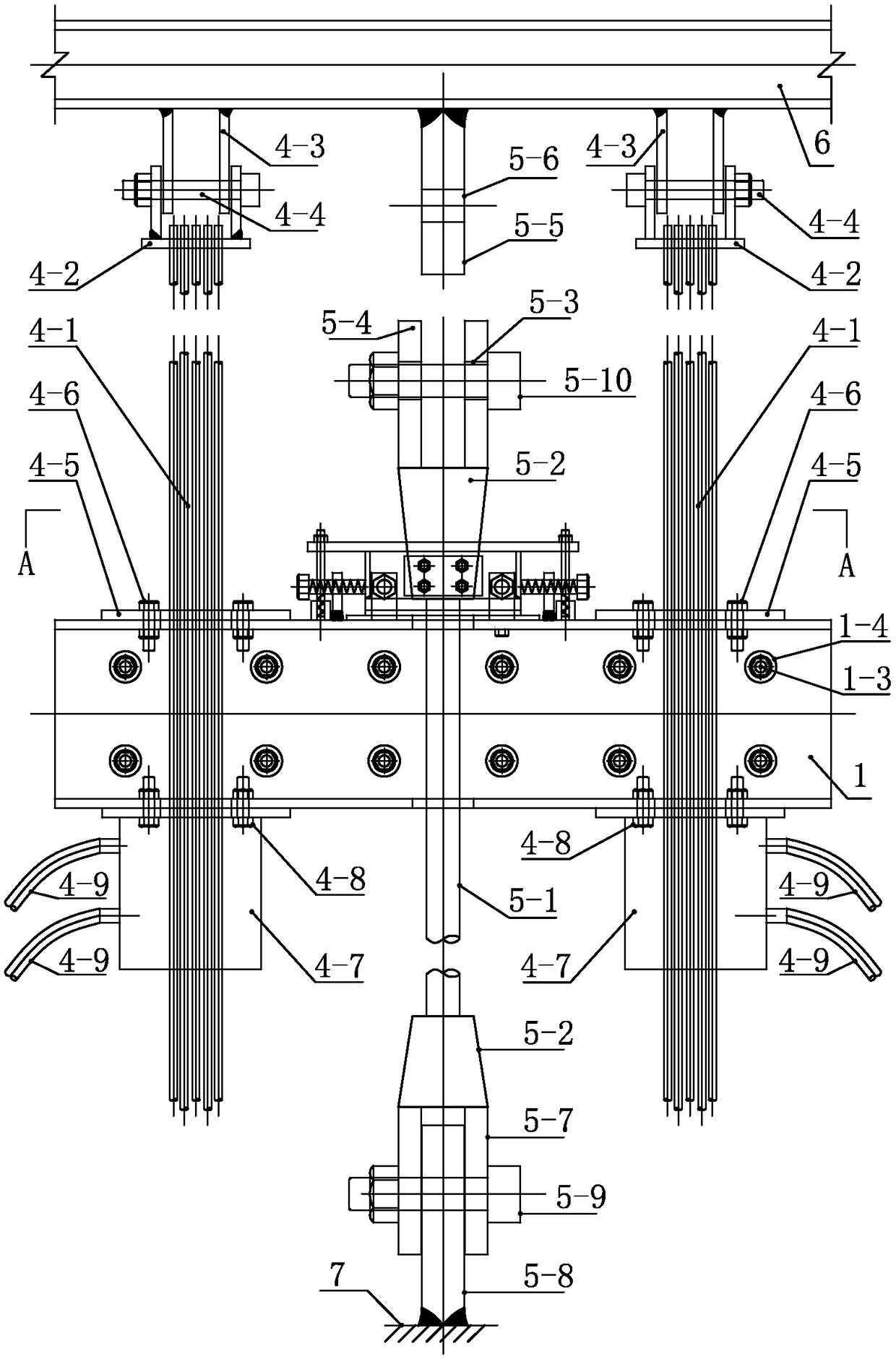

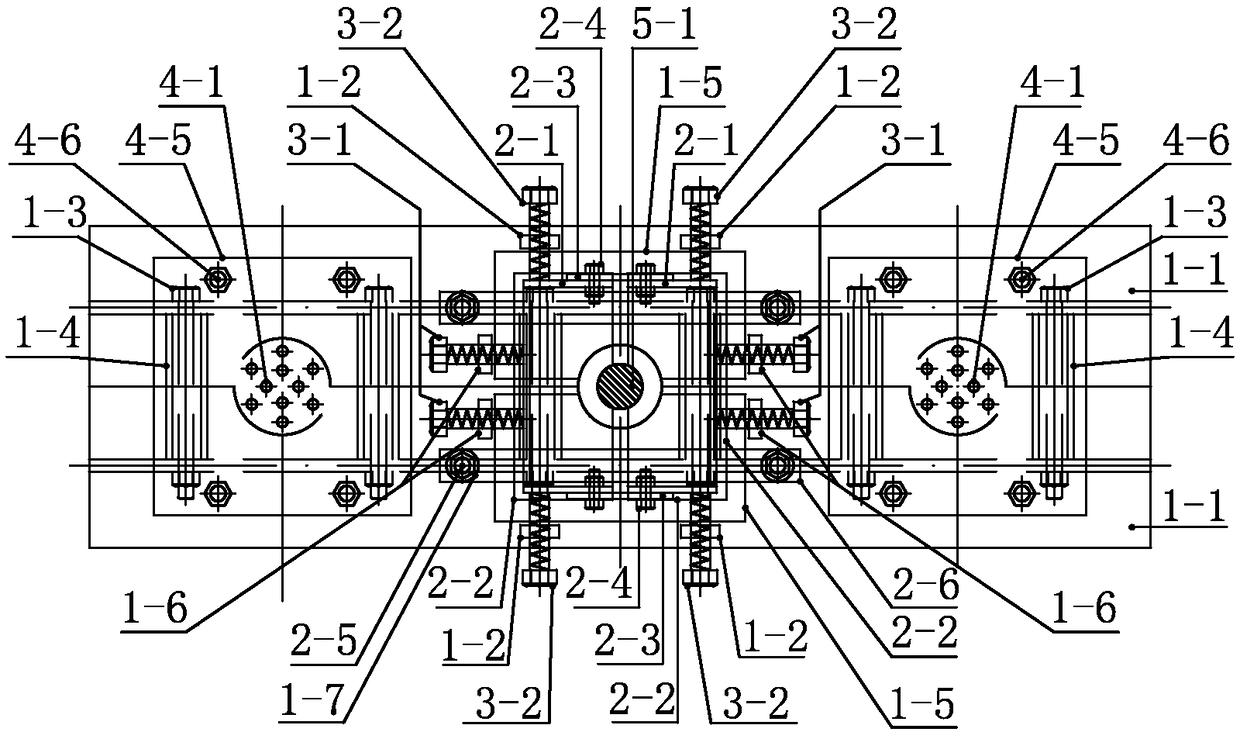

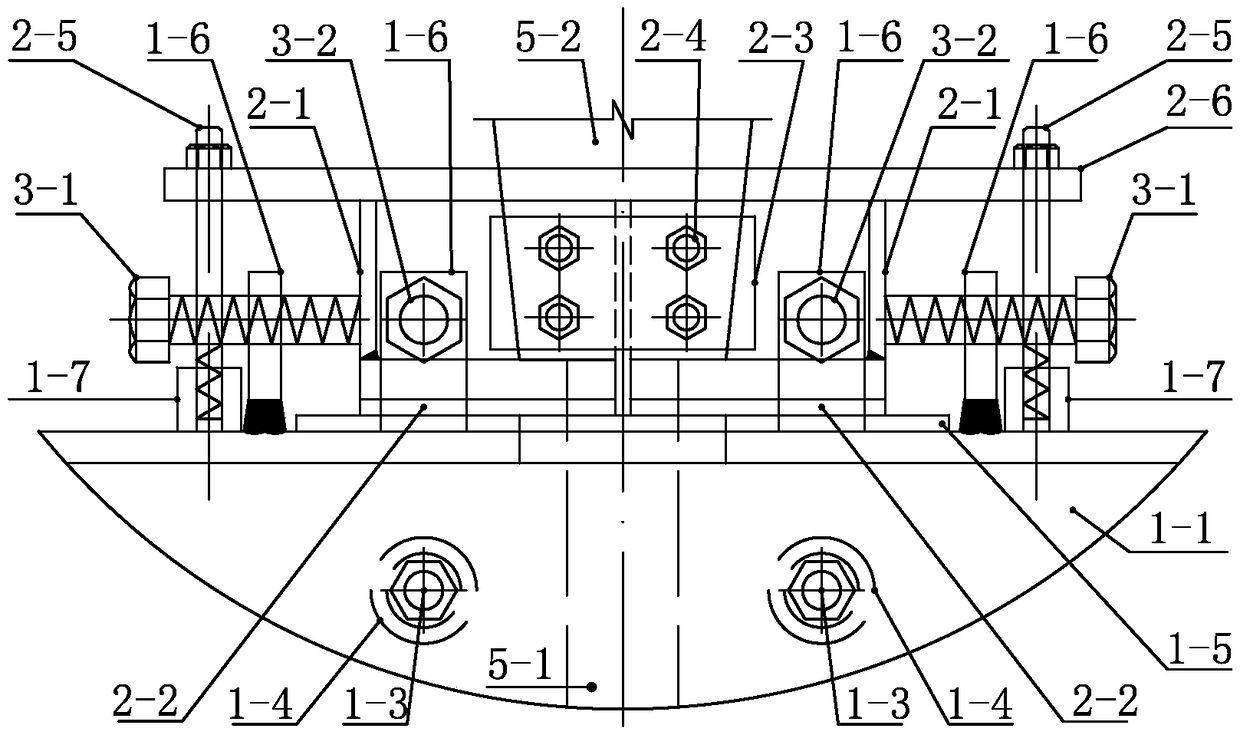

[0063] Such as Figure 1 to Figure 17 Shown is the steel cable tensioning assembly system with centering and alignment functions in the present invention, including the prestressed steel cable assembly and the steel cable fixing system.

[0064] The prestressed steel cable assembly includes the lug plate 5-7 at the starting end of the steel cable, the lug plate 5-4 at the tensioning end of the steel cable, the lug pin shaft 5-9 at the starting end of the steel cable, and the lug pin shaft 5 at the tensioning end end of the steel cable -10, steel cable 5-1, steel cable short sheath 5-2. The steel cable fixing part system includes the starting end fixing part 7 of the steel cable, the fixing part 6 of the tensioning end of the steel cable, the support ear plate 5-8 of the starting end of the steel cable and the support ear plate 5-5 of the tensioning end of the steel cable, and the steel cable The ear plate 5-8 of the support at the starting end is fixed on the fixed part 7 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com